GEA North America: Excellence in Fish Processing and Packaging

This blog post features one of GSA’s Corporate Members, GEA North America. We thank GEA North America for their support of the work GSA does to advance responsible seafood practices.

This blog post features one of GSA’s Corporate Members, GEA North America. We thank GEA North America for their support of the work GSA does to advance responsible seafood practices.

In the seafood processing industry, GEA provides integrated solutions designed to optimize product quality, efficiency, and sustainability at every stage of production. From marination and mixing to forming, cooking, and packaging, GEA’s advanced technologies help processors meet evolving consumer expectations and regulatory requirements.

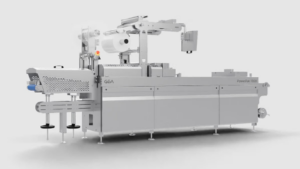

For marination, the GEA MultiJector ensures precise brine distribution, enhancing product consistency and yield while reducing waste. The GEA CutMaster delivers high-performance mixing and emulsifying, enabling efficient processing of a wide range of seafood products. When it comes to packaging, GEA offers two standout systems: the GEA PowerPak thermoformer and the GEA SmartPacker CX400 vertical bagger. These machines are designed for hygiene, speed, and flexibility, helping processors maintain freshness, reduce material use, and improve shelf appeal—all while lowering their environmental impact.

Sustainability is central to GEA’s approach, with a strong emphasis on energy efficiency, resource conservation, and modular solutions that scale with the processor’s needs. Customers can also collaborate with experts at GEA’s Technology Center in Frisco, Texas, where pilot testing and line development allow for optimization before full-scale production.

GEA Group, a global technology supplier to the food, beverage, pharmaceutical, and chemical industries, is structured into five divisions, each focused on specialized areas. Operating in over 150 countries, GEA combines customer proximity, innovation, and operational excellence to deliver sustainable solutions that drive progress across industries.

Thanks for being a member, GEA North America!