Mixing quality

The mixing cost center is considered the heart of the feed-manufacturing process. All ground ingredients are conveyed to the center to be blended into a homogenous feed ration. It is critical that the mixing operation be performed under strict guidelines to avoid undermixing or overmixing, also known as segregation.

Operator responsibilities

Before starting the mixing process, operators must ensure the mixing equipment is in good operating condition. At least every two months, the mixer operator and maintenance supervisor of a plant should check for wear and material build-up on the paddles or ribbons, and in the case of clam-shell or drop-bottom mixers, ensure that gates close tightly. Any such problems can affect the homogeneity of the mix.

Mixer operators are responsible for the cleanliness of their machines. Improperly cleaned mixers can be a source of cross contamination involving antibiotics, mold growth, or aflatoxins, especially in feed mills where other farm animal feed is made.

In pregrinding systems discussed in a previous column, the ingredients are proportioned into one or two weighing scales and then dropped into the mixer. In this type of system, it is very important that the operator check each ingredient bin to make sure it contains the right ingredient. If ingredients are proportioned from the wrong bins, the formula will not meet the nutritional requirements for which it was designed.

Mixer efficiency testing

Every mixer is different in design: Some mixers have ribbons, paddles, or a combination of the two. The type of mixing elements used, as well as their stage of wear, amount of build-up on the paddles, particle size, and density of ingredients all affect mixing efficiency. Thus, mixer tests are critical to determine the time needed to uniformly mix formula.

Mixer tests also determine the most efficient time that ensures the productivity of the plant. A 2-metric tons (MT) mixer with a five-minute mixing time is less efficient than one of the same capacity that can do the job in half the time.

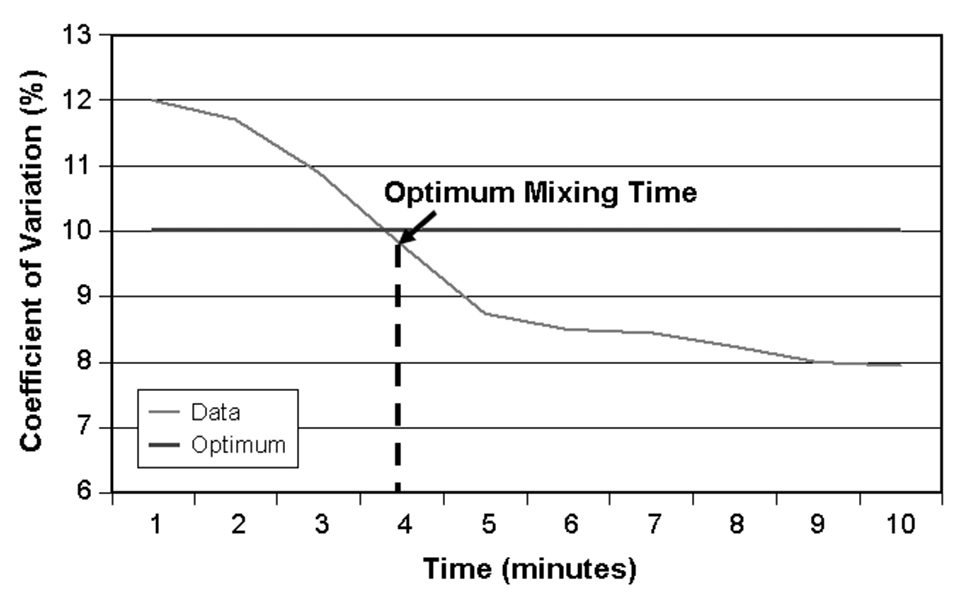

As a rule of thumb, mixer tests should be performed at least twice a year, and preferably every four months. The tests monitor the efficiency of mixers to produce a homogenous blend at different time intervals. Results are measured by the percent coefficient of variation (CV), which is the standard deviation divided by the average of 10 samples at each time interval, multiplied by 100.

A CV of less than 10 percent is the standard used in the feed industry as an indication of a good mix. Therefore, if the CV is less than 10 percent at four minutes, the operator must ensure that each batch is mixed for that length of time. A sample of a mixer data graph showing optimum mixing time is shown in Fig. 1.

It is important that mixer tests are performed with formulas that represent the average density of the various formulas used. An adequate mixer test can not be based only on a single formula, because due to ingredient variations, each formula can have different densities and thus slightly different mixing times. Readers interested in more detailed information on mixer tests should consult Feed Manufacturing Technology IV, available from the American Feed Industry Association, Inc., http://www.afia.org.

Ingredient addition

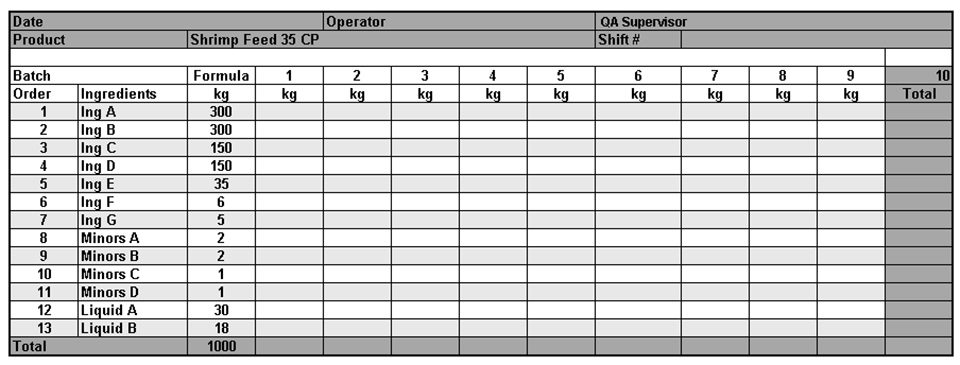

For shrimp feed formulas, mixing should be done in two continuous steps. First, dry mixing in which all major ingredients are added from the largest to the smallest amount, followed by minor ingredients (also largest to smallest). The second step is wet mixing, where liquid ingredients are added.

The sequence of addition of liquid ingredients must also take into account the type of liquid added. Water should be added first to permit the hydration of the dry ingredients, which are mainly cereals and some protein ingredients. Oil should be added last to avoid coating the particles, which could prevent proper ingredient hydration. The mixer is not idle between the two mixing steps, but blends until the total optimum mixing time has been achieved.

In automated mixing systems, the sequence of ingredient addition can be programmed, which gives some comfort to operators that ingredients are coming from the right bins and in the right sequence. However, in manual systems, the mixing operators are responsible for the sequence of addition of ingredients and the amounts being weighed and added to the mixer.

The only way operators have to control the process is by following a checklist that shows the order of the ingredients in the formula, the bin from which each ingredient is sourced, and columns to record the amount of each ingredient used. The latter shows the total usage of ingredients in a shift or day, which can help consolidate ingredient inventories. An example of a mixing checklist is shown in Fig. 2. If a mistake is made, the operator should record it, divert the incorrect mix to a holding bin for reprocessing, and report immediately to the quality supervisor.

Ensuring quality of mixed formulas

To make sure a formula has all the ingredients in the right amounts, random samples of the mix must be collected for each product made. The samples should be collected as close as possible to the mixer discharge through a sample port located at the mixer discharge or in the conveying system.

The locations of sample ports should provide safe, easy access, and the persons who collect samples should always be watchful for moving mechanical parts. Collection ports that draw sample by gravity are better than those that introduce sampling probes into the equipment. At all times, operators and quality-assurance supervisors should avoid inserting their hands into the sampling ports.

It is very important to properly label samples with information about the formula type, batch number, and date that corresponds to the finished product. Collected samples should be sent for analysis to the laboratory.

The lab results must match the proximal analysis of the formula. If they don’t, the finished product corresponding to the run number, formula type, and date of the sample should not be allowed to leave the plant. Samples from the finished product should be further analyzed, including amino acid and fatty acid profiles, and then reused in future runs of the same formula.

Mixing mistakes should be avoided at all costs, because they directly affect the efficiency of plants. When a finished product is reprocessed, it must be reground, mixed, and conveyed. The inclusion level of reprocessed ingredients should not be more than 3 percent to maintain the quality of the final product. This is particularly relevant with starches, which lose their binding capacity once subjected to water and temperature. If too much reprocessed ingredient is included, it could affect the water stability of the feed.

Conclusion

In the mixing cost center, it is important to achieve a homogeneous blend and ensure that the right ingredients in the right amounts have been used. Properly proportioned ingredients, together with adequate mixing time, will ensure the production of formula that meets the nutritional standards for the species and growth stage for which it was designed.

(Editor’s Note: This article was originally published in the December 2003 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Eugenio J. Bortone, Ph.D., PAS

5416 Lafayette Lane

Frisco, Texas 75035 USA[109,111,99,46,108,105,97,109,103,64,101,110,111,116,114,111,98,114,100]

Tagged With

Related Posts

Aquafeeds

Inline quality assurance, part 3

In the pelleting cost center, the ingredient mixture is placed in a holding bin above the pellet mill until it is pelleted.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

Animal byproduct concentrates useful tools in formulation

With the market volatility of fishmeal, as well as rising sustainability concerns, the aquaculture industry is seeking sources of protein, such as animal byproduct concentrates, to substitute for fishmeal.