Proportioning and grinding

The starting point for quality feed is quality ingredients. However, starting with high-quality ingredients does not ensure high-quality feed unless strict guidelines are implemented in each of the processing cost centers.

Process optimization

The first step for inline quality monitoring is the optimization of each of the processes used to make the feed. Its purpose is to define the processing parameters where a maximum throughput is achieved to produce the highest possible product quality.

The latter is a concept sometimes difficult to grasp by plant and production managers, who often seek to simply boost capacity as a measure of plant productivity. The real measure of productivity of any feed mill should be based on achieving the highest quality at the maximum capacity, with quality the driving force.

Process optimization can provide the guidelines or range of processing parameters to consistently produce quality feed. It can also be used as a tool to determine the robustness of the process under a range of processing conditions. A small change in processing parameters can produce measurable effects on product quality.

However, successful inline quality-assurance programs must also have committed personnel. This requires giving operators proper training on equipment performance and how it affects quality. Operators should also have full responsibility for the equipment to make sure it is maintained and operated properly.

No quality-assurance program will work if the company does not endorse it through strict guidelines enforced by a Quality Assurance (QA) department responsible for overseeing that every step of the process stays within the specified quality parameters. The QA department, not the production manager, should have the final word on what products are cleared for sale or dispatched to clients.

Each of the cost centers – proportioning, grinding, mixing, pelleting, and packaging – has a process and a product produced. These products can be defined as a blend of ingredients, the ground ingredients, pelleted feed, crumbles, and the final bagged feed.

Proportioning cost center

In the proportioning cost center, all the ingredients in the formula are weighed to form a formula mix “product.” To ensure the process is properly done, the operator must register the sequence of ingredients weighed and make sure the weights correspond to the formula.

The operator is responsible for transferring raw materials from the bulk storage to the proportioning bins. He or she is also responsible for checking that all magnets and scalpers are cleaned, that ingredients are placed in the right bin to avoid cross-contamination, and that the scales are functioning properly. Similarly, the operator must ensure that dosing bins are maintained and cleaned, so that no material hang-ups are left to spoil in the dead spots of the bins.

At the same time, QA works hand in hand with the operator to monitor the process by collecting samples of the ingredients for later analysis for cross-contamination. Good record keeping is critical at every step of the process. The QA person must record times, dates, formula identification numbers, and batch numbers. The operator, at the same time, labels all the samples with the corresponding formula identification and batch numbers. This information can be later correlated with the rest of the process and used to determine if anything was improperly done or outside established standards.

Substandard product

The most-common mistake in the proportioning cost center is the inclusion of incorrect raw materials as a result of dosing from the wrong bin or because the operator filled the bin with the wrong ingredient. A careful analysis, with proper record keeping, can prevent finished products outside the standards from reaching shrimp farms.

In most cases, these out-of-standard products should not leave the plant, or be recalled if they were dispatched to farms. However, the latter should never be allowed, for all product should be cleared for sale by QA prior to dispatch.

The best way to accomplish this is to have enough finished product capacity to store the feed for at least a week, which gives plenty of time for QA to do all the respective analyses. Production managers should schedule the dispatching of finished products based on a first-in, first-out flow. Once QA has cleared a finished product, it should be available for delivery based on production date, and batch and formula numbers.

Recalled product that is still considered fresh can be reutilized in the formulas. The first step for including a finished product in a formula is to identify the nutritional parameters (crude protein, fat, ash, etc.), cost including reprocessing, and overall quality.

Once the finished product is cleared for use as an ingredient, it should be assigned to a reprocess bin and included in the formulation using the standard strict guidelines. Because this is a processed ingredient, its inclusion level should not exceed 2 percent to avoid affecting physical parameters like water stability. The level of reprocess should not exceed 0.5 percent of the total feed produced.

Grinding cost center

Once the preblended mix reaches the grinding cost center, the process is “owned” by the mill operator. This cost center is the most critical step of the process, for any deviation from the target particle size can affect the nutritional and physical properties of the feed and drastically affect the process downstream. The operator is accountable for the proper maintenance and functioning of the grinding equipment, and also for ensuring that the blend is ground within standards.

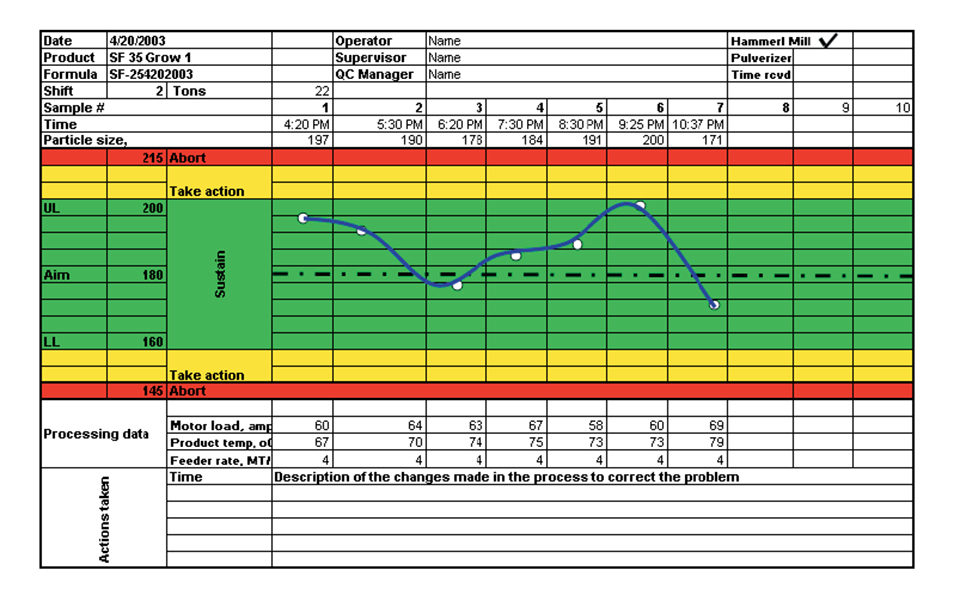

Figure 1 shows a sample table for data collection in the grinding cost center, set up to capture target particle size and upper and lower limits. The standards for particle size limits should be based on previous optimization runs with similar ingredients. Once the processing parameters and standards are established, the operator should be able to obtain the same quality product, allowing for small modifications due to wear of the screens and hammers, as well as changes in the physical properties of some ingredients in the formula.

In the grinding process, it is critical to collect data at least every hour. This can be done by setting up sieve analysis in the grinding room that gives the operator data to monitor the process in real time. Upon completing the sieve analysis, the operator should submit samples to the QA department in bags labeled with the dates, times, and formula identification codes.

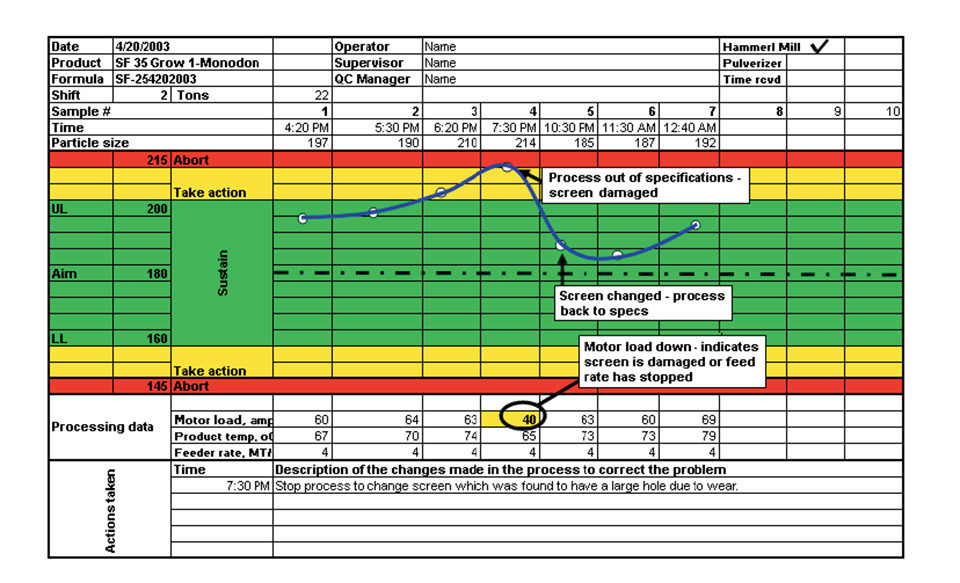

Fig. 1 shows data typical for a process running under normal conditions in which the product attributes stay within the green optimum range. In contrast, the process in Fig. 2 is out of the specified green range four hours into the run. It is obvious from the data that something caused the particle size to exceed the upper limit.

According to the data, the motor load dropped to 40 amps from a normal rate of 63 to 70 amps load. This was indicative of a broken screen, which the operator was able to detect on time thanks to the inline process control with the sieve analysis. Once the grinding was resumed with the new screen, the operator was able to determine the particle size was back in the desired green range.

With proper data collection, inline quality control can also be an important tool for preventive maintenance. The data can tell operators the approximate number of run hours or tons that wear out the parts. This information is useful to program ahead of time changes of screens or hammers. Therefore, the operators can take preventive measures to avoid surprises in the process that increase down time and reduce the overall efficiency of the grinding cost center.

Conclusion

Process quality control is a commitment that needs to be embraced by the whole organization within a facility, from the president to the operator. All personnel should be properly trained and have clear accountabilities in their respective cost centers. Proper testing equipment, defined product standards and process parameters, and all the necessary forms to record process performance are also very important. Quality departments should perform periodic compliance inspections to ascertain quality standards are consistently met.

(Editor’s Note: This article was originally published in the August 2003 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Eugenio J. Bortone, Ph.D., PAS

5416 Lafayette Lane

Frisco, Texas 75035 USA[109,111,99,46,108,105,97,109,103,64,101,110,111,116,114,111,98,114,100]

Tagged With

Related Posts

Aquafeeds

Inline quality assurance, part 2

The mixing cost center is the heart of the feed-manufacturing process. It is critical that it is under strict quality assurance guidelines.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

Inline quality assurance, part 3

In the pelleting cost center, the ingredient mixture is placed in a holding bin above the pellet mill until it is pelleted.