Species coveted by live markets

inserted.

Live Kuruma shrimp (Penaeus japonicus) are highly prized in Japan as the “King of Marine Foods.” They usually command very high prices at top restaurants and celebration banquets, and the culture and marketing of this species preferentially targets these selective markets over increased production for the general public. While the contribution of cultured Kuruma to world shrimp production has remained less than 3 percent, P. japonicus has its advantages.

Among penaeids, this is the only species that tolerates transportation over long distances and without water. Fishermen always hold the shrimp live in their boats while they take them to port for auction. The prolonged spawning season of P. japonicus lasts for about six months. Females of the species have a closed thelycum that holds a spermatophore firmly.

The ready supply of mature, mated females facilitated pioneering research by Dr. Fujinaga, who was the first to successfully raise penaeid shrimp through the larval stages. He is generally recognized as the “father” of shrimp farming.

Industry development

After 30 years of research with Kuruma shrimp, Fujinaga and his colleagues launched a commercial shrimp farm in 1963. They decided to adopt a semi-intensive culture method, based on primary production and the use of large outdoor ponds, instead of following Fujinaga’s initial idea to develop an extremely intensive production system. Most of the conventional farms that followed him constructed their ponds on discarded salt beds or sandy beaches.

Larval rearing

In 1964, J. Kittaka developed a technically new approach to larval rearing in large outdoor tanks of over 200 square meters. A moderate phytoplankton bloom was induced using fertilizers applied directly to the same tank where shrimp larvae were to be raised. Larvae fed on growing microorganisms that formed a balanced community in the tank.

The adoption of brine shrimp for early stages of postlarvae was instrumental in the success of the system. The ease of obtaining gravid females and the disseminated hatchery technologies allowed many farmers to produce the postlarvae themselves for several years.

Nutrition

A. Kanazawa, O. Deshimaru, K. Shigueno, and their colleagues determined the nutritional requirements of P. japonicus and contributed to the commercialization of artificial diets for the species. In contrast to other penaeids, they determined the dietary protein level required for this shrimp was as high as 55 percent.

Introduction of round ponds

tanks.

In 1973, the new farm of Mitsui Norin Marine Co. Ltd. was established on the southern tip of mainland Japan. It used 14 round, double-bottomed tanks built after Shigueno’s design. He knew from previous experience that this system was more productive than the conventional pond system, although the initial cost is higher (Fig. 1). The merits of this system, including easier water exchange, draining of sludge, and maintenance of the aerobic sand bed filter, contributed to the increased production.

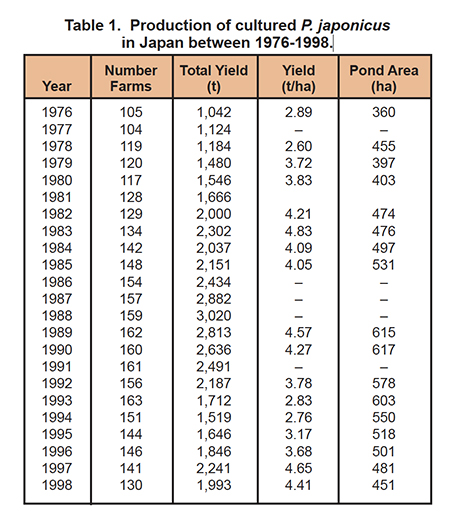

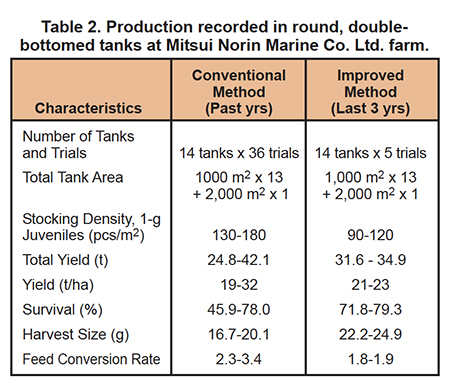

Pond production of shrimp by most other farmers ranged between 2.6 and 4.6 tone per hectare during the 1970s and ’80s (Table 1). Early yields at the Mitsui Norin Marine farm (19 to 32 tons per hectare, Table 2) far exceeded those of other farms.

However, its excessive water exchange hampered the maintenance of phytoplankton, and heightened stress to the shrimp. As a result, survival rates fluctuated 46 to 78 percent due to the frequent occurrence of vibriosis and fungal diseases. Aquatic weeds propagated in tanks, and feed conversion (FCR) increased to 2.3 to 3.4.

WSSV strikes

Tragedy hit western Japan quite unexpectedly in 1993, when some farms imported juveniles from a neighboring country to expedite the start of a culture. Mass mortalities occurred within a few days after the release of these juveniles into grow-out ponds. The culprit for the infection was subsequently identified as White Spot Syndrome Virus (WSSV). Out of 96 nearby farms, 19 were severely affected and forced to abandon their farm business. The epizootic spread throughout the area, and 10 more farms shut down within a few years.

Improved management

After the 1993 WSSV outbreak, the manager of the Mitsui Norin Marine farm drastically improved pond management. Afraid to introduce WSSV, he stocked ponds with virus-free larvae checked by polymerase chain reaction testing, and drastically reduced water exchange rates to a sixth of previous years. A probiotic product was applied to tanks early on, and effective application of chemical fertilizers continued during the culture cycle.

Moderate phytoplankton densities (40 to 60 cm Secchi disk transparency) predominated throughout the culture seasons. Additionally, a ferrous product used in paddy fields to absorb hydrogen sulfide in the soil was used in the 10-cm-thick sand bed, placed above a false bottom.

All these joint measures minimized obnoxious aquatic weeds, reduced feed conversions, almost eliminated disease, and improved overall performance. In addition, organic sludge apparently diminished after each crop. Target production for the next few years is expected to increase as the farm approaches a closed recirculating system.

Selective breeding

There is one notable farm in Japan where selectively bred, sixth-generation, WSSV-free P. japonicus broodstock are maintained, and postlarvae from this farm have recently been sold to many farms. According to the farm manager, the growth rate of shrimp in his grow-out ponds apparently increased, though this has not been definitively determined. He said some shrimp that spawned in March reached 70 grams or more by October.

There is one notable farm in Japan where selectively bred, sixth-generation, WSSV-free P. japonicus broodstock are maintained, and postlarvae from this farm have recently been sold to many farms. According to the farm manager, the growth rate of shrimp in his grow-out ponds apparently increased, though this has not been definitively determined. He said some shrimp that spawned in March reached 70 grams or more by October.

Suggested improvements

The water system of the double-bottomed tanks should be further improved to keep the sand bed more aerobic, by reversing the passing water in an upward direction. More importantly, the high nutrient levels thought to be required to grow this species should be reassessed, in order to reduce nutrient loads in effluents.

Although the need of clean sand beds to grow this species makes their production system and management more complex than those for other penaeids, I believe that the continuously improving technology in those farms will promote future expansion of Kuruma culture in Japan.

Conclusion

The Kuruma shrimp comprises only a small percentage of global aquaculture production. However, it is highly esteemed in the live market in Japan, where it commands high prices. After an outbreak of WSSV in Japan in 1993, pond management methods were modified to increase biosecurity and production rates. These improvements are leading to expanison of Kuruma culture in Japan.

(Editor’s Note: This article was originally published in the February 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Kuni Shigueno, Ph.D.

Kagoshima City, Japan

[112,106,46,101,110,46,110,111,105,100,46,55,102,64,111,110,101,103,105,104,115,107]

Tagged With

Related Posts

Health & Welfare

Challenges to commercializing shrimp triploidy

Once satisfactory performance is demonstrated in commercial larval rearing and grow-out, automated induction will finalize the triploidy commercialization.

Health & Welfare

Developmental transcriptomes from penaeid shrimp

To develop an alternative mechanism for genetic copyright of improved shrimp lines, the authors used a bioinformatics approach to identify germ line genes that could be potentially targeted to ablate the germ line.

Health & Welfare

Effect of dietary methionine on Pacific white shrimp juveniles

This study tested five diets formulated with increasing levels of methionine (Met) and Met + cysteine (Cys) and their effect on growth performance of juvenile Pacific white shrimp stocked at 50, 75 or 100 animals/m2 in a green water system.

Intelligence

Paradigm shifts in shrimp farming

In the evolution of shrimp farming, white shrimp emerged as the primary species. While some farms in the Americas successfully converted to intensive practices, wide adoption has been limited.