Salmon industry and environment stand to benefit by supercooling salmon before transport

If all Norwegian salmon production was supercooled before transport, the industry could save NOK 1.5 billion (U.S. $150 million) annually in transport costs, according to a recent report from food research institute Nofima.

“Supercooling eliminates the need for ice in the crates, thus allowing for more salmon in each crate,” said Nofima scientist Bjørn Tore Rotabakk. “More fish in each crate reduces transport needs, energy consumption and transport costs. It also significantly reduces the use of packaging.”

Fish does not freeze until it reaches a temperature of between 0.5 and minus-1.5 degrees-C (32.9 to 34.7 degrees-F). When fish are quickly cooled to a temperature between 0 degrees-C (32 degrees-F) and their freezing temperature, it’s called “supercooling.” Cooling is achieved by using subcooled liquid, dry ice or freezing technology. After supercooling, the product is packed and transported and the temperature is constantly kept as close as possible to 0 degrees-C (32 degrees-F).

Commissioned by the Fisheries and Aquaculture Industry Research Fund (FHF), the study focused on the economic and environmental effects of supercooling salmon. Looking at two important product flows – salmon to Europe by truck and salmon to Asia by air transport – the findings indicate that both the salmon industry and the environment stand to benefit from using supercooling.

“Supercooling will reduce packing and distribution costs by almost 70 øre (U.S. $10) per kg produced for lorry transport to Europe,” said Audun Iversen, Nofima scientist. “If all Norwegian salmon production was supercooled before transport, the industry could save NOK 1 billion (U.S. $100 million) in transport costs. Savings on air transport are even greater: around 2.70 (U.S. $0.38) per kg, or around half a billion (U.S. $50 million) for the entire industry.”

By using less ice, the industry saves money on ice production, keeping the ice cooled and transporting it all the way to the market.

“Without ice, each crate can contain more fish,” said Iversen. “In turn, this makes it possible to fill vehicles and planes with more fish. Consequently, fewer lorries are required. This will also reduce packaging use and reduce shipping costs.”

He points out that supercooling can reduce the use of packaging and transport by up to 20 percent. This means that around 15,000 truckloads of salmon, and as many returning lorries, can be removed from the roads. There is also the transport of crates from crate factories to slaughterhouses. Other benefits of supercooling salmon before transport include reduced energy use and greenhouse gas emissions.

“Transport to the market accounts for only 1 percent of the total emissions for salmon transported by lorry to Europe, while feed accounts for almost 70 percent of emissions,” said Iversen. “On the other hand, when fish are sent to Asia by plane, transport accounts for more than half of the emissions. Therefore, a change of 17 percent also has a major impact on total emissions, which are thus reduced by almost 8 to 9 percent.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Responsible Seafood Advocate

[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,114,111,116,105,100,101]

Tagged With

Related Posts

Intelligence

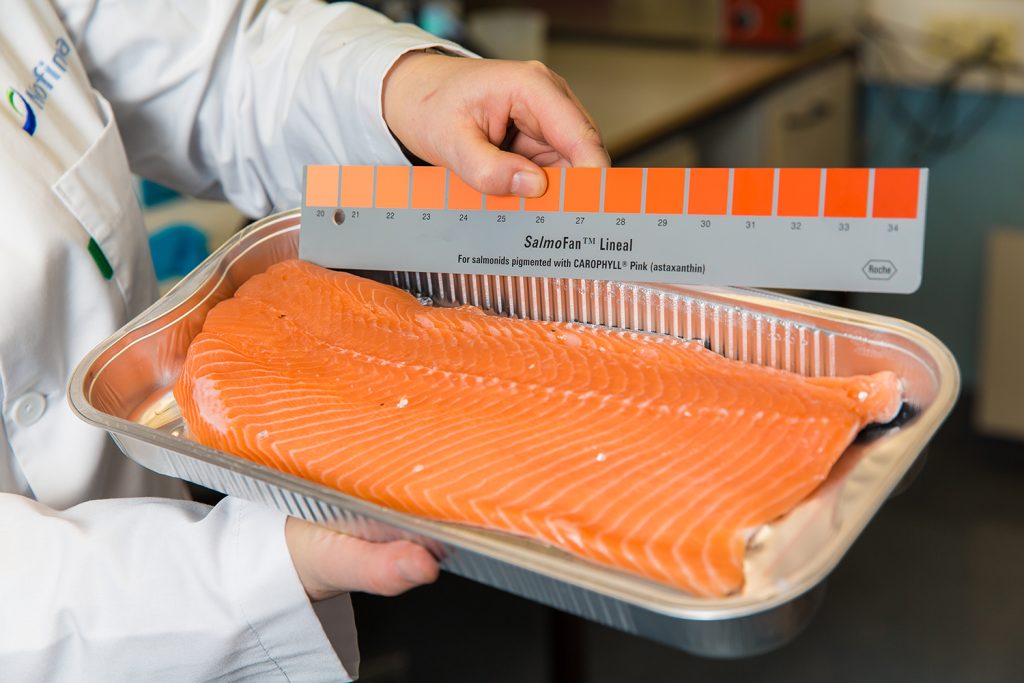

The color of salmon: How fish farmers can add value by focusing on pigmentation

Are Norwegian salmon fillets getting paler? Researchers there are poring over pigmentation data to find commonalities in the color of salmon.

Responsibility

Could a new ‘spill box’ tool lead to zero fish feed waste in land-based aquaculture facilities?

A new tool called the "spill box" separates uneaten fish feed from the aquaculture wastewater so it can be recycled back to the salmon.

Responsibility

‘They thought we were crazy’: Behind one Faroe Island salmon farmer’s bold stance to reduce its carbon emissions

Hiddenfjord executive’s insistence that “fish should never fly” flies in the face of industry norm. This Faroe Island salmon company intends to do things greener.

Aquafeeds

Report: More Norwegian salmon feed producers are using novel fish feed ingredients

A Nofima report reveals that Norwegian salmon feed producers have started to use novel fish feed ingredients.