Study discusses the potential of digital twin technology as the key to ushering in a new era for the aquaculture sector

A new study claims that introducing digital twin technology for aquaculture is essential to growing the intensive fish farming sector. The study, published in Computers and Electronics in Agriculture, was conducted by scientists from several research institutions in Norway, Belgium and Greece.

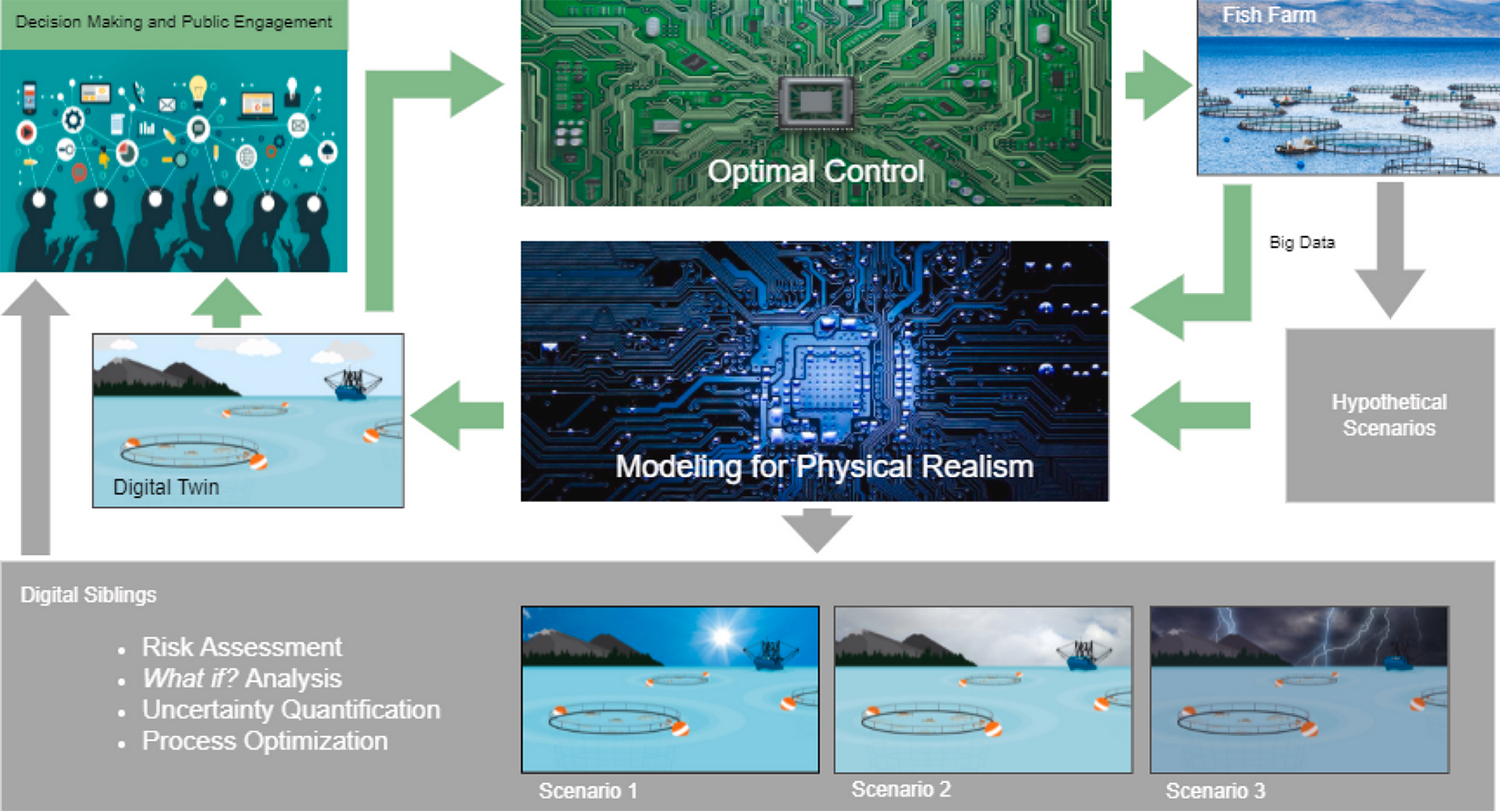

A digital twin is a computer program that offers a digital representation of a real-world system or asset of interest that merges mathematical models (knowledge based and data driven models) of that system with real-time data from the system. It’s like having a virtual copy or simulation of a physical object, process or system. It mimics the real thing in digital form, allowing you to monitor, analyze and optimize performance without directly interacting with the physical object.

In the context of aquaculture, digital twin technology can be applied to various aspects of fish farming, such as monitoring environmental conditions, resource management and predictive analytics. The research team says this could a key enabling technology to achieve the aims of “Industry 4.0” – the ongoing fourth industrial revolution characterized by the integration of digital technologies into manufacturing and other industrial processes.

“Digital twin solutions that merge real time observations through in-farm instruments with predictive models based on existing system knowledge will provide deeper and more precise insights into the biological and physical dynamics of fish farms,” said Dr. Martin Føre, leading author of the study, told the Advocate. “Such solutions can in turn be used as a foundation for the future automation of farming operations through feedback control, which will become increasingly relevant as farming operations are moved further from shore and/or into more exposed conditions.”

While the capabilities of digital twins developed and applied in many fields are increasing rapidly, there have been few attempts at using digital twin technology for aquaculture applications. One of the main reasons for this is probably that intensive aquaculture is a comparatively young industry. Most early research and development efforts in aquaculture have accordingly had to focus on solving the concrete biological challenges of underwater animal production.

However, many of these challenges have now been overcome, and the industry is at a point where the focus is shifting to developing farm management practices to better monitor and control production.

Due to the rapid ongoing development in technological methods in aquaculture, the digital twin technology building blocks required for aquaculture are becoming available.

The research by Dr. Føre and his co-authors presents case studies that explore digital twin technology for three application areas of high industrial relevance: how to improve monitoring of oxygen conditions in sea-cages, how to better obtain real-time inputs on fish growth and biomass development in these cages; and the increased use of robotics and autonomous vehicles in aquaculture, particularly when considering moving production to less accessible and exposed locations.

“The main conclusion of this study is that the technological level within aquaculture is sufficiently high to warrant starting the work on adapting digital twins,” the authors concluded. “Furthermore, given the potential benefits, this is a path the scientific community and industry alike should start following. This requires that research and development processes are adjusted to not only focus on their specific goals, but also on how the outcomes will fit in a holistic digital twin solution down the line. If we can integrate this vision into the future of research and innovation in aquaculture, it is likely that the future will see us able to harvest the benefits of digital twin technology also within this sector.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Darryl Jory, Ph.D.

Editor Emeritus

[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,121,114,111,106,46,108,121,114,114,97,100]

Tagged With

Related Posts

Intelligence

Remotely operated vehicles are helping aquaculture gain a deeper understanding of the seabed

Experts are using remotely operated vehicles to map and monitor the seabed, which could produce information to inform aquaculture operations.

Aquafeeds

Aquafeed moonshots at the F3 ‘talent show’

At the F3 (fish-free feed) Companies Got Talent event in Burlingame, Calif., last week, alternative (non-marine) aquafeed ingredient companies spoke of decoupling aquaculture from fishmeal and fish oil in their quest for greater sustainability.

Responsibility

App aims to bring clarity to seafood traceability, social compliance data

For small-scale aquaculture farmers in far-flung regions, creating traceability data can present major challenges, both linguistic and technological. It’s those challenges that VerifiK8 is poised and ready to help solve.

Intelligence

Startup awarded $1 million to create a ‘digital twin’ of the North Pacific Ocean

PolArctic is using AI to create a "digital twin" of the North Pacific to understand and prepare for the impacts of climate change.