Inaugural ceremony showcases the aquaculture technology of the future

Homegrown Shrimp USA in late March hosted an opening ceremony for its first shrimp farming facility in the United States, located in a rural cattle and citrus farming community in the heart of Martin County in southern Florida.

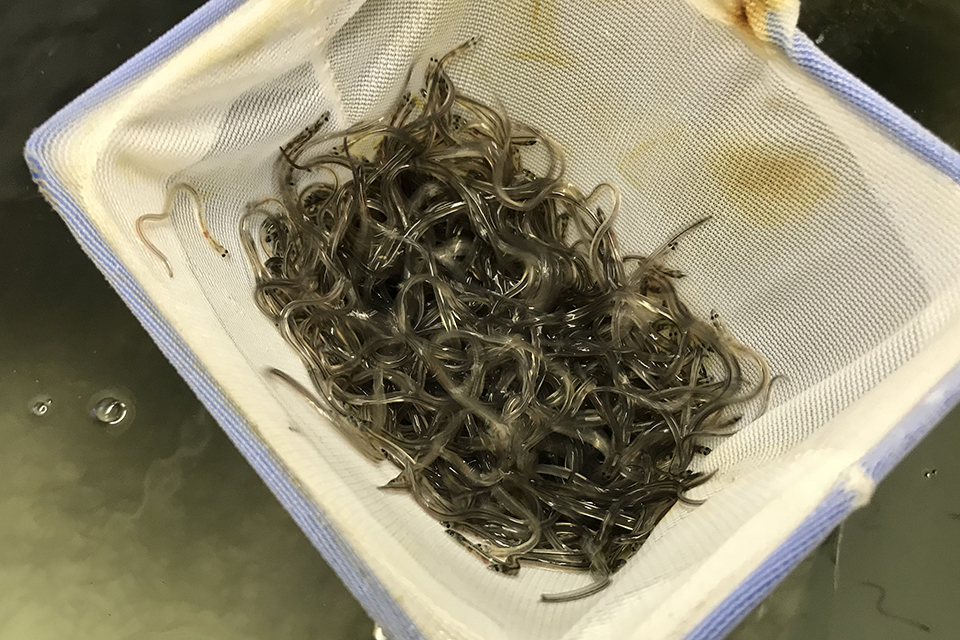

The recirculating aquaculture system (RAS) produces Pacific white shrimp (Litopenaeus vannamei), the most widely cultured shrimp species worldwide, and includes a hatchery established five years ago that has been producing and selling shrimp postlarvae to shrimp farmers in several countries around the world.

Homegrown also now boasts its newly finished indoor grow-out facility, which recently started operations.

“Homegrown Shrimp now creates in the U.S. a much-desired, premium, wholesome and sustainable shrimp that consumers can enjoy and also feel good about consuming it,” said Dr. Robins McIntosh, CEO and senior VP at Charoen Pokphand Foods (CP Foods), the Thailand-based parent company.

The Homegrown postlarvae are produced from genetically improved shrimp lines globally developed by CP Foods. The land-based company was established to showcase CP Foods’ shrimp-culture technology and its commitment to producing sustainable shrimp in those countries it trades and conducts business with.

The hatchery has the capacity to produce more than 60 million postlarvae annually, and its new 80,000-square-foot metal building to grow the postlarvae to market size includes 40 circular production tanks and eight tanks to recycle water and collect solid wastes, as well as a state-of-the-art water recirculation system. It has the ability to control and keep water temperatures – a critical limitation to the outdoor culture of shrimp – at slightly over 30 degrees-C, ideal for shrimp growth, survival and well-being.

CP Foods has been a leader in the development of shrimp culture since 1985, when less than 500 tons of shrimp was being produced worldwide. Today, that figure eclipses 5 million tons of shrimp – and much of that increase has been possible thanks to technologies developed within the CP Foods Group. Its pioneering advances in shrimp genetics and in culture system technologies have reduced the cost of shrimp to consumers, made more shrimp available to the huge U.S. market, and made shrimp the most-consumed seafood product in the country.

The opening ceremony included speeches from McIntosh as well as Thailand’s Ambassador to the United States, His Excellency Tanee Sangrat.

McIntosh’s final comments during the ceremony addressed the relevance of the innovative, industry-changing pioneering efforts embodied by the new company: “It is with disruptive technology being developed and optimized here that aquaculture becomes one of the solutions for our deteriorating oceans. Our mantra is ‘saving the oceans and helping feed people through aquaculture.’ Ultimately, as more knowledge is gained and efficiency improved in this facility, we envision these projects locally producing shrimp sustainably year-round anywhere in the world.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Darryl E. Jory, Ph.D.

Editor Emeritus

Global Seafood Alliance[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,121,114,111,106,46,108,121,114,114,97,100]

Tagged With

Related Posts

Intelligence

American Unagi breaks ground on land-based eel farm in Maine

Eel producer American Unagi has broken ground on a 27,000-square-foot recirculating aquaculture system near the coast of Maine.

Intelligence

Kingfish Maine harvests small batch of RAS Dutch yellowtail

Kingfish Maine released a limited run of Dutch yellowtail produced at a RAS facility in Maine, a precursor to its upcoming permanent site.

Intelligence

‘Away from the coast’: Latest Maine RAS venture chooses forest over seas

Land-based salmon farm Katahdin Salmon will be built far from the shoreline to where operational costs and conditions might lead to success sooner.

Intelligence

Full speed ahead for Florida pompano RAS farm

While many attempts to farm Florida pompano have fallen short, Joe Cardenas is undaunted, confident that recirculating aquaculture systems are the key.