TransparentSea Farm CEO Steve Sutton talks shrimp RAS with the Advocate and Aquademia

Greater Los Angeles is where very few aquaculture experts would advise starting a land-based shrimp farm. Too expensive. Too many regulations. Too much traffic (it is L.A. after all). But for Steve Sutton, it’s not only the perfect place to demonstrate proof of his urban aquaculture concept, it’s an ideal showcase for influencers who care about the environment but are passionate about great food.

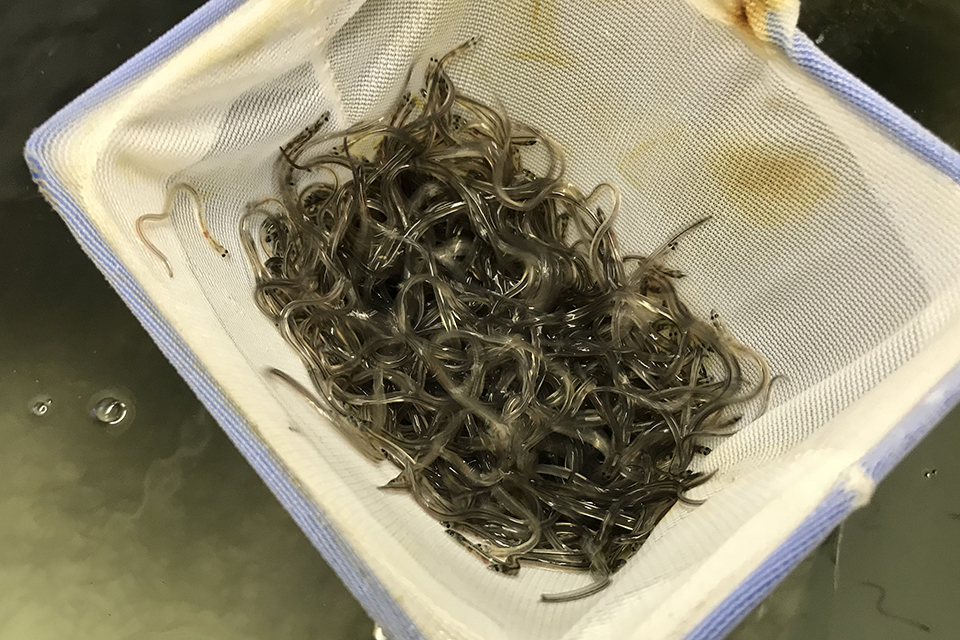

“We’re doing a lot of things that aren’t being done,” Sutton told the Advocate and the Aquademia podcast this week. (Editor’s Note: Sutton’s podcast appearance and this article were published simultaneously.) His young company, TransparentSea, which he admits is technically a “startup” but doesn’t do a lot of things that startups typically do, is harvesting Pacific white shrimp (Litopenaeus vannamei) grown in a recirculating aquaculture system that is housed in a once-derelict building, on a weekly basis now – and commanding strong prices in the process.

Sutton joined Advocate Editor James Wright and Aquademia Host and Producer Shaun O’Loughlin earlier this week for a conversation about urban aquaculture, influencing the influencers, carbon-capture technologies, seed stock procurement and of course, craft beer analogies.

Almost Hollywood

Southern California is not the most affordable place to start an aquaculture business, but the market for seafood there is strong and diverse. In a short time, however, TransparentSea has engaged with chefs who can drive demand for locally sourced food. And shrimp, Sutton reminded us, is still a versatile product and the No. 1 most-consumed seafood species in the U.S. market.

“When it comes to the reason I put [the farm] here … it’s just so diverse and the sheer volume of people within 30 miles, it’s like 15 million people plus visitors,” Sutton said. “You’ve got a really diverse group of people culturally, and shrimp or prawns are eaten worldwide.”

The start-in-L.A. reason might have been clear but finding an actual facility was anything but easy. Sutton originally had a deal to operate his farm in Long Beach, but it fell through once the pandemic hit. He then struggled to find a replacement but eventually discovered an old 1950s-era building that was once part of the space program – a site used to manufacture accessories for space capsules. It had seen better days.

“It was a junkyard of some absolute, ungodly, terrible state,” he said. “And I left with tears in my eyes on day one and I don’t generally cry, but I was like, ‘How am I gonna turn this into what it needs to be?’ And the answer was, one day at a time.”

He cleaned up the space and put in all brand-new equipment. Up to this point, the facility has succeeded in two ways: Firstly as a proof-of-concept for the recirculating aquaculture system (RAS) and secondly as a showroom. Sutton has been bringing in area chefs to witness the facility and see the locally grown shrimp for themselves.

“It has allowed me to get some of the best chefs in L.A. into this building. Once they see the process and they learn about aquaculture – half of the mission is already achieved. It has such utility in terms of getting attention,” he said. “If we put our first farm out in the middle of nowhere? I felt that we were gonna have to spend a lot more on marketing and have to hope that people care.”

TransparentSea Farm has hopes to expand into two commercial facilities in the near term – “somewhere in North America,” and likely in California, he said – the old building in Downey remains a strategic asset.

“We can train all our future employees here,” he said. “[They can] come here and they’ll work for anywhere from two weeks to six months before they move on to the next farm, or maybe they start their own in a joint venture. So having this as a teaching tool, as a demonstration tool, and as a self-sustaining business that makes more than it spends each month – we have no reason to shut it down.”

Cool but practical

Land-based aquaculture is not just a business model for Sutton: It’s an environmental play as well. Sutton said that shrimp farming globally needs to be removed from carbon-capturing mangrove forests so that the sensitive ecosystems can be replenished. RAS is the kind of planet-saving technology that investors should know about, he added, because of what it can do and the environmental impact it can prevent.

“It’s cool to have a startup to invent a robot that flies up in the air and harvests carbon. I mean, that’s all worthwhile and cool. But we have an answer looking at us straight in the face to just let the mangroves go back to being mangroves. And to use spaces that are non-virgin spaces like this one,” Sutton said. “And shrimp farming, I hate to say it, but it has a tangible, visible – you can use satellite imagery – it has left a mark. Through [RAS] technology, you can utilize 30 times less space than a really successful outdoor farm, maybe 100 times less space than an average or below-average farm.”

“But if the shrimp doesn’t taste good, arrive on time and be at a price that someone will pay for it, then none of it matters. That’s my daily struggle.”

Seedstock and biofloc

Another struggle is securing supplies of postlarvae to stock the farm for grow-out. Until the company establishes a hatchery, it will depend on seed stock suppliers. It’s a “volatile” element of the business that is out of the company’s control.

“We don’t have a hatchery. And that’s been kicking our butt,” he said, admitting that some investors are scared away by this and the high overhead costs. “We knew it was the No. 1 risk. I’m confident in my decision until the seed stock industry falls apart.”

“We do intermediate grow-out when we do have the seed stock available,” he continued. “So we hold them in a biofloc system. And they do really well at a young age and at a fairly low density. They grow great. Nothing wrong with a biofloc product. But we just feel that clear water gives us an element of control … I need to clear up the water. I need to be measuring as many things as possible and automate as many of those measurements.”

Pitching with confidence

With a laser focus on serving what local markets need, RAS facilities like TransparentSea Farm are well-positioned to meet evolving consumer needs and wants. And by serving fresh product with no preservatives, shrimp can start to shed the commodity label. Sutton agreed that his model bears similarities to that of a craft beer manufacturer. In what seems like a crowded space, there’s still plenty of room for artisan and large-scale producers alike.

“I’ve made dozens of investor decks at this point. And my first deck had exactly this comparison in it,” he said. “Like when Sam Adams started – they’re not really craft anymore by the scale, but they were.”

Even if the land-based shrimp farming sector – bringing a fresh or flash-frozen, high-quality, low-footprint prawn to the market at U.S. $15 a pound – could capture just 2 percent of the domestic market, that’s still a significant chunk, Sutton argued. “That would be something like $640 million. I then tell the investors, is that something worth pursuing?”

“We’re taking the approach now that we want investors to feel comfortable by saying, ‘Wow, you’ve done this on a relative shoestring budget. And you’ve had profitable months in the first, you know, 15 months of existence with all the problems that befall new facilities and with all of the staffing issues that have come up.’ We’ve been able to show that we’re at breakeven or better. Yeah, so I think we’re a startup, but … we’ll show how to intelligently scale and reduce risk as we scale.”

“We’ve hit the commercial density we want. We’ve shown that the market is hungry for this at a price that’s higher than I had in my original business plan,” he continued. “We’re looking at probably a 30 million dollar fund-raise. We can only go as fast as the funding and finding the land and getting the permitting done are possible. But simultaneously I’ve turned down dozens of offers to get engaged on a joint venture and share the technology because it’s ready – but it’s ready under our guidance.”

Listen to the full Aquademia episode here.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Seafood Alliance

Portsmouth, NH, USA[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,116,104,103,105,114,119,46,115,101,109,97,106]

Related Posts

Intelligence

American Unagi breaks ground on land-based eel farm in Maine

Eel producer American Unagi has broken ground on a 27,000-square-foot recirculating aquaculture system near the coast of Maine.

Innovation & Investment

A salmon farm in Dubai, because of course

Last year Dubai-based Fish Farm LLC sold the first batch of salmon to be born and bred in the United Arab Emirates. More are certainly coming.

Innovation & Investment

Robins McIntosh: Florida RAS shrimp farm the first of many

CP Foods’ Robins McIntosh is turning a 40-acre site in Florida into a next-generation shrimp farm, producing 1,000 tons annually with zero waste.

Intelligence

U.S. chefs, businesses and NGOs team up to launch the Coalition for Sustainable Aquaculture

TV star Andrew Zimmern is among a group of chefs who have teamed with leading environmental groups to advocate for responsible aquaculture.