Results show a negative effect of higher biofloc densities on dissolved oxygen levels and animal survival

The implementation of biofloc technology (BFT) has allowed an increase in shrimp culture stocking densities but at the cost of raising the requirements for dissolved oxygen (DO) in the water of production units. In these systems, in addition to the cultured shrimp, there is a range of other DO consumers, such as the added aquafeed and the microorganism community; the latter can vary significantly in density throughout the culture period.

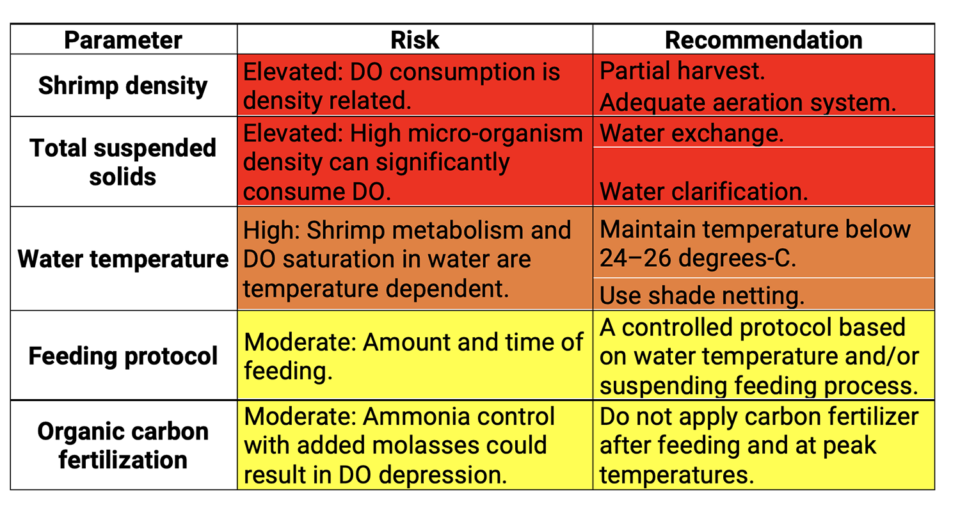

The high oxygen consumption in BFT systems depends on several factors such as density of cultured organisms like shrimp, total suspended solids (TSS) and water temperature. The microbial community in biofloc needs oxygen for the generation of new organic matter, using about 4 grams of oxygen for each 1 gram of ammonia that is converted to microbial biomass. Therefore, the biofloc community (measured as total suspended solids) can become a potential risk for the cultured animals in the absence of enough dissolved oxygen. Because BFT systems rely on technologies such as blowers and hydraulic pumps to generate and replenish oxygen in the culture water, the risk of energy outbreaks, generator or pump failures could lead to a potential drop in oxygen levels, with resulting mortalities in the cultured organisms.

The water temperature directly affects the metabolism of the aquacultured animal and the solubility of oxygen in its aqueous environment. In warmer waters, the animal metabolism increases while the oxygen solubility decreases. Under low levels of available dissolved oxygen, the animals re-direct all energy to basic activities start to protect themselves.

The re-establishment of oxygen or re-oxygenation that happens after the oxygen supply is removed causes stress and damage to the cultured shrimp and decreases their production rates, with resulting mortalities that can range from 10 to 90 percent and be seriously impact the shrimp farmer. In this article, we describe a recent study to examine the relationship between shrimp density, biofloc TSS and dissolved oxygen behavior in an experimental BFT system.

Study setup

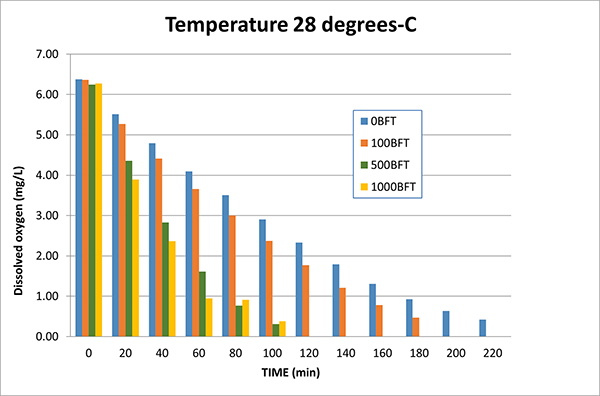

The study was carried out at the Shrimp Culture Laboratory, Institute of Oceanography, Federal University of Rio Grande in Brazil. TSS from a mature biofloc culture was concentrated and then diluted to reach the desired experimental concentrations for all the tanks. The tanks were placed in thermostatic, aerated (to prevent thermal stratification of the water) baths to maintain a water temperature of 28 degrees-C throughout the experiment.

Juvenile L. vannamei shrimp (individual weights around 12 grams) were stocked in 20-liter volume, plastic tanks with individual aeration supplies. The stocking density used was 450 shrimp per cubic meter and four different concentrations of TSS were tested – 0, 100, 500 and 1,000 mg per liter each with three replicates.

The trial involved two steps: First we checked the time of dissolved oxygen consumption to reach hypoxia [condition in which the body or a region of the body is deprived of adequate oxygen supply at the tissue level]. Then, we re-oxygenated the water and determined the time needed to reach the critical point for dissolved oxygen (DO ≤ 0.6 mg per liter). In addition, some water quality parameters (pH, nitrite and ammonia) were also measured in all treatments before starting the test.

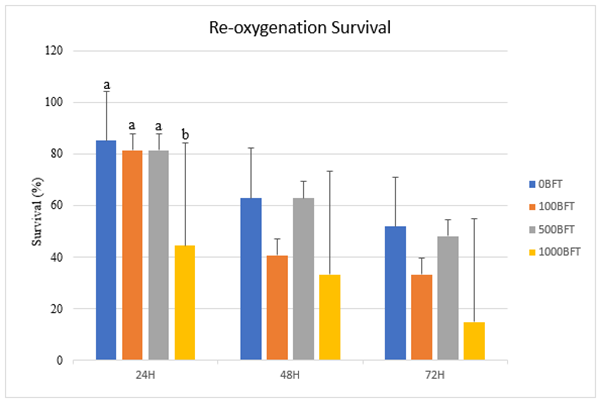

Dissolved oxygen levels were initially measured in all tanks, and then the air supply was cut off and again measured at 20-minute intervals until levels reached 0.6 mg per liter. Then, the aeration was turned on and the survival was monitored 24 hours, 48 hours and 72 hours after the aeration had resumed.

Results and discussion

The water temperature of 28 degrees-C (recommended temperature for the species) maintained throughout the experiment resulted in a significant increase in the metabolism of the shrimp, and consequently in their oxygen consumption, as was expected.

In the first step of the trial, the tanks with the highest TSS levels (500-1000 mg per liter) reached critical DO levels in a shorter period of time (200 percent faster than tanks with TSS levels of 100 mg per liter), reflecting the high DO consumption by the biofloc community.

In the second step of the trial, shrimp survival was significantly affected by the critical decrease in DO levels, with substantial differences observed during the first 24 hours, and with the lower survival in those treatment with the higher TSS levels (1000 mg per liter) having shrimp survival of less than 50 percent, and to between 20 and 40 percent after 48 hrs.

After 72 hours of recovery after OD levels had reached the critical point (<0.6 mg per liter), shrimp survivals for all TSS levels were no more than 50 percent. For the higher density treatments of shrimp and biofloc, animal survival was below 20 percent, showing that high levels of biofloc have a negative effect in recovery of shrimp after exposure to critical DO levels.

Conclusions

Based on our results, we recommend determining a strict protocol for dissolved oxygen management in shrimp biofloc culture systems. It is also critical to monitor and maintain adequate TSS concentrations, animal culture density, and water temperature. We also emphasize the importance of not letting dissolved oxygen levels go under the value of 2 mg per liter.

Our data and observations from both experiments showed that the density of the cultured animals and of the biofloc in the BFT system can directly influence the consumption of dissolved oxygen in the water, and consequently affect the production performance of the shrimp. In this regard, in Table 1 we have listed various DO risk parameters for shrimp cultured in BFT systems, along with pertinent management recommendations.

Finally, we recommend developing an emergency response protocol for aeration emergencies that considers and includes various commercially available equipment – such as electric gensets, alarms, oxygen cylinders and on-site generators, hydrogen peroxide and water exchange – to support a quick response (60 minutes) to any DO emergencies in BFT culture systems.

All references are available from the corresponding author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Marilia Costa, M.Sc.

Shrimp Culture Laboratory, Institute of Oceanography, Federal University of Rio Grande - FURG, C. P. 474, Rio Grande, RS CEP 96201-900, Brazil

-

Leonardo Oliveira

Shrimp Culture Laboratory, Institute of Oceanography, Federal University of Rio Grande - FURG, C. P. 474, Rio Grande, RS CEP 96201-900, Brazil

-

Lucelia Borges, Ph.D.

Shrimp Culture Laboratory, Institute of Oceanography, Federal University of Rio Grande - FURG, C. P. 474, Rio Grande, RS CEP 96201-900, Brazil

-

Victor Torres Rosas, Ph.D.

Corresponding author

Shrimp Culture Laboratory, Institute of Oceanography, Federal University of Rio Grande - FURG, C. P. 474, Rio Grande, RS CEP 96201-900, Brazil[109,111,99,46,108,105,97,109,116,111,104,64,57,114,116,99,105,118]

-

Wilson Wasielesky Junior, Ph.D.

Shrimp Culture Laboratory, Institute of Oceanography, Federal University of Rio Grande - FURG, Hotel Street, 02, Rio Grande, RS, Cassino CEP 96210-030, Brazil

Tagged With

Related Posts

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Health & Welfare

Nursery performance of Pacific white shrimp in zero-exchange biofloc systems

The authors conducted studies to test the performance of young shrimp postlarvae in systems with different approaches to aeration and water handling. Proactive management through proper feed applications and water quality control were critical elements.

Intelligence

We can grow better shrimp, and in better ways

The recent Central American Aquaculture Symposium in Choluteca, Honduras, brought together more than 600 participants to discuss industry issues and perspectives. The focus was shrimp diseases and their impacts on production, as well as practical alternatives to face these issues and move forward.