Performance of salmon-supporting technologies featured on day one of the world’s largest seafood business conference

Salmon aquaculture is big business in Norway, which exported nearly U.S. $6.6 billion of the fish in 2020, according to Kontali. Yet it is troubled by a small creature: sea lice.

Much of Norway’s aquaculture policy is influenced by the presence of sea lice (Lepeophtheirus salmonis). The Norwegian government and industry have invested billions of kroner to protect farms from sea lice and many of the latest and greatest solutions were on display during the opening day of the North Atlantic Seafood Forum, held in Bergen.

Sven Kolstø, CEO of OptoScale, started the day’s presentations with a metaphor about driving at night. A salmon farm site manager today has a continuous flow of information and data about their fish, including health diagnostics and lice counts. But very rarely will this person have “hard solid facts” about what’s happening with the fish and is therefore “blindfolded.”

With today’s “new paradigm of precise fish farming,” that site manager can go from “steering their car with a candlelight to turning on the flood beams,” said Kolstø. Using artificial intelligence-powered cameras that measure tens of thousands of fish every day can optimize feeding and bring clarity to health information. Trondheim-based OptoScale can detect injuries like winter wounds and give accurate, automatic sea lice counts.

“The precision train is leaving the station. We are seeing a large number of farmers ready to invest in precision data. Who will be on board? Have they spent enough time with the skills of their employees?” asked Kolstø.

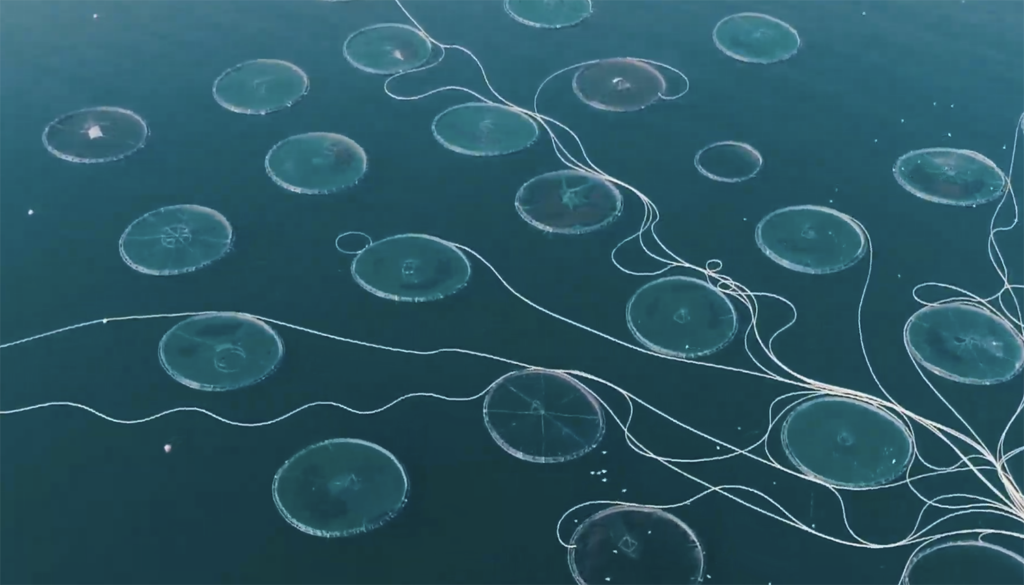

While digital technology and software are all the rage these days, plenty of attention is still given to hardware, like the material used in net pens out at sea. India-based company Garware has become one of the largest providers of net-pen materials and has become a pioneer in HDPE usage.

Vayu Garware, chairman and managing director of the family-based company with $500 million in annual revenue, said that more than 16,500 cages worldwide are using Garware products, and 267 cages in Norway are installed with V2 Yarn nets, which are infused with copper but allow no sedimentation, making it an environmentally friendly option. The copper ions delay biofouling, meaning V2 Yarn nets need far less maintenance, which drives down operational costs.

The nets’ value extends to fish escape prevention, predator management and sea lice mitigation. And the company’s latest product, IntelliNet, which is being trialed in Norway, Scotland and Chile, incorporates IoT (Internet of things) technology, so that any damage to the cage can be quickly detected for expedient repair.

“Our cages can speak to you,” said Garware.

Perhaps no sea lice prevention technology steps up to the level of the iFarm, a product of Norway-based Biosort, which has been developed in partnership with salmon producer Cermaq. The iFarm technology combines a submerged net “roof” that keeps fish below the critical sea lice “belt” that is approximately 10 meters below the surface. But the fish are able to swim to the surface to refill their swim bladders, and in the process, they are scanned for health issues like lice, injuries and even diseases. Each fish is identifiable via the dot patterns on their skin.

Biosort is now working on its second-generation sorter. According to CEO Geir Stang Hauge, the company soon hopes to have actual video footage of the compelling technology at work, as opposed to animated videos.

“[iFarm] will enable a health record for each fish in the cage and the ability to sort out fish for lice treatment,” he said.

Lastly, Kira Salonius, CEO of Norway-based biotechnology company Previwo, said that biological challenges (sea lice, disease) are now the number one cost to salmon farmers, surpassing feed. Biological costs have increased fivefold over the past decade, she added.

The company’s Stembiont™ product, now in its second generation, can strengthen skin health and increase growth by reducing the impact and mortality due to bacteria causing ulcers and parasites like sea lice. Essentially a “microbial re-enforcement bath,” Stembiont™ provides beneficial bacteria that are safe, easy to use, efficient through the entire seawater phase of the fish’s life and have been proven effective in trials on more than 12 million fish to date.

It’s a “de-risking tool” that can lower mortality by 36 percent and reduce the risk of severe ulcers by 73 percent.

“Respect the biology of the animals we’re growing,” urged Salonius.

Off-flavors, X-rays, SalmoFan and more

- Of course, there are no sea lice on land, so recirculating aquaculture systems (RAS) companies also have a lot to say about their offerings. Igal Magen, CTO of Biofishency, talked about the company’s ELX technology, which mitigates off-flavors caused by geosmin and MIB, common issues with RAS systems. The issue is more complex for cold-water farms, like those for Atlantic salmon and rainbow trout, for example. The efficiency of biofilters is lower, explained Magen. Physicochemical water treatment techniques that Biofishency provides purge off-flavors and users can analyze real-time data via a cloud-based dashboard that allows remote operation.

- Will X-rays become a common aspect of fish processing? Silvia Morar-Seyfi, head of business development at Denmark-based Innospexion thinks so. Removing pin bones from salmon fillets is typically a manual task that is hampered in many ways. Low temperatures can affect kinetic sense, and currently, processors use their own sense of touch to locate these tricky bones. Rubber glove usage and the overall tediousness of the task also contribute to lower success in detecting pin bones. But as Morar-Seyfi explained, X-ray machines developed by Innospexion can accurately and reliably detect bones based on a sophisticated algorithm that is not pattern-dependent, as pin bone distribution within a fillet is not uniform from fish to fish. Innospexion can detect bones down as thin as 0.35 mm in thickness. The company is now working with its first salmon producer and hopes it will build on the success that Portuguese company MareDeus experienced with this technology on cod fillets.

- The DSM SalmoFan™ has been around for 25 years, but it’s now digital. Fabio Cervellione, Director, Nutrition & Health Solutions Aqua Global at G.O. Johnsens AS, said the SalmoFan™ is now “accepted as the language of color” but with its new handheld scanner, the company can provide novel, accurate, specific and fast readings that help producers reduce downgrades and customer complaints about the color of their salmon fillets.

- France-based black soldier fly larvae farmer Innovasea provided an update about the growth of insect-based feed ingredients. Chief Business Officer Nizar El Alami said the “world is going to go through a protein wall,” and the aquafeed industry needs more tools to address potential shortcomings. Black soldier fly larvae meal is a “complete and balanced protein, with high digestibility and high lauric acid content,” said El Alami, who added that a new plant in Decatur, Ill., USA, will be able to produce 60,000 metric tons (MT) by 2028.

- Fish welfare is presently an important topic for all aquaculture producers and good practices go beyond health strategies, said Børre Haanes Waagan with MMC First Process, which offers a “gentle” fish handling system for RAS producers. The company can transport fish via a pump that does not harm the fish or cause them stress. This “new mindset for moving fish,” Haanes Waagan said, improves welfare but also aids growth rates and overall product quality.

- Because many salmon net pens employ sea lice “skirts” that prevent sea lice from entering the pens at their preferred shallow depth, the water flow is impacted and lowers the oxygen levels. So even ocean-based systems can benefit from aeration, said John Arve Kleppe, director of business development at Innovasjø Akvakultur. Promising another precision aquaculture solution, the company’s aquaControl technology helps to optimize production, improve fish health and protect fish stocks from algal blooms. “Observe, interpret, decide, act” is the AI-empowered workflow, and maintaining proper oxygen levels aids fish health and improves feed conversion ratios.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Seafood Alliance

Portsmouth, NH, USA

james.wright@globalseafood.org

Related Posts

Innovation & Investment

Bergen becoming seafood startup city as accelerator Hatch sets up shop

Hatch Aquaculture Accelerator aims to support new companies, via an immersive three-month mentorship program, in the health, nutrition, technology and production sectors.

Innovation & Investment

Apps, AI and algae: Meet Hatch Blue’s fourth cohort

Hatch Blue’s fourth cohort performed their pitches online for the first time, showcasing a spectrum of aquaculture product and service businesses.

Innovation & Investment

Farmers deploy new high-tech tools against sea lice

Salmon farmers in Norway are trialing two new technologies, including one from Silicon Valley, in their ongoing battle with the persistent sea lice.

Intelligence

Notes from the 15th North Atlantic Seafood Forum

C-level seafood executives from around the world gathered at the North Atlantic Seafood Forum to discuss pressing issues facing fisheries and aquaculture.