Sweden-based startup’s land-based shrimp farming model is powered by low-grade waste heat and produces a supplemental feed

Land-based aquaculture has lengthy lists of both pros and cons. Farming seafood on land can greatly reduce potential harm caused to fragile ocean and freshwater ecosystems; it can also be costly to build and power a facility. It offers next-level control and biosecurity measures; even a small technical breakdown can lead to a catastrophic failure – an entire crop of fish can be lost in moments.

A Swedish startup is rethinking the land-based aquaculture model with technology that not only solves the energy conundrum but also partially addresses another major cost center for aquaculture: feeds. Cresponix, a company founded in Stockholm, Sweden, in 2020 is an aquaculture-category finalist for the Global Seafood Alliance’s Responsible Seafood Innovation Award.

The technology Cresponix has developed and piloted in warm climates is, in the words of their founders, really a waste treatment technology that recycles farmed fish waste. It feeds it to a consortium of microbes that, when fermented, produces an edible and nutritious single-cell biomass that can supplement traditional aquafeeds and reduce feed costs by 30 to 40 percent. They’re now ready to try it in colder climates like they have at home.

But make no mistake – this is not your typical recirculating aquaculture system (or RAS). The three company co-founders told the Advocate that the Cresponix concept, what they have dubbed “Bio-RAS,” or biologically-based RAS, bears similarities to aquaponics, in which multiple products – in this case shrimp and tilapia – are raised, with the water from one helping to improve living conditions for the other. Common RAS as the industry knows it today is expensive, dependent on external water purification facilities and does nothing to make feed use more efficient.

“[Cresponix is] a RAS with bioflocs, but in several compartments, so it’s a different concept completely,” explained co-founder Sergio Zimmermann, who has decades of experience in water management and was a consultant to Brazilian shrimp producer Camanor in 2015 when it won the Innovation Award. “I would say that the main difference towards other farming technologies is that we are more sophisticated and evolved around zero effluent and ‘on farm’ feed production.”

Whereas RAS is a linear system, with mechanical filters and waste coming out of the end of the system, the Cresponix system is circular. It pumps its wastewater into several “microbial communities” where bacteria and algae grow off the waste. The bacteria and algae protein can be fermented and recycled back as feed to the shrimp growing in the system.

Not only nutrition but good fish welfare is also baked into the system, Zimmermann added.

“The fermentation process that happens aerobically and anaerobically in our system complements the nutrition of the animal. Their immune system is boosted, and you see in shrimp and tilapia that survival is higher – 25 to 40 percent. So, with this technology we bring better nutrition and welfare,” he said.

Co-founder Anders Kiessling helped develop the technology at the Swedish University of Agriculture, where he is a professor. He said that the system has been successfully implemented on 16 large-scale Bio-RAS fish farms in South America, which are all still in operation, with the largest producing 5,000 metric tons (MT) of shrimp annually.

“We put in exactly as much as we take out of the system and everything else is circulated like in a small ecosystem,” he explained. Cresponix aquaculture systems only need to be located where they can take advantage of industrial waste heat, such as near hydrogen power plants, steel plants, pulp mills, data centers and so forth.

“We are in a temperature sector that’s extremely interested in finding new recycling technologies for low-grade waste heat,” he said. “The Cresponix system is very beneficial to be placed downstream from developing green industry, it is a solution to produce locally and sustainable food from an energy source that otherwise would not be utilized. It has enormous potential for colder climates and production systems not dependent on arable land or water resources but can be located very close to [communities].”

Cresponix could produce nearly any type of fish, especially those with omnivorous feeding habits, but the company sees Pacific white shrimp (L. vannamei) as the most suitable species right now. The European market for shrimp, said CEO Mattias Djurstedt, is steady and relies heavily on imports.

“[Shrimp] is shipped around the world, but there’s a lot happening in the shrimp sector now in the USA, Japan, China and Europe,” said Djurstedt, who said the company plans to build a facility in Sweden as soon as next year and then license the technology down the road. “There’s a race to be the first commercially verified technology to produce [shrimp] in temperate climates, but nobody’s really done that yet. The trend is that production cost is more and more important, and the initial cost of establishing things in the food sector becomes secondary.”

It has enormous potential for colder climates and production systems not dependent on arable land or water resources.

Djurstedt said the Cresponix mission fits into his main goal in life, which is to “feed the world without destroying it.” After determining that aquaculture was the surest path to achieving this goal, he set out to build an “A team” and quickly found Zimmermann and Kiessling.

“Google fish farming in Sweden and Anders immediately comes up,” said Djurstedt, who once studied under Kiessling. “I think I built up some kind of trust capital, and we started the business together. I appreciate very much their joining me on this journey because they have so much opportunity to do so many other things.”

Cresponix aims to build a large-scale pilot facility (5 MT capacity) in Våstervik, Sweden, next year, with eyes on a 200-MT capacity farm the following year. By 2028, they hope to be selling the technology throughout Scandinavia.

“Everything is possible,” said Zimmermann, “it’s just a matter of engineering.”

GSA’s Responsible Seafood Innovation Awards – sponsored by the U.S. Soybean Export Council – for the aquaculture and fisheries categories will be awarded at the Responsible Seafood Summit in Saint John, N.B., Canada, on October 3, 2023. The winner will be decided by an audience poll.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Seafood Alliance

Portsmouth, NH, USA[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,116,104,103,105,114,119,46,115,101,109,97,106]

Tagged With

Related Posts

Innovation & Investment

‘Choices are limited when searching for alternatives to antibiotics’: How one veterinarian is employing bacteriophages to fight Vibriosis in shrimp farming

GOAL 2022: Bacteriophages can overcome antibiotics in aquaculture's fight against Vibriosis in shrimp farming, and Dr. C.R. Subhashini is leading that fight.

Health & Welfare

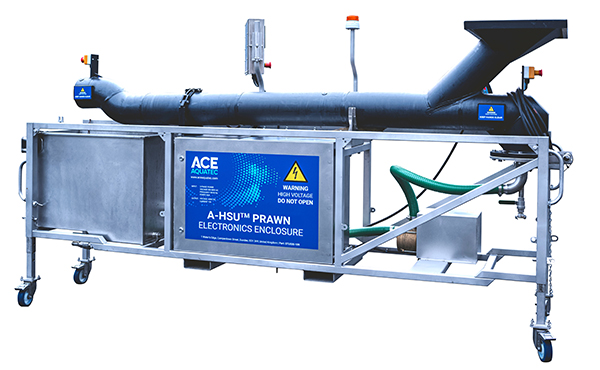

Ace Aquatec launches in-water portable prawn stunner to improve aquaculture welfare

The company's Prawn Humane Stunner Universal can stun prawns unconscious in less than one second, improving animal welfare in aquaculture.

Fisheries

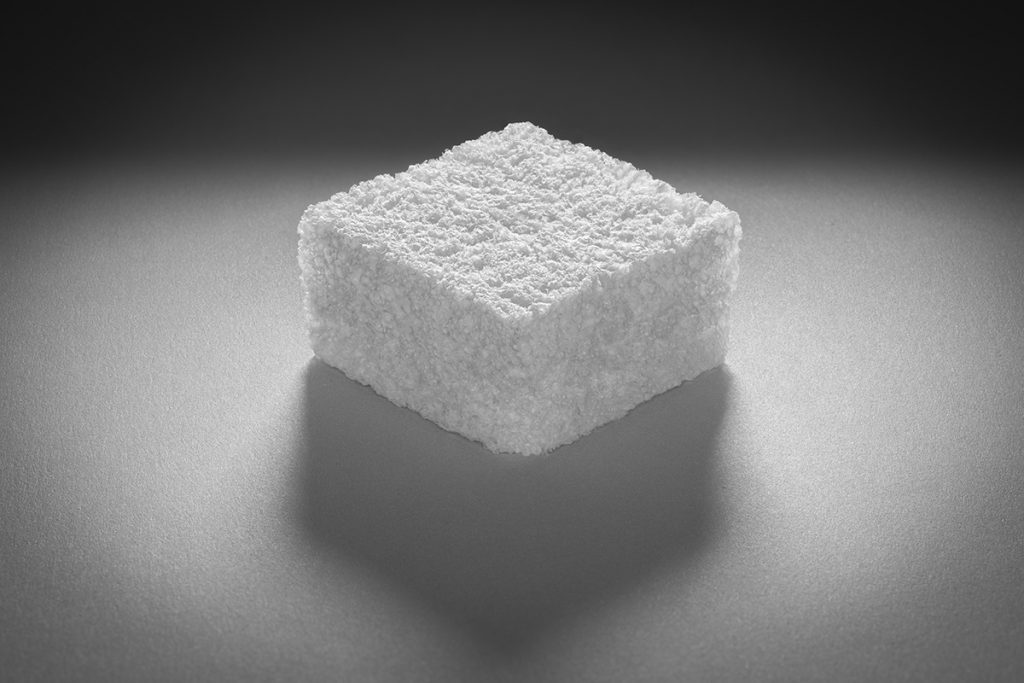

‘Regulation is pushing toward greenifying materials’: How one innovator is upcycling seafood waste into biodegradable packaging foam

GOAL 22: Cruz Foam’s biodegradable packaging foam made with shrimp shells is a finalist for GSA’s inaugural Global Fisheries Innovation Award.

Innovation & Investment

Aquafeed ingredient AlgaPrime wins GAA Innovation Award

A proliferation of alternative feed ingredients has allowed aquaculture to extend the natural resources it depends on. AlgaPrime, packed with the long-chain omega-3 fatty acid DHA, is being recognized as a game-changing innovation for aquaculture feeds.