Plant-based fish vaccines could provide low-cost, high safety and effective protection for farmed fish species

The high fish densities used in the farming of many fish species increase the risks of outbreaks of a variety of aquatic diseases. Fish vaccines have been highly effective and safe in protecting fish from diseases with minimal ecological impact and being applicable to all species of farmed fishes. Vaccination is the mainstream technology for fish disease prophylaxis worldwide, and the normative production standard for international modern aquaculture.

Since the 1980s, the development of fish vaccines has made significant progress. The number of commercial vaccines available for use in fish expanded from two in the 1980s to about 34 currently. Up to the year 2020, over 140 fish vaccines had received approval globally, according to incomplete statistics.

Vaccine types mainly include live vaccines, inactivated vaccines, and genetically engineered vaccines. Recombinant subunit vaccines [which contain only purified parts of the pathogen, not the whole pathogen] – one kind of genetically engineered vaccines, which elicit a protective immune response – represent promising options for high safety, high stability, easy production, easy control, and good immunogenicity [the ability of a foreign substance to provoke an immune response in the body].

Subunit antigens [any substance that causes the immune system to produce antibodies against it, because the immune system does not recognize the substance and is trying to combat it] have been produced in bacteria, yeast, transgenic plants, insects, mammalian cell cultures, and cell-free platforms.

This article – adapted and summarized from the original publication (Su, Hang et al. 2021. Plant-Produced Vaccines: Future Applications in Aquaculture. Frontiers in Plant Science, 12 Aug 2021, 12:718775) – summarizes the development status of fish vaccines and describes the potential of plant biotechnological engineering for their further development.

Development of fish vaccines

Fish vaccines are normally classified into three types based on preparation methods; these are live vaccines, inactivated vaccines and genetically engineered vaccines. Live vaccines are prepared with pathogens managed by attenuation or mutated attenuation [produced by reducing the virulence of a pathogen but keeping it viable, or “live”]. Inactivated vaccines are inactivated pathogenic microorganisms that remain immunogenic [retaining the ability to provoke an immune response]. They have the ability to induce specific resistance in aquatic animals after inoculation. For genetically engineered vaccines, different types include recombinant subunit vaccines, DNA vaccines, gene deletion/mutant vaccines and live-vector vaccines. The most widely applied fish vaccines currently are inactivated and live attenuated vaccines.

Delivery methods for fish vaccines include injection, immersion and oral administration. Intramuscular or intraperitoneal injection is the most popular method, providing an exact vaccination dosage and regulating systemic immune responses, but can cause fish stress responses and is time-consuming, laborious and relatively expensive. For immersion, the mechanism of fish vaccination during immersion immunization is still uncertain. However, vaccine concentration, immersion time, aquatic animal size, antigen forms, water temperature and others are factors affecting the uptake of the immune antigens by the hosts.

Since aquatic animals live in an environment inseparable from water and are cultured in large bodies of water, many consider oral immunization to be the most ideal vaccination method for fish and other aquacultured animals. Oral vaccination provides a non-stressful and energy-saving administration for both fish and farmers. However, oral vaccination procedures are difficult to standardize. The large surface area of the intestine increases the possibility of antigen breakdown in the gastrointestinal tract, leading to mostly local mucosal immune responses and immune tolerance. Vaccination dosage, vaccination regime, antigen formulation, encapsulation, species and other factors must be considered for oral administration; further research is needed to achieve a balance between immune responses and tolerance.

Each kind of vaccine has its own advantages and shortcomings, and the choice of vaccine and delivery method is largely dependent on characteristics of the farmed fish species, such as size, feeding habits, culture temperature and economic value. Pathogens and protection required also need to be considered. The economic cost is another essential factor for aquaculture industries, mostly related to the value of farmed fish.

Future fish vaccines against infectious pathogens – including viruses, bacteria, fungi and parasites – in modern aquaculture industries should be cost-effective and environmentally friendly. They should allow for large-scale production and also be available and suitable for small fish farmers. Application of plant biotechnological techniques in fish vaccine development could satisfy these requirements for fish vaccination.

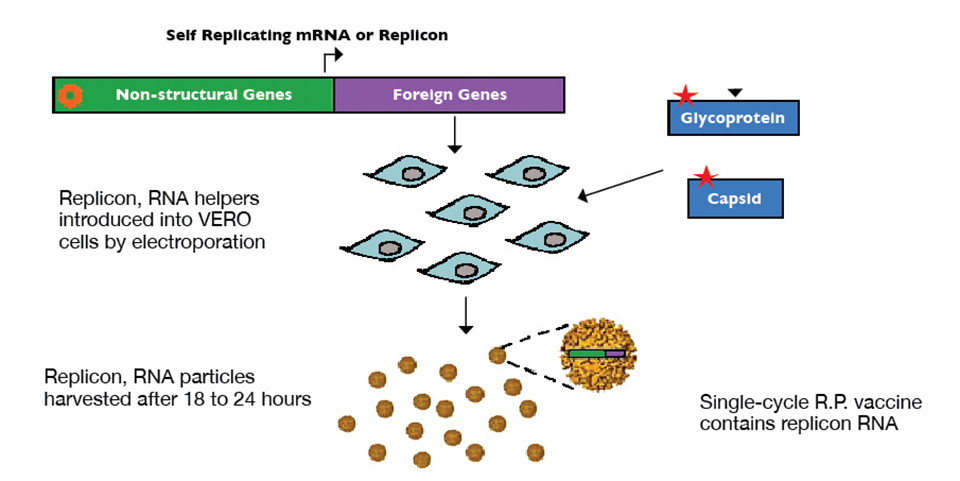

Alphavirus replicon particles potential method for WSSV vaccination of white shrimp

Plant-based vaccine development and application

Many pre-clinical and clinical studies of plant-made human and animal recombinant pharmaceutical proteins have proved the feasibility, efficacy and safety of plant factories for vaccines, and a plant-based platform offers attractive advantages for recombinant subunit vaccines.

One advantage is that it is an environmentally friendly vaccine production platform using free solar energy and capturing carbon dioxide (CO2), with low energy requirements and no greenhouse gas emissions, reducing the cost of vaccines. Another advantage is that plant-based systems can be used to produce vaccines for oral delivery which do not require sophisticated bioreactors and complex downstream processing, thereby becoming a more economical system than the conventional expression systems. Hence, scaling-up of production is safe, cheaper and the scale is not restricted by the size and number of available bioreactors.

Plant-made vaccines do not have the safety concerns of live vaccines. Moreover, undesirable or toxic components, such as bacterial toxins and undesirable proteins from yeast, have not been found in plant-derived systems, in contrast to mammalian-based production systems. Plant-based systems also possess a high capacity for biosynthesis, similar to naturally occurring systems, increasing vaccine immunogenicity. Plant-based platforms do have some disadvantages in still uncertain efficiency, quantity and quality of recombinant proteins and dosage of vaccines in tissues.

Various species of plants are available for plant molecular farming. Genome engineering of edible plants has been utilized to produce many kinds of foreign proteins in lettuce, tomato, potato, cabbage and other plants. Transgenic plants have been used to produce vaccines against viruses, bacteria and parasites. Vaccine production in algae is another system used for transient expression and there are also many examples of algal-produced biopharmaceuticals.

Microalgae offer health-promoting benefits as nutritional supplements in aquafeeds for their digestibility, high contents of proteins, lipids, essential nutrients and potential immunogenicity. Microalgae can be a viable protein production and oral delivery system to vaccinate fish. Genetic engineering technologies in microalgae offer the possibility of producing “functional feed additives” with no need for complex post-production conditions, such as purification, cold chain and injection. Various microalgae have been processed to express antigen genes for the prevention and control of infectious diseases. Although several species of microalgae have been widely used in the aquaculture industry, many of them have not yet become established as an effective and mature genetic manipulation system.

Plant-based vaccines are ideal for oral administration. The manufacturing process is simple and there is no additional medical device needed for injection. Plant-based vaccines with high purity make vaccination more convenient and induce stronger immune responses. Vaccine antigens ingested by oral administration go through the gastric environment and are absorbed in the intestine, inducing immune responses.

Potential for plant-made vaccines

For new fish vaccines, the economic cost is one of the most important factors due to the nature of aquaculture with high farming cluster density and large scale. Plants provide a production platform for vaccines with high cost-effectiveness, efficiency and safety. Despite having a higher monetary cost than antibiotics, plant-based vaccine production systems are still a cost-effective and promising approach offering efficient and safe vaccines to protect fish health and manage the sustainable development of the fast-growing aquaculture industry globally.

Diversity of fish species, type of fish diseases, characteristics of the vaccine target, timeline, scaling-up potential, resources, biosafety concerns, future commercial perspective, feeding habits of fish and management difficulty also need to be considered prior to selection of a plant expression system for fish vaccine production.

The number of studies into the use of plants for the production of subunit vaccines for fish is still small but growing. Fish vaccines made in edible plants offer great potential for oral vaccination in aquaculture. A plant-generated recombinant subunit vaccine could also provide several antigen proteins simultaneously. Oral vaccines produced in edible crops offer unique cost advantages and antigen stability at room temperature. And oral vaccination provides for a non-stressful and energy-saving administration of vaccines for both fish and farmers. However, no plant-produced fish vaccine has been commercialized to date and further research is needed.

Plant expression systems [for the production of recombinant proteins to bring together genetic material from multiple sources, creating sequences that would not otherwise be found in the genome and without contaminating animal proteins, toxins or pathogens] are a great option for the production of virus-like particles, VLPs [multiprotein structures that mimic the organization and conformation of authentic native viruses but lack the viral genome, potentially yielding safer and cheaper vaccine candidates]. A handful of approved, prophylactic VLP-based vaccines are currently commercialized worldwide for several human diseases. Plant-made VLP vaccines are promising for fish viral diseases and their potential use in the near future.

Perspectives

Health management of aquacultured animals is important because of globally increasing food and food safety demands. Plant-based fish vaccines could provide low-cost, high safety and effective protection for farmed fish species. However, the development of plant-made fish vaccines is still lagging behind efforts to produce plant-made vaccines for use in humans and non-aquatic animals.

Our review summarized the status of fish vaccine management and the application of plant genetic engineering in fish vaccine production. Plant-made recombinant protein vaccines using oral administration show special advantages for production and vaccination. However, plant-made vaccines have not yet been approved for oral delivery.

Research on plant-based vaccines focuses mostly on increasing the amount and purity of antigen in transgenic plants to stimulate adequate immune responses. Targeting the most suitable subcellular compartment in plant cells is also of great importance for the optimal quantity and quality of antigens.

At this time, the production and application of plant-made vaccines still face several challenges, yet the promise and potential of better plant-based vaccines are attractive. Plant-based is an emerging type of vaccine and plant biotechnology provides a perfect option for production and vaccination. More research should be carried out to meet this urgent need, and we anticipate that regulatory approval will be granted eventually.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Hang Su, Ph.D.

Division of Biotechnology and Plant Health, NIBIO - Norwegian Institute of Bioeconomy Research, Ås, Norway; and

Department of Aquatic Animal Medicine, College of Fisheries, Huazhong Agricultural University, Wuhan, China -

Igor A. Yakovlev, Ph.D.

Division of Biotechnology and Plant Health, NIBIO - Norwegian Institute of Bioeconomy Research, Ås, Norway

-

André van Eerde, Ph.D.

Division of Biotechnology and Plant Health, NIBIO - Norwegian Institute of Bioeconomy Research, Ås, Norway

-

Jianguo Su, Ph.D.

Department of Aquatic Animal Medicine, College of Fisheries, Huazhong Agricultural University, Wuhan, China

-

Jihong Liu Clarke, Ph.D.

Corresponding author

Division of Biotechnology and Plant Health, NIBIO - Norwegian Institute of Bioeconomy Research, Ås, Norway[111,110,46,111,105,98,105,110,64,101,107,114,97,108,99,45,117,105,108,46,103,110,111,104,105,106]

Related Posts

Health & Welfare

Alphavirus replicon particles potential method for WSSV vaccination of white shrimp

A study demonstrated that VP19 and VP28 white spot syndrome virus envelope proteins expressed by replicon particles provided protection against mortality due to WSSV in shrimp.

Health & Welfare

Israeli firms developing oral medicines for shrimp and finfish aquaculture

Israeli companies ViAqua Therapeutics and TransAlgae say their orally administered medicines for shrimp and fish aquaculture are in the pipeline.

Innovation & Investment

Global Aquaculture Innovation Award finalist: VakSea

An orally administered vaccine product holds great promise for aquaculture, and Maryland-based startup VakSea is on the cusp of providing one. Sensing a major opportunity, the company’s focus has pivoted to shrimp.

Health & Welfare

Oral vaccine delivery effective in reducing salmon diseases

Oral vaccination can be done with virtually all fish sizes and is a relatively stress-free and inexpensive approach. The authors developed a novel oral vaccine delivery system that was found effective against infectious salmon anemia and salmonid rickettsial septicemia at salmon farms in Chile.