With dried kelp making up 90% of the market, kelp dryer shows promise for helping seaweed farming companies to expand

With more U.S. seaweed farms coming online on both the Atlantic and Pacific coasts, producers’ concerns are shifting from raw material procurement to processing. With well-established preferences for seaweed products in the marketplace, it behooves local producers to meet them to wean the market off of imports.

When Mitchell Lench, CEO of Oceans Balance in Biddeford, Maine, discovered an industrial kelp dryer that could dry up to 3 million pounds of farmed seaweed annually was available in South Africa, he jumped at the opportunity to purchase the $650,000 machine and ship it across the sea.

Oceans Balance had been blanching and freezing its farmed kelp for years because there wasn’t a suitable dehydrator available. It was limiting their business options.

“The kelp harvest always comes in at the same time of year, March through May, and you can’t dry it outside if you’re in a cold climate, so we had to freeze it,” he said. “But frozen kelp has a limited market. Ninety percent of the [global kelp] market is dried kelp.”

The company had tried drying in greenhouses and using other dehydrating machines designed for wild kelp, but the temperatures were too high for farmed kelp. Lench needed a machine that could handle 10,000 pounds of kelp biomass per day. When it arrived in May, his prayers were answered.

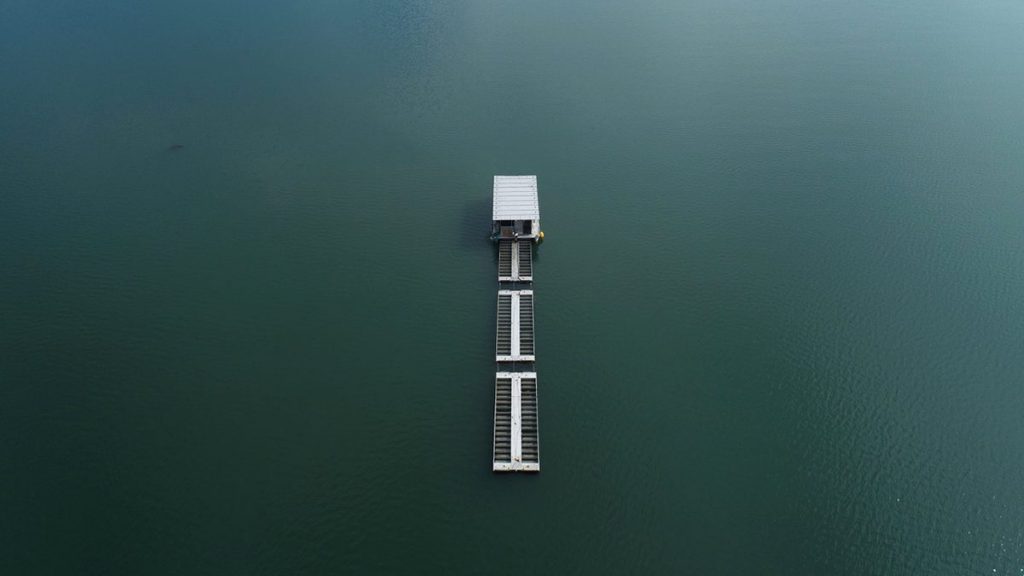

The 50-foot-long, 17-ton machine uses belts to dry the seaweed at low temperatures, which preserves its nutritional properties. The seaweed is shred and spread evenly on the belts for drying, and the dehydrator can be operated by one or two people, so its labor requirements are minimal.

Exploring the relevancy, resiliency and scalability of seaweed farming at Seagriculture

Since its capacity is three times more than Oceans Balance requires, Lench formed a new company, Seaweed Farmer Services, offering dehydration and kelp milling to other kelp farmers as well as to agricultural producers in Maine.

“If you can dehydrate seaweed, which is very sticky, then you can dehydrate almost anything through this machine, so we think this will be of interest to agricultural producers. But in the meantime, we’re getting calls daily from kelp farmers in British Columbia, Alaska and Norway who have run into the same issue and who are interested in using our dehydrator,” he said.

“All the reports on the seaweed market point to the same problem: the issue with drying or dehydrating. And everyone wants to farm more seaweed, but there’s only so much frozen seaweed that the market is demanding.”

The new dehydrator is a game-changer, he added, one that will allow Oceans Balance and its competitors to compete more effectively in the global market for seaweed. Moreover, it will allow Oceans Balance to discontinue its frozen farmed kelp and to dehydrate other high-value wild kelp species in the future, including dulce and nori.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Vancouver-based correspondent Lauren Kramer has written about the seafood industry for nearly 20 years.

Tagged With

Related Posts

Responsibility

Can ranching ‘zombie urchins’ boost uni, save kelp forests?

With Norwegian knowledge and a partnership with Mitsubishi, Urchinomics aims to turn worthless empty urchins into valuable seafood while restoring kelp forests and creating jobs.

Innovation & Investment

Canadian ‘climate action’ company to test its green gravel for kelp forest restoration

Cascadia Seaweed, a British Columbia-based climate-action company, will test its kelp forest-restoration technology this summer off the coast of Nova Scotia.

Responsibility

Can kelp farming fix the planet? Experts weigh in on promises and pitfalls

How can kelp farming help solve global challenges? A panel of seaweed experts discussed promises, pitfalls and knowledge gaps.

Innovation & Investment

This Maine company thinks kelp buoys and oyster farming can save the ocean through carbon capture and sequestration

Maine-based Running Tide uses carbon-capture and oyster farming techniques – using both low and high technology – to restore ocean health.