Prof. Boyd discusses the underground injection of wastewater and its applicability to aquaculture

Wastewater from municipalities, food processing, manufacturing and aquaculture production facilities typically are discharged into surface water bodies – usually following treatment to lessen pollution concentrations and loads. Wastewater also can be injected underground as a final means of disposal in some locations where underground geology allows it to be done safely. A special well is designed and constructed and the wastewater is injected by way of this well into a formation of gravel, sand, sandstone or limestone situated between upper and lower formations of impervious geological material.

Underground injection of wastewater often is confused with the use of liquids in hydraulic fracturing (popularly called fracking) in the gas and oil industry. However, in fracking, the liquid is introduced under high pressure to create small fractures within tightly compressed shale formations to enhance crude oil and natural gas extraction. In underground injection of wastewater, the water is under much less pressure, and it is introduced into porous formations or saline water aquifers not useful for water supply.

Deep-well injection has been practiced for almost a century for the disposal of saline water from oil and gas fields and salt-mining operations. More recently, it has been used for disposal of industrial and municipal wastewater and even radioactive wastes.

Shallow-well injection also can be used to dispose of wastewater. In some cases, a well may not be necessary. A basin can be constructed to hold the water and allow it to infiltrate downward into the shallow aquifer below. In areas where aquifers have been drawn down through withdrawal by wells, shallow-well injection of treated municipal wastewater has been used as an aquifer recharge method.

Design and construction

The well itself must be properly designed and constructed. For deep-well injection, a borehole is drilled from the land surface into the formation for disposal. The borehole is fitted with an outer casing (pipe) and a second, smaller-diameter casing is extended inside the outer casing. The annulus between the outer and middle casings is filled with cement grout. The injection tube (pipe) is extended inside the middle casing. The annulus between the injection tube and the middle casing is filled with a non-corrosive fluid and pressurized to a greater pressure than the pressure applied to wastewater being injected to prevent leaks from the injection tube. The injection tube extends beyond the lower and of the outer and middle casings and a tight seal is installed where the injection tube extends beyond the casings.

Shallow-injection wells may be similar to deep-injection wells in design. Shallow underground disposal of wastewater is also accomplished with storm runoff ponds, agricultural drainage wells, infiltration ponds, septic system infiltration fields and other relatively simple methods of encouraging downward infiltration.

Many of the early attempts at underground injection of wastewater via crudely designed injection wells created serious cases of salinization. Water pollution and health risks can obviously result from underground disposal of wastewater done improperly. However, geological methods for evaluation of the suitability of proposed sites for underground disposal of wastewater and injection well design have greatly improved, and the technology does not create unacceptable environmental risks when applied properly.

Water injected underground may seep into other aquifers that are used for water supply, and it may seep into streams where their bottoms cut below the elevation of the water table. In coastal areas, formations may outcrop into the seabed and wastewater may enter the sea. However, by proper site selection, underground injection can be confined to places where it is unlikely that hydraulic connections exist between the formations receiving the wastewater and aquifers used for water supply. Moreover, while fracking can cause small earthquakes, there have been few reported incidents of underground wastewater injection causing earth tremors.

Some may wonder where the injected wastewater goes. It enters the pore spaces in formations and compresses the gases in these pores ahead of it. The pressure deforms rocks within the formations creating more pore space, and uplifting may occur to make space for the injected water. When injected into an aquifer, wastewater will increase the saturated depth of an unconfined aquifer, increase pressure in a confined aquifer and increase aquifer discharge through base flow into streams or the sea.

The feasibility of underground injection depends primarily on the geologic environment beneath the disposal site. A suitable situation consists of a permeable injection zone to receive the wastewater, impermeable rock layers above and below the formation that receives the injected wastewater and a sequence of rock units between the upper layer confining the waste and the freshwater aquifer above (where such exists).

Regulations

The United States Environmental Protection Agency has developed rules by which permits for both deep-well and shallow-well injection projects can be granted. Several other countries do likewise, and the practice has become rather common. The Best Aquaculture Practices Hatchery Standard has an option for shallow-well injection into saline aquifers. In addition, BAP is considering an option for deep-well injection of effluent from water recirculating aquaculture systems.

Perspectives

Aquaculture wastewaters have comparatively low concentrations of nutrients and organic matter and they do not contain toxins and pathogens of human health concern. Their disposal carries a much lower pollution risk than does the dispersal of municipal and industrial wastewaters.

The greatest risk about underground injection in aquaculture probably relates to high salinity in effluents from facilities that culture brackish water or marine species. Particular attention would be necessary to assure that underground injection of salty water from hatcheries or production facilities would not enter aquifers useful for freshwater supply.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Professor Emeritus

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University, Auburn, AL 36849[117,100,101,46,110,114,117,98,117,97,64,49,101,99,100,121,111,98]

Related Posts

Innovation & Investment

20,000 lettuces under the sea: Could underwater agriculture be the future of farming?

Preliminary research suggests that emerging mariculture methods could provide alternatives to land-based agriculture and within recirculating systems.

Responsibility

Can Salicornia effectively treat aquaculture effluent?

Trial demonstrates that artificial wetlands of Salicornia neei can be used for wastewater treatment in saline aquaculture in South America.

Responsibility

Composting of seafood processing sludge

Study evaluates if controlling maturation stage during seafood sludge composting through turning improves the process in comparison to static composting.

Responsibility

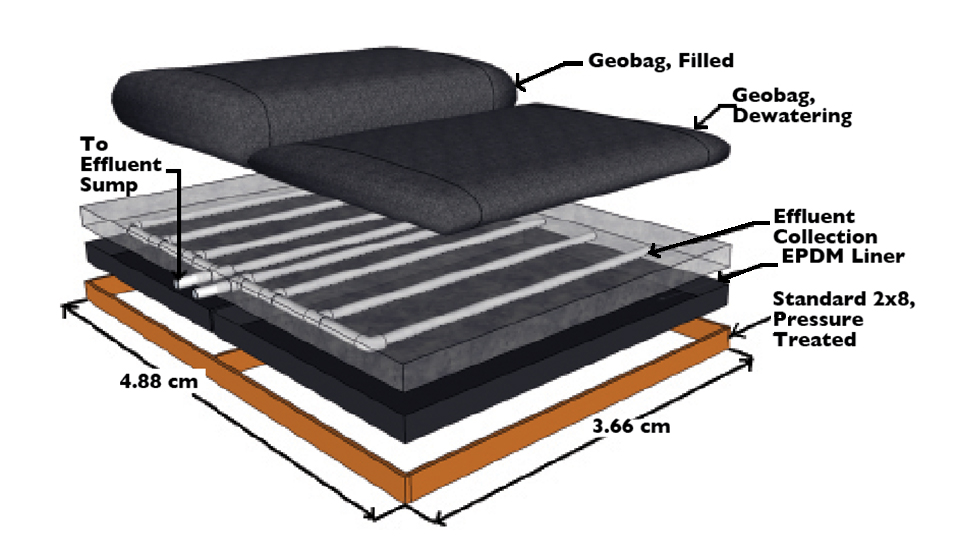

Geotextile bags enhance effluent management in demo aquaculture system

One promising new technology for dewatering aquaculture solid waste is the use of geotextile bags: porous, sealed tubular containers constructed of high-strength, woven polyethylene material.