Improved identification, assessment of safety risk factors ensures the safety of aquatic products

According to the Food and Agriculture Organization of the United Nations (FAO), the production of global fisheries and aquaculture reached 214 million metric tons, and the amount for human consumption reached 20.2 kg per capita in 2020. Aquatic products are playing an increasingly important role in providing food sources and nutrition, including in ensuring global food security in the future. It is well known that the processing and storage methods used affect the quality and safety of aquatic products, which are important issues for scientists, consumers and the industry as a whole.

This article – adapted and summarized from the original publication (Pan, C. et al. 2022. Aquatic Products’ Quality, Processing and Preserving: Recent Developments, Trends and Advances. Appl. Sci. 2022, 12(24), 12924) – discusses research and development of new processing and preservation technologies, investigations of quality change phenomena and their mechanisms, the application of new quality evaluation methods as well as the establishment of risk assessment and control technologies for aquatic products to ensure the supply of high-quality and safe aquatic products.

Protein structures of aquatic products

Unlike mammals, aquatic products are derived from cold-blooded animals. Their protein structures are relatively soft so that they can perform physiological functions in different environments. This makes the storage of aquatic products are more difficult than livestock and poultry meat because they need to be carried out under lower temperature conditions to obtain a longer shelf life.

Undesirable changes such as protein denaturation, lipid oxidation, the growth of ice crystals and loss of texture properties can still occur in aquatic products during low-temperature storage. These phenomena negatively affect the products’ quality and consumer acceptability. Moreover, in industrial production, contamination by microorganisms also plays an important role in food quality and shelf life. With the extension of storage time, nutrients of food are used as substrates for some psychrophile growth and reproduction, and the resulting metabolites seriously threaten food safety.

There are some disadvantages of protein-based conventional food analysis: (1) when using highly processed and low-protein aquatic products, the analysis may yield false/negative results; (2) the content of the same protein can show different expression levels in different tissues in aquatic animals, which affects determination using traditional methods; and (3) there are many other substances in aquatic animals other than protein, such as lipids, polysaccharides, phenols, and others, and the changes in quality are also correlated with these substances, which cannot be determined by traditional protein-based methods.

Furthermore, metabolomics [the scientific study of chemical processes involving metabolites, the small molecule substrates, intermediates, and products of cell metabolism] is another systematic analysis method which illustrate the species, quantity and change regulation of metabolites in a given biological system. There have been related studies on aquatic products that mainly focused on environmental challenges and potential quality biomarkers.

Quality control procedures

Aquatic product producers are increasingly demanding effective quality control procedures to meet and regulate consumer demands, improving processing feasibility and quality. In addition, chemical and microbiological changes during processing and storage can affect food quality and shelf life. Therefore, understanding the impact of each preservation technique and handling method on the production system is essential in food processing to maintain food quality and ensure its safety.

However, traditional analytical safety and quality monitoring methods take time and require well-trained operators, so there is a need to develop fast, sensitive and reliable methods to rapidly monitor aquatic products’ safety and quality.

Biosensors

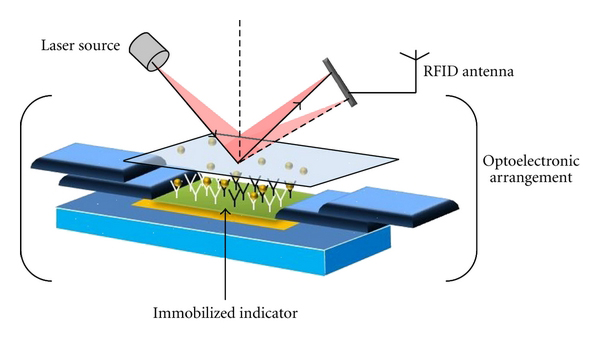

Biosensors [analytical devices used for the detection of a chemical substance, that combines a biological component with a physicochemical detector] can be a suitable alternative to traditional methods. Biosensor devices are the most appropriate diagnostic methods for food analysis and environmental and clinical inspections. This is because they are specific, fast, easy to manufacture and economically applicable.

The specificity of these devices is achieved by bioconjugation reactions involving antigens or antibodies, enzymes, cofactors/substrates, ligands/receptors, nucleic acid hybridization and chemical reactions in combination with many sensors. Biosensors are combinatorial receptor transducer systems that provide discriminatory semi-quantitative or quantitative analytical descriptions via biometric recognition units. Miniature biosensors can be incorporated into packaging materials and combined with wireless tracking technologies to generate tracking information about the production system and the supply chain. In addition, biosensors are manufactured for various types of analytes related to food safety.

To improve food quality, these biosensors detect contaminants such as metal ions, gases, vapors, biomolecules, organic molecules and foodborne micro-organisms. Most conventional methods take about a week to produce results when identifying foodborne pathogens, while biosensors can yield results in just a few hours.

In recent years, there have also been some reports of biosensors in the detection of stress response and disease resistance in aquatic animals such as fish. Through these biosensors, producers can better control the source and the process of aquatic products to improve product quality and safety.

Perspectives

The development and implementation of novel aquatic product quality evaluation methods with the advantages of being fast, accurate and non-destructive will be a prerequisite for ensuring the quality and safety of aquatic products.

The in-depth investigation of molecular mechanisms of aquatic product quality changes based on foodomics [discipline that studies the domains of food and nutrition through the application and integration of advanced -omics technologies to improve consumer’s well-being, health, and knowledge; it requires the combination of food chemistry, biological sciences, and data analysis] can provide a theoretical basis for the development of novel methods and technologies for aquatic products processing and preserving.

In addition, the identification and assessment of new food safety risk factors will be an important aspect to ensure the safety of aquatic products. In the future, research on the quality, processing and storage of aquatic products will also focus on these aspects.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Dr. Yongqiang Zhao

Corresponding author

Key Laboratory of Aquatic Product Processing, Ministry of Agriculture and Rural, South China Sea Fisheries Research Institute, Chinese Academy of Fishery Sciences, Guangzhou 510300, China[110,99,46,99,97,46,105,114,102,115,99,115,64,113,121,111,97,104,122]

Tagged With

Related Posts

Responsibility

‘They thought we were crazy’: Behind one Faroe Island salmon farmer’s bold stance to reduce its carbon emissions

Hiddenfjord executive’s insistence that “fish should never fly” flies in the face of industry norm. This Faroe Island salmon company intends to do things greener.

Innovation & Investment

American Unagi brings eel farming back ‘home’

Sara Rademaker launched American Unagi to shift eel farming to American soil, where the eels are from. Why? Because of the novelty, and because she saw an opportunity to do things better.

Health & Welfare

Dietary organic acids improve gut health, disease resistance in olive flounder

A study evaluated the effects of two organic acid blends on performance, gut health and disease resistance in olive flounder. The dietary organic acids were effective in lowering total gut bacterial counts, gut Vibrio counts and in conferring resistance against Edwardsiella tarda.

Health & Welfare

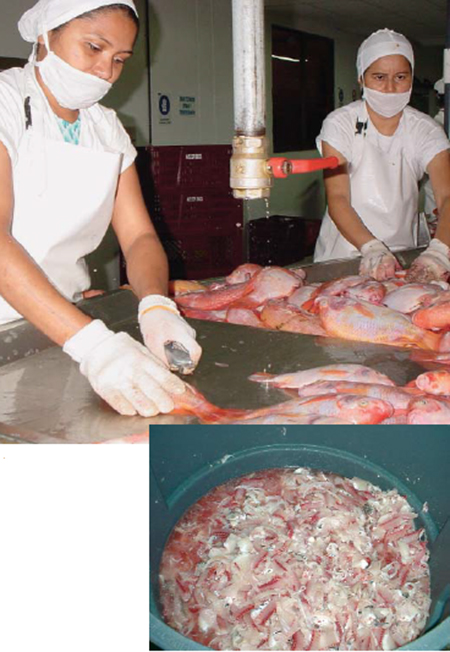

Fish silage: Bioconverted waste yields useful byproducts

Although its final quality can be variable, fish silage can be an effective protein supplement in feeds for various fish, shellfish and terrestrial animals.