What you need to know when weighing the purchase of a manual or automated fish skinner

Have you been tasked with researching and purchasing a fish skinner? Do you know what to look for when buying one? The sheer number of processing equipment options available can be overwhelming and leave you confused about how to find the fish-skinning solution best suited for your business. Here are some expert guidelines to help navigate your purchasing journey.

Always start with your product

When considering skinning units, always begin by looking at your own product, particularly in its final form. The following questions are the most important among processing machinery manufacturers:

- What fish species do you process?

- What is the weight of your average fish (or fillet)?

- What is your daily production capacity?

Answer these three questions and start identifying the true contenders.

What fish species do you process?

This question is important to answer because different fish species can require unique skinner settings. Most manufacturers work with a mechanical roller and a knife. These rollers and knives need to be dead-on precise to remove the skin, which is paper thin most of the time. The toughness of the skin and the flexibility of the fillet are major factors. (Pro tip: A STEEN specialist can set you up with the right roller-knife setting.)

What is the weight of your average fish or fish fillet?

This question is crucial in determining whether you need a soft-handling top unit for your skinner. A top unit’s main function is to guide the product during the skinning process. This component will eventually be pressing down on your fillet. When you have large fish, a little bit of pressure on your fillet won’t get the job done.

The bigger your fillets are, the harder they need to be pressed down by the top unit; if your pressure application is too soft, it won’t skin your product properly. Conversely, smaller fillets will require a lesser amount of pressure – if you apply too much, you will end up losing a lot of good meat and be left with a damaged fillet. No one wants that!

What is your daily capacity?

Here is the critical moment where you decide whether you will need an automatic skinner or a manual skinner. An automatic will skin a lot more fish in one minute compared to a manual one. But the manual skinner is three-to-five times less expensive than an automatic one. Let the experts in processing machinery advise you. Check out the STEEN website for more information.

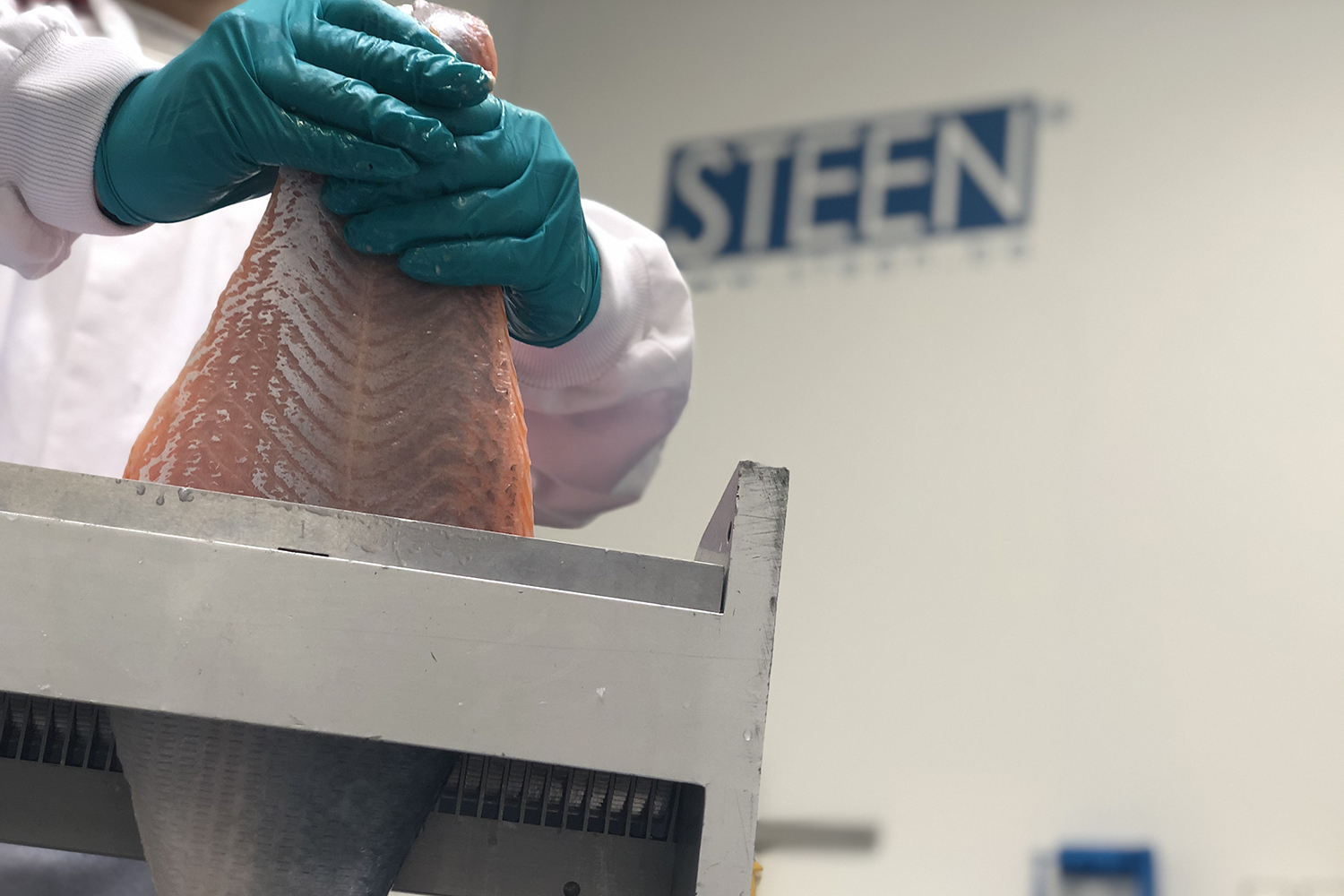

The manual fish skinner

With a manual skinner, the operator places the fish on the machine, presses a foot switch, and the machine removes the skin. There are no conveyor belts or other automations – just one machine and you, its operator.

Manual skinners are best suited for smaller operations like local fishmongers, fish restaurant operators and market vendors. Essentially, this kind machine is perfect for those in the fish industry who work by the order. A manual skinner can be placed on a working counter or be set up as a free-standing machine on wheels, which can be rolled about easily.

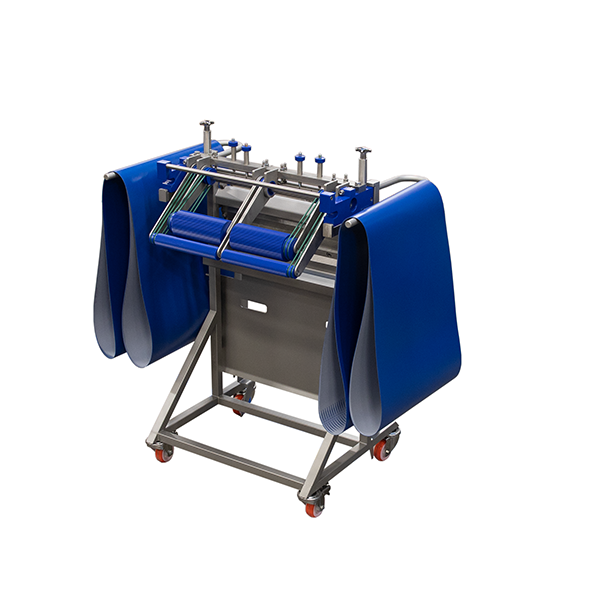

The automatic fish skinner

An automatic skinner is a machine that typically has conveyor belts and can be sometimes placed in line with your other processing machinery. (Pro tip: Before planning to do so, always contact your expert first.)

Automatic skinners are specialized pieces of equipment that can cope with a high-output capacity, are usually easy to operate and don’t need much maintenance when used correctly. Some automatic skinners have different options to skin, clean and maintain.

Here are some things you should look for when considering the purchase of an automatic skinner:

Do I want to regular skin or deep skin? Or both?

Regular skinning means you will only take off the skin and leave everything else – membrane and fat, for instance – on the meat.

Deep skinning is when you remove skin from the fillet along with some substantial fat as well. Species like salmon or tilapia have these fat structures, and some fish processors like to see the fat come off.

It is best practice to buy a machine that can do both regular and deep skinning. A lot of manufacturers can produce machines like this, but nobody quite like STEEN. See for yourself.

Does my machine need to be cleaned before I start processing?

If you’ve ever posed the above question to yourself, you’re right on the money. Yes, your machine needs to be cleaned and sanitized before and after you start processing. After all, you’re handling food and the consequences can be high if you don’t thoroughly clean your production equipment. What you should look for is a machine that is easy to clean and sanitize and is designed to limit bacterial build-up.

Here are some traits of an easy-clean machine:

- You can dismantle the machine in such a way that you can easily reach all angles with your hose

- You don’t need any tools to dismantle the machine

- You aren’t taking longer than two minutes to clean it

Machines like the STEEN ST700V possess all of these characteristics.

Author

-

STEEN

Established in 1960, STEEN is a Belgium-based company serving the food-processing sector, part of the F.P.M. International NV portfolio.

[101,98,46,110,101,101,116,115,64,103,110,105,115,101,101,115,46,122,110,101,114,117,97,108]