A handful of U.S. aquaculture hopefuls relish their (small) roles in the blue revolution

At its height, Dairyland Shrimp produced between 200 to 400 pounds of shrimp per month, supplying restaurants near the farm’s home base of Westby, a small agricultural town located roughly 30 miles east of La Crosse, Wisconsin, USA. It’s the American heartland, where fresh shrimp is a foreign concept.

That’s precisely why Dairyland’s founder, Forbes Adam, was drawn to the possibility of growing the popular seafood on his own after reading about an indoor shrimp farm in Iowa.

“I live in a very rural area and a lot of people in this area, let alone all of Wisconsin, don’t know what fresh shrimp tastes like,” he said. “They buy it from a grocery store and it’s from China, South America or India.”

So Adam self-financed his own operation to see if he could achieve enough success to entice investors. But they never came, something that Adam and other growers say is a major barrier to moving indoor shrimp farming forward in a meaningful way in America.

“Getting funds together from investors has been very difficult,” he said. “There are people who would like to do it, but it takes a lot of money.”

Indoor shrimp farming is one of those sectors where, based on a small sample size, there is an incongruity between the desire to fill a need and the ability to do so. Investment, high start-up costs and disease management pose difficulties for small farms aiming to grow. Some have found the obstacles too steep to overcome.

“I tried hard to increase production rates and it actually backfired because I overstocked the tanks,” Adam said. “By doing that, I overpopulated the tanks and I was going backwards and the shrimp started to die.”

Dairyland was forced to shut down operations earlier this year after growing Pacific white shrimp since 2013.

“We quit raising shrimp because we found it wasn’t profitable,” Adam said. “It cost too much to raise the shrimp indoors, considering the quantity of production. It was cost-prohibitive.”

Not for profit

“Well, after six months of not posting anything I figure I owe everyone an explanation,” read a Jan. 6 post on the Indiana-based Big Barn Shrimp Farm Facebook page. “We have fought and fought the survival rate in the shrimp business for two and a half years and it has won every time. So with that thought in mind, we will be starting a transition to raising tilapia in the coming year.” In August, Big Barn announced on that same page that the farm was instead closing its doors for good.

In the same year that Dairyland and Big Barn Shrimp Farm folded, another farm in the Midwest, Inland Shrimp Company, began while an established one on the East Coast, Marvesta Shrimp Farm, relocated from Hurlock, Maryland, to Charlotte, N.C. In their brief existences, both operations have experienced their own unique challenges within the industry.

With the first loan, that should put us at 12,000 to 14,000 pounds per year, a drop in the bucket compared to the domestic shrimp market. But that’s enough to launch us into the top 10 in the country for domestic producers.

Three years ago, Inland’s president and co-founder, Gary Beatty, found himself as a semifinalist at Fish 2.0, a business competition held at Stanford University in Palo Alto, Calif. The event intends to connect aquaculture and fishing businesses with investors. “I thought, after that, funding would have been fairly easy to come by because of the publicity and what people thought of the idea,” Beatty said.

Like Dairyland, Inland attracted no investors. “That’s really the biggest challenge,” Beatty said. “It really got to the point where I couldn’t obtain funding through angel investors or venture capitalists and small business administration loans wouldn’t work. So I really ended up bootstrapping just to get the prototype.”

For Beatty, Inland has been a 15-year odyssey that started off as a concept and only became a reality this year. With a degree in forestry and wildlife from the University of Cincinnati and a background in real estate, he became drawn to aquaculture because he felt it filled a need. “What propelled me was I saw a great opportunity to be in a fledgling industry where I thought we really can make a difference,” he said.

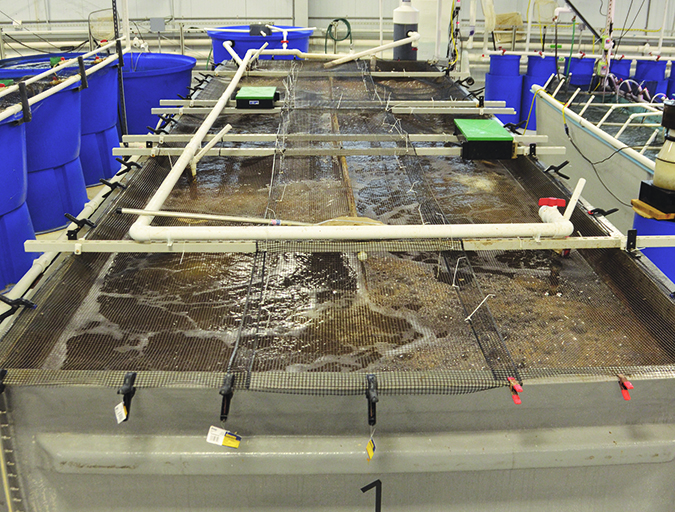

At present, Beatty’s operation is purposefully small; this summer he was growing shrimp out of his garage, estimating that his initial batch would harvest 25 to 30 pounds. His goal is to show viability in the hopes of securing a Farm Service Agency microloan to cover the cost of capital expansion.

“With the first loan, that should put us at 12,000 to 14,000 pounds per year, which is still a drop in the bucket compared to the domestic shrimp market,” he said. “But that’s enough to launch us into the top 10 in the country for domestic producers.”

The majority of the costs needed to make that happen, he said, are for the equipment – filtration and holding tanks – necessary to grow the shrimp. Beatty has big dreams because he understands that America is relying heavily on shrimp grown in other countries.

By growing shrimp locally, he said, cities like the one he lives in will benefit.

“Not only will we take a vacant warehouse, which are really numerous around every metropolitan area, and put a shrimp farm in it, which will stop urban blight, but we’ll create local jobs, reduce the carbon footprint and reduce shipping and transportation costs,” he said. “It will also reduce food waste because if shrimp is not sold today, it will be kept alive until tomorrow.”

As Inland Shrimp is just starting out, Marvesta Shrimp Farms is in a position of essentially starting over. Founded in 2003, the company experienced success, producing as much as 50,000 pounds of shrimp per year at its height before disease struck in 2013.

“We don’t know how it happened and it shouldn’t have been the kind of thing that got into the system,” said the company’s founder and president, Guy Furman. “At the end of the day, it was definitely devastating to see populations completely crash. It was a real major blow and almost made me quit the industry.”

Instead, Furman opted to bring production down to Charlotte, where an opportunity arose to grow shrimp less expensively inside a 32,000-square-foot facility that will eventually have the capacity to produce up to 10 tons of shrimp per year. Production has yet to commence, but when it does, Furman said the crustaceans will be sold to the company’s previous customers, which consisted of restaurants in Maryland and Washington, D.C.

High demand for shrimp

With over 1 billion pounds of shrimp consumed in the United States per year, Furman realizes there is a strong market. “Almost none of that is grown here or produced here,” he said, as Marvesta looks to reverse that trend as it regains its niche in the industry.

As for the current state of indoor shrimp farming, he said, “I think there are dozens of smaller operations up and running right now. At the same time, a lot of large-scale commercial operations that were well-funded have come and gone.”

One of those smaller operations can be found in a former elementary school in Ridgeway, Iowa, that was purchased by husband-and-wife team Jeff and Sherill Ryan roughly two and a half years ago. The building, which had been owned by the town and laid dormant for several years, allowed the Ryans to pass the biggest hurdle of shrimp farming – finding a fitting facility.

“When we decided to do this, we realized it was very expensive to put up a new building. We had the property to do it, but building it would cost about $500,000 before we got any equipment in it,” Sherill Ryan said. “We realized this building was available. We called up, asked if they were interested in selling it and took a look at it. We got it for a good deal.”

They are really interesting animals and something I didn’t know anything about before so the fascination is still there.

Jeff, who was once a student in the building where shrimp are now grown, is the creative genius behind the company’s name, Sherlock Shrimp. “It’s named after Sherlock Holmes who used to say, ‘It’s elementary, my dear Watson,’” explained Sherill Ryan.

Sherill oversees much of the operation as her husband farms full-time, while occasionally assisting with marketing efforts. With a previous career as a nurse and a background in the sciences, she made the professional shift after she became “obsessed with shrimping.”

Admittedly, it has not been easy as there are very few resources for start-ups like theirs. They are trying to change that by creating a cooperative for indoor shrimp farmers “where we are more organized and can make better decisions for aquaculture,” she said, “whether it’s providing education, finding ways to improve our marketing or determining the best type of feed for the shrimp.”

The business, which opened in June 2015, produces roughly 500 pounds of shrimp every two weeks that is sold to restaurants, caterers, walk-ins and health food co-ops within a 50-mile radius of Ridgeway.

“I like the biology and chemistry portion of it,” Sherill said, before adding, “I guess I like all of it really. It is just fascinating. They are really interesting animals and something I didn’t know anything about before so the fascination is still there.”

Author

-

Christopher Kazarian

Chris Kazarian is a freelance writer living on Cape Cod. His work has appeared in a variety of national and regional publications including Boston Herald, Providence Journal, The Hockey News, espnW, Cape Cod Magazine and Cape Cod Travel Guide.

Tagged With

Related Posts

Innovation & Investment

Thinking outside the cage: Avant-garde aquaculture in Norway

Salmon farming in Norway is poised for an innovation boom. The biggest players are putting cutting technology in the water to solve some of the industry’s most persistent problems, such as sea lice, fish escape and waste management.

Innovation & Investment

Eye in the sky: Europe employs satellites to advance aquaculture

Copernicus – the European Space Agency’s €4.3 billion Earth Observation System – holds potential benefits for fisheries and aquaculture. The SAFI project is approaching the aquaculture sector about harnessing, and montetizing, this unique service from up above.

Health & Welfare

Aquamimicry: A revolutionary concept for shrimp farming

Aquamimicry simulates natural, estuarine production conditions by creating zooplankton blooms as supplemental nutrition to the cultured shrimp, and beneficial bacteria to maintain water quality. Better-quality shrimp can be produced at lower cost and in a more sustainable manner.

Intelligence

Indoor-raised shrimp find potential market in Kentucky test

By raising shrimp in a closed building, producers can increase biosecurity, produce shrimp more consistently, grow shrimp year-round and locate production centers near markets. Chefs and consumers were very accepting of whole fresh shrimp, offered at a farmers market, that was farmed indoors in Kentucky.