New report offers snapshot into the energy requirements for the aquaculture sector

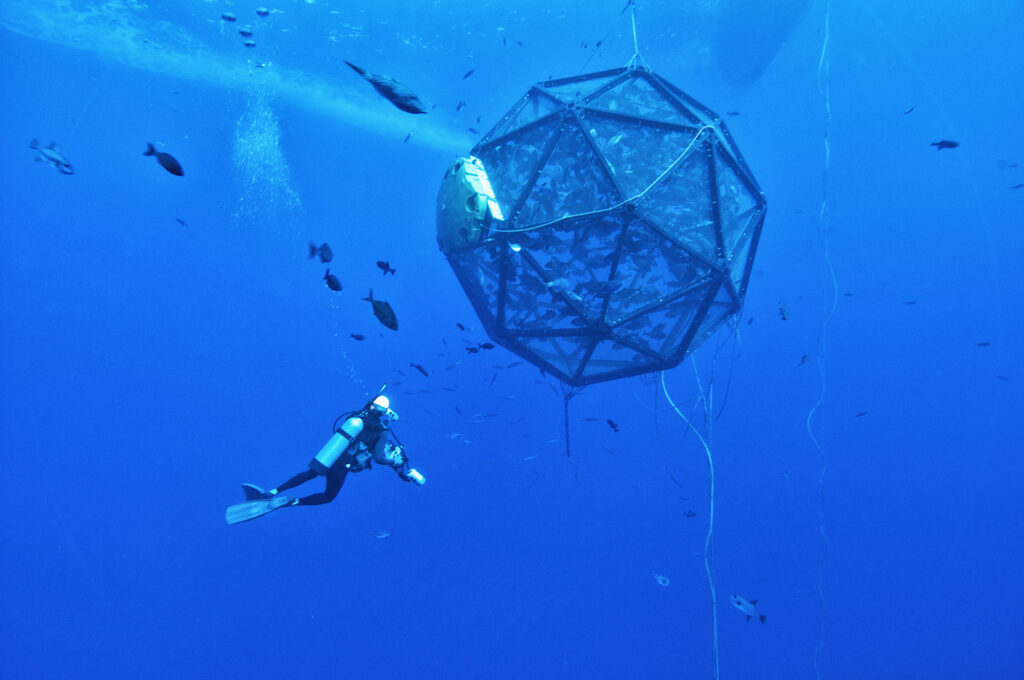

Ocean renewable energy (ORE) and offshore aquaculture are “likely compatible for co-location,” according to a new report commissioned by Ocean Energy Systems (OES) – an intergovernmental collaboration that operates under a framework established by the International Energy Agency (IEA) in Paris.

ORE covers all forms of energy derived directly from the seas and oceans, such as wave, tidal, ocean current, ocean thermal energy conversion and more. The 84-page report, Offshore Aquaculture as a Market for Ocean Renewable Energy, provides a comprehensive review of ORE technologies and their application for offshore aquaculture.

“Recently, the ORE industry has begun to look at alternative markets,” said Mikaela Freeman, co-author and a marine science and policy analyst at PNNL. “Aquaculture is a growing industry, and due to several factors, it’s starting to move offshore and look at that as a prospect. This presents a potential opportunity for ORE to pair with aquaculture and provide power. It also provides opportunities for sustainable marine development through co-location of activities.”

Prepared by the Pacific Northwest National Laboratory (PNNL), the Blue Economy Cooperative Research Centre (Blue Economy CRC), the Commonwealth Scientific and Industrial Research Organization (CSIRO), and OceanPixel Pte. Ltd, the research team investigated energy demands from aquaculture operations around the world, as well as considered the feasibility of co-locating offshore aquaculture with ORE as part of the blue economy. As defined in the report, “co-location” involves both the sharing of marine space between aquaculture and ORE, as well as ORE providing power to aquaculture operations.

“Aquaculture projects that are being developed have begun to include renewable energy technologies (ORE as well as solar photovoltaic and offshore wind energy) in their designs and planning,” wrote the authors. “The synergistic opportunities for co-located aquaculture and renewable energy can provide a multifunctional use of space and resources, creating opportunities to automate operations for safety and sustainability.”

The interest in moving operations offshore is expanding, fueled by a growing aquaculture industry and increased competition for marine-use space. According to the findings, ORE has the potential to power offshore aquaculture and can decrease the environmental impact of operations by providing power at sea and replacing the reliance on diesel.

“Given the increasing need to derive food from the oceans through aquaculture, and the evidence for this new human activity to be as carbon-free as possible, the potential for direct use of ocean energy for this sector had to be assessed very carefully,” said Yann-Hervé De Roeck, OES Chairman. “This report sheds a very useful and inspiring insight into this issue.”

Smart solutions are needed

As detailed in the report, energy resources derived from the ocean are “large, geographically diverse and can be a sustainable alternative” to powering offshore aquaculture. However, integrating ORE with offshore aquaculture operations cannot be done using a “one-size-fits-all” approach.

“Each technology used to extract energy from waves, tides, ocean currents, or thermal and salinity gradients presents both advantages and challenges for aquaculture,” wrote the report’s authors.

Wave energy devices can be used for onshore, nearshore or offshore aquaculture, but are particularly “well-suited” for offshore aquaculture. However, co-located wave and aquaculture projects need to be situated in areas that avoid waves that are too large for the aquaculture system or too small for the wave energy device to be effective.

“WEC (wave energy converters) have the potential to be suitable due to the wide variety of devices available,” said Freeman. “They can be placed on the seabed, they can be floating in the water column or on the surface, they can be attached to structures, such as piers.”

However, Freeman said WEC may not be ideal for high-energy sites, as these can be challenging for general operation and maintenance and aquaculture equipment that’s not built for these purposes.

For nearshore operations, tidal energy devices may be more appropriate, but there are challenges in application.

“The flow speed of tidal currents in energetic tidal channels could be a challenge for aquaculture operations,” wrote the authors.

Ocean thermal energy conversion (OTEC) holds promise for onshore, nearshore and offshore aquaculture in tropical and subtropical regions. It can provide cold, nutrient-rich water with fewer pathogens and bacteria and can produce desalinated water for use in aquaculture production.

“This is a really predictable resource that’s available year-round,” said Freeman. “OTEC infrastructure has the potential to be used for feeding systems and other aspects of aquaculture operations. But it has a high cost of technology installation.”

Overall, wave and tidal device technologies were identified as “more advanced” than the other ORE technologies. Ocean current technology was also considered, but the researchers found that it may not work as well for offshore aquaculture, as the locations “present challenges for underwater operations” (such as net repairs and diving). Likewise, salinity gradient technologies are usually located nearshore and provide brackish water that can be supplied to aquaculture operations, but these technologies are “less developed than other forms of ORE.”

Solar photovoltaic (PV) and offshore wind were also assessed as alternative renewable energy sources for powering aquaculture operations. The report did not cover offshore wind generation because “seawater is not the motive of power.”

Aquaculture energy demands ‘vary greatly’

Currently, the lack of data from the aquaculture industry on specific energy needs – particularly for offshore aquaculture – represents a hurdle to moving forward. Successful integration hinges on understanding the energy demands and energy-intensive resource requirements for specific aquaculture operations.

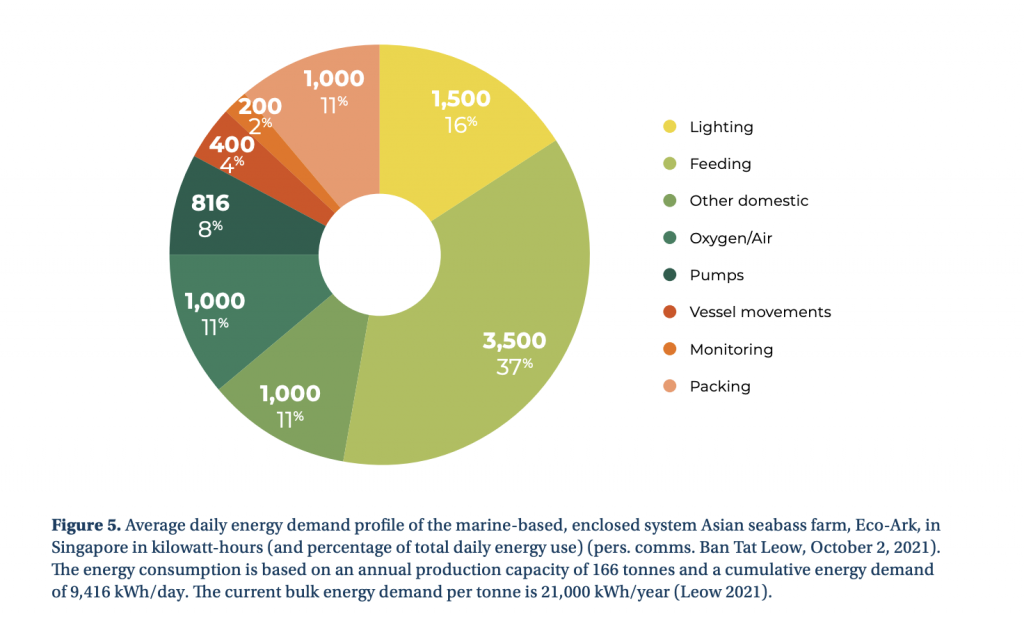

To fill this knowledge gap, the team studied the available energy information for several operations within the global aquaculture sector, including nearshore and offshore Atlantic salmon, nearshore Asian seabass or barramundi, and nearshore oyster and mussel operations.

The findings reveal that the energy demands “vary greatly” by operation and species. For example, a nearshore Chilean Atlantic salmon farm has an estimated cumulative energy demand of 371 kWh per day; whereas a marine-based, enclosed systems Asian sea bass farm in Singapore requires an estimated 9,416 kWh per day.

“With the Atlantic salmon [examples], there’s no need for water filtration or water heating, as the fish are largely grown in situ in the marine environment,” said Eloise Wilson, project lead at Blue Economy CRC. “Looking at the Asian sea bass example, that’s a largely intensive operation. That means that the Asian sea bass require constant water aeration, water filtration and water heating or cooling, depending on the seasons. So that would drive the energy consumption up.”

Such findings considered, the report gives a snapshot into the energy requirements for marine-based aquaculture operations worldwide and how power solutions need to be optimized based on various factors, such as the species and operational needs.

‘Great opportunities’

The report details a series of “lessons learned” from 12 case studies, which explored marine-based aquaculture projects that have used ocean energy, solar photovoltaic, offshore wind technologies, or hybrid solutions to meet the energy demands of aquaculture. These include all marine-based aquaculture types (finfish, shellfish, crustacean, and seaweed; nearshore and offshore) and a diverse range of renewable energy technologies. But despite the success stories, one barrier to advancement is cost.

“It was found that there’s a high cost of offshore equipment related to limited investment,” said Lysel Garavelli, a research scientist at PNNL.

To address various hurdles, the report offers a series of recommendations to “aid synergies” between ORE and offshore aquaculture and advance co-location, which are grouped into three main areas (technical and operational processes, regulatory processes, and economic impact). Despite the challenges, the authors argue that co-location offers “great opportunities” for both industries, offering benefits such as cost savings, shared maintenance and operations systems, and sustainable and efficient use of marine space.

“Although offshore aquaculture and ORE are nascent industries, there is much potential for advancement to help tackle larger problems of feeding the growing population, reducing carbon emissions and contributing to a sustainable blue economy,” the authors concluded.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lisa Jackson

Associate Editor Lisa Jackson lives in Hamilton, Ontario, Canada. Her work has been featured in Al Jazeera News, The Globe & Mail, The Independent, and The Toronto Star.

Tagged With

Related Posts

Intelligence

After first harvest, offshore aquaculture venture in Qatar sets fresh ambitions

With a successful sea bass harvest last fall, Qatar’s only offshore aquaculture venture now seeks to double production and diversify into other species.

Intelligence

Innovasea helps secure grant to repurpose defunct Gulf of Mexico oil rig

U.S. offshore aquaculture technology company says a $100,000 federal grant will go toward repurposing a defunct oil rig in the Gulf of Mexico.

Intelligence

Offshore aquaculture offers a climate change solution, but can farms withstand severe weather events?

The success of open-ocean aquaculture depends on structures that can withstand extreme waves and harsh winds linked to climate change.

Intelligence

Paper seeks to quell ‘myths and unfounded criticisms’ of marine aquaculture

Open-access paper refutes prevalent criticisms about marine aquaculture and what it calls “myths and assumptions” about offshore fish farming.