Male tilapia grow faster than females

Annual global tilapia production has now surpassed 3 million metric tons (MT) and will continue to grow exponentially if high-quality fry are readily available. However, how to supply such a huge quantity of fry has been a question for countries with the potential to expand tilapia farming for domestic consumption and export markets.

Thailand has already achieved suff-icient seed production, and Bangladesh is now approaching it. Countries such as the Philippines and Vietnam are also struggling with the issue. Considering the population growth and rapid increases in health-conscious middle-class families, seafood demand in most countries is going to be much higher than at present. Strategic planning is needed to fulfill the demand for fish.

Natural breeding without the need for any hormone injection was considered the main advantage of tilapia over other species, but as farming became more commercial, demand for large and uniform fish increased. This created high demand for good-quality fry.

It was almost impossible for hatcheries to supply the large quantity of fry using traditional methods of collection from ponds due to the low number of eggs per spawn and asynchronous spawning that made the production of millions of fry unfeasible. The production of a sufficiently large quantity of quality seed remained a big problem in Thailand in the early 1980s.

Monosex fry

The solution was to produce all-male fry, since male tilapia grow faster than females. A large number of broodfish were maintained in hapas, and their eggs were incubated artificially in a clean and controlled system. After hatching, the fish received high-quality feed containing methyltestosterone as early as possible to ensure over 99 percent males in the fry population.

Challenges included the development of efficient methods and selection of containers for the artificial incubation of eggs that would ensure consistently high hatching rates and survival of eggs and yolk-sac larvae to swim-up fry.

Soft drink bottles and white water bottles were tried, but locally made semi-transparent fiberglass jars were found to function better. The larger incubators can accommodate 200,000 to 300,000 eggs. Recently, simple plastic jars or jugs have also been used, as they are cheap, easily available and more transparent, so hatchery operators can see the egg movement easily. They are also lighter and easier to handle than the fiberglass jars.

As tilapia eggs are heavy and remained at the bottom of the incubators, they needed to be moved gently to avoid injury and get adequate oxygen. Down-welling water flowed into the jars to keep the eggs suspended in the water.

Attempts were also made to maintain high survival and increase the percentage of males in the fry populations. These efforts included determining the optimum dose of methyltestosterone in feed, as well as the frequency and length of feeding period. As demand for fry is seasonal, a method of advanced nursing has been developed that can be applied when fry must be kept longer periods.

Research is still ongoing to further maximize productivity through improvements in the survival of fry, development of cold and salinity tolerance, solutions to summer heat stress that drastically reduces egg production, treatments for emerging diseases and cost reductions.

Technology dissemination

A remaining challenge is how to disseminate the monosex fry technology as widely as possible. The Asian Institute of Technology, where the procedures were developed, applies three major distribution strategies.

Public-private partnerships

A number of attempts have been made to disseminate the technology through public and government organizations with the aim of supplying large numbers of high-quality monosex tilapia fry. However, the results were not up to expectations, probably due to the organizations’ failure to fully grasp the potential of tilapia farming. At the same time, a lack of incentives in the traditional extension systems did not encourage individuals and the organizations to prepare for a potential massive expansion.

A breakthrough occurred when a private company picked up the technology through a contractual arrangement and demonstrated that supplying up to 240 million fry yearly was possible. Based on this level of production, the establishment of only about five large-scale hatcheries could supply a billion fry per year.

Although the monosex technology was thought to be cumbersome, the private sector adopted it quickly due to its profitability and increasing demand. More importantly, after the successes in the private sector, the public sector has refocused on this technology.

Short-term training

Successful research and development attract the interest of people in short-term, need-based skill development training. In a poplar course titled “Techniques for Mass Fry Production and Grow-out,” the Asian Institute of Technology trained about 1,000 personnel from 30 countries over a decade. Over 200 participants were from Bangladesh, while nearly 200 came from Vietnam, and 100 were from Cambodia.

Most participants were attracted to the hands-on work experience in a tilapia hatchery. Many officials of the governments and research institutions who received the training established tilapia hatcheries in their countries, including Bangladesh, Thailand and Vietnam.

Although the scale of operation remained small, the training helped in promoting tilapia – not only in Asia but also in Africa and the Americas. Recently, increasing numbers of private companies have sent their staff for training when they plan to establish tilapia hatcheries. Because of the proven technology, private companies are confident they can boost production and get the investment back within two years. Several from Bangladesh also asked for technical assistance and quality-monitoring services.

Aqua-internship program

Recently, the Asian Institute of Technology (AIT) established an Aqua-Internship Program that targets university students and recent graduates. Interestingly, tilapia hatcheries have been one of the program’s more attractive placements.

AIT and its partners in Bangladesh, Nepal, Thailand, Vietnam and other countries offer internship programs to their students as well as students from abroad to provide on-the-job work experience. Students enrolled in their universities’ biology, marine science or related disciplines typically join the internship program. They learn the techniques by doing the work as regular hatchery staff for two to six months. These hatcheries also provide opportunities for students to carry out research afterwards, and may even employ them in some cases.

It is hoped that this flexible learning and technology transfer program that provides specific skills will help solve the shortage of skilled human resources for the tilapia hatchery business and ultimately boost tilapia farming around the globe.

(Editor’s Note: This article was originally published in the November/December 2011 print edition of the Global Aquaculture Advocate.)

Authors

-

Ram C. Bhujel, Ph.D.

Coordinator

Aqua-Internship Program

Asian Institute of Technology

P. O. Box 4

Klong Luang, Pathumthani 12120 Thailand[111,102,110,105,46,107,110,105,108,97,105,115,97,45,114,97,97,64,114,111,116,97,110,105,100,114,111,111,99]

-

Mark Woollard

Aqua-Internship Program

Asian Institute of Technology

P. O. Box 4

Klong Luang, Pathumthani 12120 Thailand

Tagged With

Related Posts

Intelligence

Bangladesh’s tilapia aquaculture industry shows resilience

Tilapia aquaculture in Bangladesh has developed significantly since 1999, based on the Genetically Improved Farmed Tilapia (GIFT) strain of Nile tilapia (Oreochromis niloticus) introduced from Malaysia and on the significant genetic improvement research work by the Bangladesh Fisheries Research Institute (BFRI).

Health & Welfare

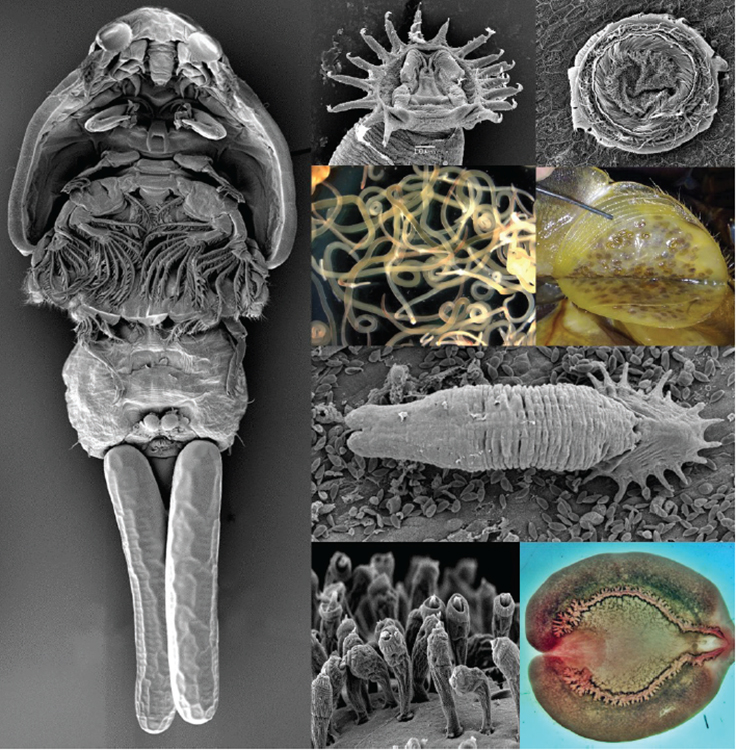

Economic impacts of aquatic parasites on global finfish production

Obligate and opportunistic parasites play a critical role in determining the productivity, sustainability and economic viability of global finfish aquaculture enterprises. Without stringent and appropriate control measures, the impacts of these pathogens can often be significant.

Health & Welfare

Successful production of Nile and blue tilapia fry

The relationship between production in subtropical earthen ponds of fry suitable for hormonal sex inversion and degree days was quantified for Nile tilapia (Oreochromis niloticus; Egypt strain) and blue tilapia (O. aureus).

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.