Treatment technologies for aquaculture wastewater based on microalgae are considered promising solutions with high application potential

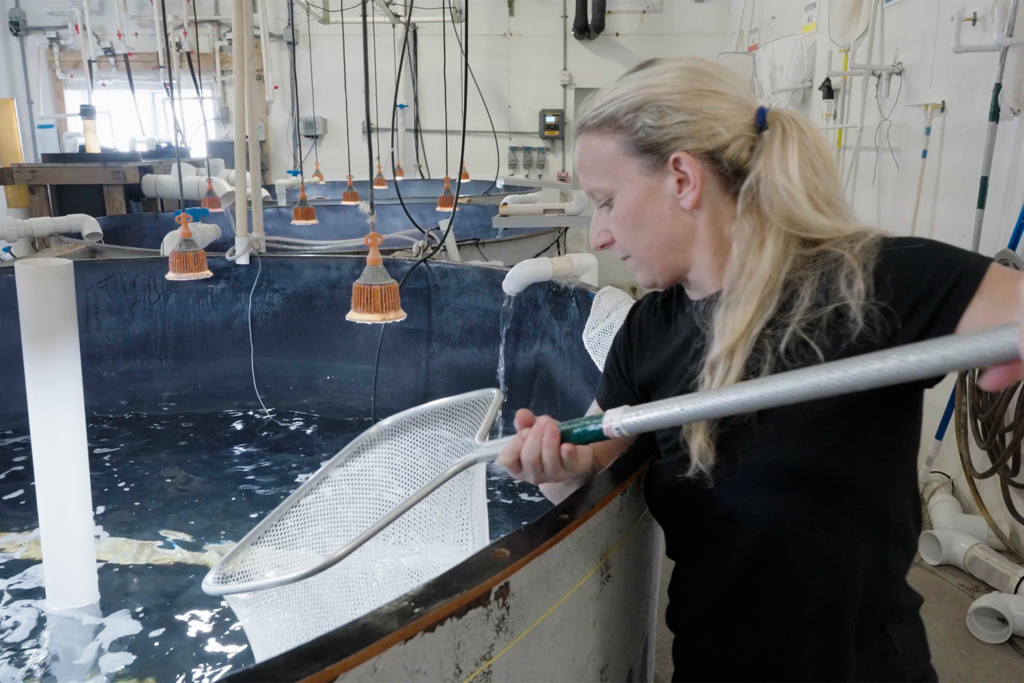

Aquaculture wastewater (AWW) contains significant amounts of organic matter (100–150 mg per liter), nitrogen (3–7 mg/L as ammonium and 2–110 mg per liter as nitrates), and phosphorus (2–50 mg per liter as phosphates), which, if left untreated, can contribute to pollution and eutrophication in aquatic ecosystems. However, this wastewater can be effectively utilized in integrated systems with microalgae to ensure the recycling of nitrogen and phosphorus for the production of algal biomass.

The integration of wastewater treatment with microalgae cultivation is not only beneficial from an environmental point of view, but in terms of economic viability. A review of recent advances in the utilization of AWW for algae cultivation has shown that microalgae can produce biomass rich in proteins, lipids, carbohydrates, and vitamins, making them ideal candidates for animal feed and food ingredients. Microalgae biomass can also be a food source for fish.

In addition, the lipids produced by microalgae can be further processed into biodiesel, carbohydrate-rich biomass is suitable for bioethanol production, while the anaerobic digestion of microalgae biomass leads to the production of biomethane, all renewable energy sources. Microalgae have also been shown to contribute to soil health and fertility when processed into biofertilizers and are an acceptable alternative to chemical fertilizers. There are many types of microalgae that could be supported by the nutrients available in AWW.

The ability to utilize wastewater of different chemical composition and origin as a cultivation medium is one of the main advantages of microalgae biomass production systems. It has been shown that such an environmentally friendly approach can significantly reduce the total cost of ownership of cultivation facilities and the unit cost of biomass production.

This article – summarized from a section of the original publication (Zieliński, M. et al. 2025. Integration of Aquaculture Wastewater Treatment and Chlorella vulgaris Cultivation as a Sustainable Method for Biofuel Production. Energies 2025, 18(16), 4352) – discusses the potential and challenges of microalgae production systems for wastewater treatment, including aquaculture wastewaters.

Siting photobioreactors

In addition to aquaculture applications, numerous attempts have been made to integrate microalgae photobioreactors into industrial, municipal and agricultural wastewater treatment processes, as well as into the neutralization of wastewater from biogas plants and anaerobic reactors. In most reported cases, a high removal efficiency of organic pollutants as well as nitrogen and phosphorus compounds was achieved. Reports of photobioreactors effectively neutralizing wastewater from industrial and domestic sources indicate the feasibility of commercial systems for the production of microalgae biomass, including for the production of biofuels.

There are many concepts for siting photobioreactors near agricultural biogas plants, waste-to-biogas plants, wastewater treatment plants, district heating and cogeneration plants, landfills, and other industrial facilities that generate both CO2 and nutrient-rich wastewater. Promising research results have prompted institutions to incorporate microalgae technologies into environmental and energy strategies.

An example of this is the European Union’s framework for the development of the bioeconomy, in which microalgae occupy an important place as a raw material for environmental protection technologies, bioenergy production, and the extraction of high-quality nutrients for the food and feed industries. The microalgae sector is expected to play an increasingly important role in the EU’s blue bioeconomy, especially in coastal areas.

Complex but promising biotechnology solutions

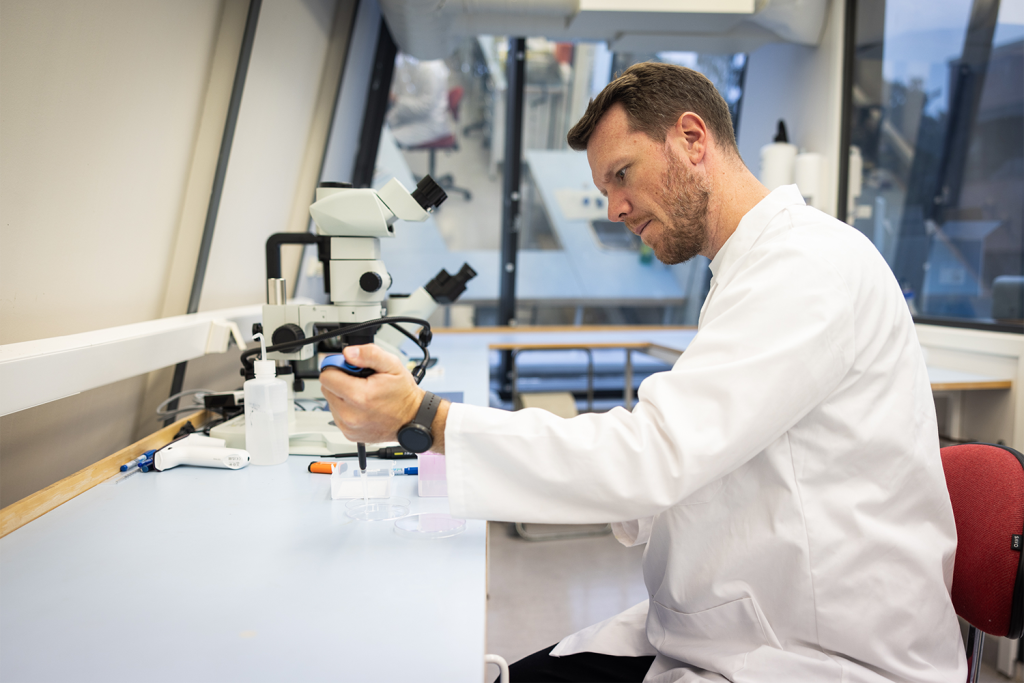

The literature shows that microalgae cultivation technologies are among the most promising and sustainable solutions in the field of biotechnology. Numerous studies have emphasized their competitiveness, cost-effectiveness, and potential for biofuel production. Despite significant research progress and extensive experimental data, implementation on an industrial scale is still limited. It remains crucial to determine which technological aspects need to be optimized and which obstacles need to be removed in order to fully exploit the potential of this technology.

Microalgae systems based on the utilization of wastewater and the subsequent conversion of the biomass into biofuel are complex processes that depend on numerous factors and parameters, which significantly limit their commercial applicability. These technologies are much more complex compared to the conventional methods of wastewater treatment and waste-to-energy conversion. In activated sludge-based processes, for example, the design of large-scale plants is based on several key parameters, including the concentration of bacterial microflora in the bioreactor, the organic load of the sludge, the hydraulic load, and the oxygen content.

Anaerobic processes are even simpler – their design and operation are mainly based on the organic load index and hydraulic retention time. The relative simplicity of these solutions is an important factor in their widespread application. It should be stressed that these systems compete to some extent with microalgae technologies, as they generate surplus sludge that can be used to produce fuels.

Most research to date at laboratory scale

Most experiments on the use of microalgae in wastewater treatment are conducted at laboratory scale, which is a significant obstacle to industrial implementation. While small-scale studies are invaluable for understanding biochemical mechanisms and testing different technological variants, they often do not provide the data required for economic, environmental, and technical assessments at the industrial level. Information on the energy balance, carbon footprint, material flow analyses, and long-term process stability, among other things, is lacking.

In order to increase the technology readiness level, a gradual transition from laboratory to pilot scale to large-scale operation is required. This phase is crucial for the precise definition of the type of raw materials, materials, equipment, and process parameters. However, there are few reports in the scientific and technical literature describing the technical and operational aspects of large-scale microalgae plants.

Life cycle assessments are crucial

In the context of environmental assessment, life cycle assessment (LCA) plays a crucial role. It enables a reliable assessment of potential waste streams (including wastewater, leachate, and waste gases) as elements to increase economic and environmental efficiency. The LCA results are important both for the optimization of the cultivation process and for the preparation of the environmental documentation required for investment processes. The integration of LCA results into design decisions enables the minimization of the environmental impact of the technology and the improvement of its efficiency.

Symbiotic systems: A new research direction

A new research direction that can significantly impact the efficiency of wastewater treatment with microalgae is symbiotic systems that combine microalgae with bacteria, fungi, or yeasts. Current work focuses on the optimization of cultivation conditions, the analysis of interactions between autotrophic and heterotrophic organisms, and their effects on technological parameters. In such systems, microalgae enhance the processes of nutrient degradation and produce oxygen, which supports the metabolism of aerobic microorganisms. Heterotrophic microorganisms, in turn, break down organic pollutants into mineralized forms of elements and thus support the growth of microalgae.

Another significant advantage of symbiotic systems is the improved sedimentation properties of the biomass, which translates into lower costs for separation and dewatering, accounting for up to half of the total process costs. In addition, such systems have been shown to have a positive impact on the quality and quantity of biofuels and other products with market value.

Bioenergy production technologies slow to materialize

Despite ample scientific evidence confirming the potential of microalgae for bioenergy production, these technologies have been slow to materialize. At their current stage of development, they cannot compete with fossil fuels, and the volatility of their prices makes it even more difficult to predict the return on investment. Utilizing wastewater as a nutrient source can improve the profitability of microalgae plants, but requires pre-treatment to eliminate pathogens, to remove impurities, and to reduce turbidity. High levels of organic matter and sulfur in the medium can promote the growth of competing microorganisms, limiting microalgae growth and process efficiency.

The main obstacles to the development of microalgae technologies include the complexity of the cultivation process, the lack of data from pilot and large-scale plants that allow for a reliable assessment of the life cycle assessment, and insufficient regulatory and financial support. Possible areas for improvement include process optimization, the use of genetic engineering and the development of advanced process monitoring and control systems.

Perspectives

Treatment technologies for aquaculture wastewater based on microalgae are considered promising solutions with high application potential. However, there are barriers that significantly limit their rapid diffusion. The main limitations include the complex and technologically demanding processes of biomass cultivation and harvesting, as well as the insufficient amount of operational data from pilot and large-scale plants, which often prevents a reliable assessment of technological efficiency and cost-effectiveness.

Given current technological advances, further performance improvements could be achieved through the application of optimization techniques, genetic engineering, and improved process control and monitoring.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Marcin Zieliński

Corresponding author

Department of Environment Engineering, Faculty of Geoengineering, University of Warmia and Mazury in Olsztyn, Str. Oczapowskiego 5, 10-719 Olsztyn, Poland[108,112,46,117,100,101,46,109,119,117,64,105,107,115,110,105,108,101,105,122,46,110,105,99,114,97,109]

-

Marta Kisielewska

Department of Environment Engineering, Faculty of Geoengineering, University of Warmia and Mazury in Olsztyn, Str. Oczapowskiego 5, 10-719 Olsztyn, Poland

-

Annamaria Talpalaru

Faculty of Chemical Engineering and Environmental Protection “Cristofor Simionescu,” “Gheorghe Asachi” Technical University of Iasi, 70005 Iaşi, Romania

-

Paulina Rusanowska

Department of Environment Engineering, Faculty of Geoengineering, University of Warmia and Mazury in Olsztyn, Str. Oczapowskiego 5, 10-719 Olsztyn, Poland

-

Joanna Kazimierowicz

Department of Water Supply and Sewage Systems, Faculty of Civil Engineering and Environmental Sciences, Bialystok University of Technology, 15-351 Bialystok, Poland

-

Marcin Dębowski

Department of Environment Engineering, Faculty of Geoengineering, University of Warmia and Mazury in Olsztyn, Str. Oczapowskiego 5, 10-719 Olsztyn, Poland

Related Posts

Innovation & Investment

20,000 lettuces under the sea: Could underwater agriculture be the future of farming?

Preliminary research suggests that emerging mariculture methods could provide alternatives to land-based agriculture and within recirculating systems.

Responsibility

A circular economy approach to transform the future of marine aquaculture

Marine microalgae-based aquaculture has the potential to provide greater than 100 percent of global protein demand by 2050.

Innovation & Investment

‘Synergies between land and ocean’: Regenerative farming accelerator eyes a faster-growing blue economy

Pine Island Redfish, a Florida-based aquaculture startup, joins Bright Tide's accelerator to advance regenerative farming practices.

Aquafeeds

Can microalgae treat wastewater and be a valuable alternative fish feed ingredient?

Stian Borg-Stoveland of the University of Agder says Norway’s priority when developing salmon feed is alternative ingredients for oils and proteins.