Quantifying major wastes and byproducts from aquaculture across a full range of production types

To sustainably intensify aquaculture and maintain a continuous seafood supply, there is a need to implement a more resource-efficient approach and minimize aquaculture waste. Thus, there is growing global awareness and interest in the valorization of available resources – specifically nutrient recycling and using byproducts – to support a circular economy within aquaculture. There is potential for byproducts and wastewater effluents to be diverted back into aquaculture systems and account for high percentages of aquaculture production.

This article – adapted and summarized from the original publication (Campanati, C. et al. 2021. Sustainable Intensification of Aquaculture through Nutrient Recycling and Circular Economies: More Fish, Less Waste, Blue Growth. Reviews in Fisheries Science & Aquaculture 30:2, 143-169) – reviews the major wastewater constituents from effluents of different aquaculture systems to highlight potential areas for nutrient and byproduct recycling, key challenges in the reuse of side streams and potential solutions to overcome these challenges, to provide sustainable aquaculture options for the future.

Major effluents and byproducts in aquaculture

Seafood processing byproducts

Seafood byproducts are a large and highly valuable resource, already being recycled for other uses, and there is potential to increase this further to benefit the aquaculture industry. Byproducts include damaged fish, body parts not usually utilized for direct human consumption and trimmings from fish processing and canning.

Today 11.5 percent of total global seafood produced (19.7 MT) is not used for direct human consumption. More than 4.7 MT of byproducts are generated from fish processing, and a further 0.5 MT from crustaceans and mollusks as carapaces, exoskeletons and shells. At present, 30 percent of fishmeal and fish oil production (up to 54 percent in Europe) is derived from byproducts. With the intensification of aquaculture, there is the potential and expectation that the recycling of seafood byproducts for feed and other uses will increase.

Wastewaters and solids generated during seafood processing and fishmeal and fish oil production represent a recycling opportunity. The mechanical pressing of seafood during fish oil preparation produces effluents with a high organic content (e.g., Chemical Oxygen Demand, COD 80–120 grams per liter). Suspended solids in wastewaters from fish processing contain significant levels of dissolved organic carbon, total phosphorus (TP), total nitrogen (TN), and oil and grease.

The volumes of wastewater produced are large: Studies suggest between 15 and 17 liters of effluents are produced per kg of fish from skinning and canning, respectively. Seafood byproducts are a highly valuable resource and in such great demand – such as for producing omega-3 rich aquafeeds – that additional sources, such as microalgae and polychaetes, are already needed to bridge the market demand-supply gap. Increased re-use of seafood byproducts would have significant economic, environmental and resource use efficiency benefits.

Integrated utilization of microalgae grown in aquaculture wastewater

Dissolved and solid effluent materials

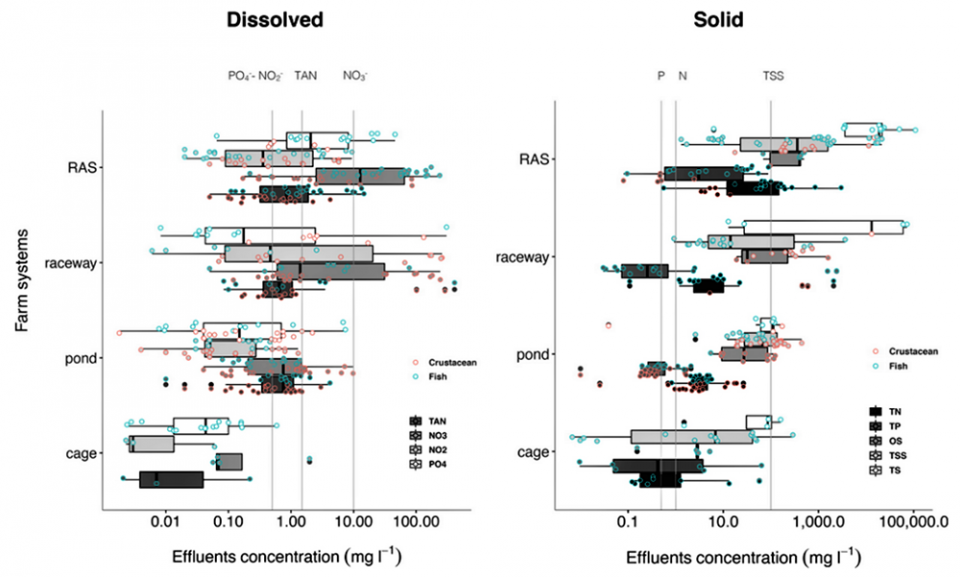

Aquaculture effluents are composed mainly of dissolved and settleable nutrients from unconsumed food and feces of farmed species. The amount and type of discarded material produced from aquaculture depends on factors including dietary supplementation, the metabolism and feeding habits of the farmed species and consequently feed conversion efficiencies. Aquaculture facilities are supposed to follow guidelines for best practices – such as those produced by the U.S. Environmental Protection Agency (EPA), Food and Agricultural Organization (FAO) or Best Aquaculture Practices (BAP) – in the management of effluent production (Fig. 1).

Recirculating aquaculture systems (RAS) and raceway systems can produce wastewaters with high concentrations of solids and nutrients, which can be useful resources if treated effectively. To evaluate reuse options realistically discharge rates must be considered. RAS, for example, has low water exchange, produces effluents at 1,000 times lower rates compared to raceways, and are more concentrated compared to ponds and cages. The paucity of cage effluents studies urges a more careful and standardized method for monitoring compound concentration, to allow better comparison across systems. In ponds and cages, efficient management of solids can make use of significant quantities of reusable biomass and maximize production through in-situ nutrient upcycling with polycultures and multi-trophic systems.

Wastewater solids

Solid waste is a key component of aquaculture wastewaters, generally holding 10 to 30 percent of the total nitrogen (TN) and 30 to 80 percent of the total phosphorus (TP) discarded in feces or uneaten food, and is usually retained from effluents in a primary treatment. Feed digestibility determines feces consistency, quantity and form (suspended or settled) of solids in wastewaters. Settleable solids (>100 µm) sink to the bottom of the water column and are more easily removed compared to suspended solids (30–100 µm). Dietary stabilizers and binders such as guar gum or alginate are often added to feeds to increase feces particle size and thus facilitate their sinking and removal processes.

Due to difficulties in their removal process, suspended solids are considered major pollutants within aquaculture wastewaters. Suspended solids, which can derive from different sources (e.g., feed, feces, detached biofilm, sediments and system enclosures’ substrates), are mostly organic particles and can drive bacterial proliferation, which can clog biofilters in the system. Elevated TSS levels also increase turbidity and reduce light penetration, limiting in-situ autotrophic remediation and the visual inspection of farmed species health. Elevated TSS can negatively impact farmed species, by impairing gill functioning and facilitating pathogen infections in aquaculture stock. Regardless, careful monitoring of TSS levels is required to reduce the risk of bacterial proliferation from fine solids availability.

Sediments in ponds or beneath cages and pens act as major sinks for excreted N (∼30 percent of output), P (∼80 percent), organic matter (∼60 percent) and solids (∼90 percent) and can contribute to a thick harvestable sludge, which can negatively affect water quality and biodiversity. Effective sludge thickening methods can reduce effluent volume for practical storage, off-site transport and composting, and further concentrate nutrients for other applications.

Wastewater dissolved nutrients (nitrogen and phosphorus)

Nitrogen (N) is one of the most significant components of aquaculture wastewaters. Differently from freshwater ecosystems, which are usually P-limited, marine ecosystems are generally N-limited. Therefore, N has a primary role in the risk of producing eutrophic systems. Most of the N released from aquaculture (60–90 percent) is in dissolved form, predominantly as ammonia.

Reducing the quantity of N excreted by target species is achieved in some systems through “protein-sparing.” This involves replacing protein with a higher level of lipids in fish feeds, or more carbohydrates for crustacean feeds. Nutrient leaching from feeds can be further reduced with specific feeding formulations such as in the form of microencapsulated diets.

Phosphorous (P) is a second major component of aquaculture wastewaters. Around 25–85 percent of P lost from feed in aquaculture is in solid form within feces. The high levels of P in fish oil and fishmeal, are largely excreted by farmed species. Vegetable-based meals and oils contain lower levels of P but are inadequate alternatives for 100 percent fish meal or fish oil substitution, particularly for carnivore species. Digestibility and bioavailability of P from vegetable-based feeds can be enhanced through additional phytase enzymes, feed pretreatments, and organic acid supplementation in diets. Additionally, although still not widely implemented, breeding programs exist to select carnivorous fish over generations for better growth and feeding efficiency on plant-based diets. Further optimizations in feed formulations and inclusion rates in the diet are suggested to reduce P losses further.

Key nutrient recycling opportunities in aquaculture

The application of both established and newly emerging recycling methods to aquaculture has great potential to make the industry more sustainable and to greatly increase production output. Retrieved solids, dissolved nutrients and seafood byproducts can all be reused to benefit aquaculture itself, and also other industries including agriculture and nutraceuticals. As just one example, recycling of omega-3 fatty acids from seafood byproducts and the use of bioremediating microalgae and filter-feeders (e.g., polychaetes, bivalves) can enable a large increase in the supply of omega-3 oils, with significant economic and human health benefits.

Energy generated from sludge digestion, clean water retrieved from bioremediation and upcycled nutrients through integrated aquaculture systems could each help sustain intensive arable farming. The following recycling methodologies have the potential to play primary roles in establishing sustainable circular economies in aquaculture.

Byproduct recovery

Seafood byproducts can be recovered for use in multiple high-value industries including aquaculture, agriculture and the food and pharmaceutical industries. The most common reutilization of seafood byproducts remains integrating them back into food or feed ingredients for aquaculture. As valuable sources of high-quality proteins (20–70 percent) and energy (19 percent lipids), seafood byproducts are widely used as animal and pet feed. There is potential to make more effective use of wastewater derived from trimmings and silage processing into fishmeal and fish oil. Wastewater from seafood byproducts processing (e.g., 1,300 cubic meters per day from 170 tons of tuna/day) can be reused after solid filtration as a medium for algal growth. Over 360 grams per day of microalgal biomass (50 grams of lipid per day) can be obtained from 1 cubic meter of fish processing wastewater (88 percent organic matter, 6.5 percent total nitrogen, TN, 0.6 percent TP).

Extracted and isolated bioactive compounds and natural pigments such as carotenoids, collagen and protein hydrolysates from seafood byproducts, are of interest for functional food, nutraceuticals and pharmaceutical use due to their antihypertensive, antioxidative, anticoagulant and antimicrobial properties. Currently, these high-value components are retrieved in too small amounts for a cost-effective resource recycling process, but more effective extraction methods could change this.

Wastewater solids recycling

Land application is the most common recycling use of solids from hatchery settling ponds, basins and RAS effluents. Nutrient-rich aquaculture sludges are valuable bioresources for land plant fertilization, improving or maintaining soil structure, while decreasing the environmental impacts caused by mining and artificial fertilizers. Generally, aquaculture sludge contains lower toxic and health-concerning components compared to sludges retrieved from industry and domestic treatments. Composting of aquaculture wastewater, combined with sludge dewatering and C:N ratio alteration when needed, can reduce biosolid pathogens. Sediments retrieved from ponds after each aquaculture production cycle could be dried and reused for fertilizing ponds, mangrove reforestation, fertilization of soil and/or fodder grass.

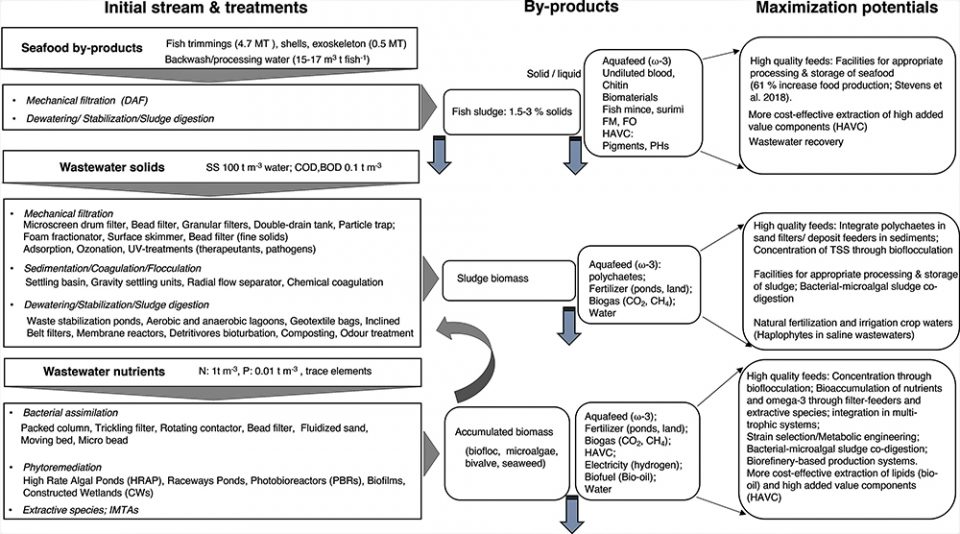

Solids retrieved from aquaculture could also be used as feedstock for vermicomposting, which has already been used for treating high-moisture-content organic material discarded from agricultural, industrial and municipal sources, with production rates of 0.30 kg vermicast per kg of worm/day, which can be used as feeds. Marine polychaete worms could also be included in integrated recirculation systems and be fed on aquaculture effluents. Worms could be easily included in experimental food webs for wastewater bioremediation and fatty acid enrichment of farmed species (Fig. 2). For example, more than 50 percent of solids derived from pond wastewaters can be removed using sand filters filled with polychaetes, which can produce 3 to 4 grams per liter of yieldable biomass and 20 mg of omega-3s per liter.

Aquaculture sludge treated in anaerobic digesters can produce biogases useful for energy production. This includes methane (17 to 30 percent of organic carbon input) and carbon dioxide (Fig. 2). The combination of biological (anaerobic digestion) and thermochemical (gasification) conversion of biomass has shown to be advantageous for energy recovery from municipal sludge. Partially due to the lower amount of solids retrieved, however, the concentration of biogases from anaerobic digestion of aquaculture sludge is currently lower than those produced from industrial or domestic sludge.

For example, methane production was reported in the range of 0.02 to 0.25 liters per gram of COD added. Several studies suggest that 5 percent of RAS energy demand could be met by biogas production from anaerobic digestion of sludge. Further investment in anaerobic digestion and thermochemical systems could significantly increase this value and help build a circular economy in aquaculture regarding energy supply.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Camilla Campanati, Ph.D.

Corresponding author

Department of Zoology, University of Cambridge, Cambridge, UK[107,117,46,99,97,46,109,97,99,64,49,49,48,50,99,99]

-

David Willer, Ph.D.

Department of Zoology, University of Cambridge, Cambridge, UK

-

Jasmin Schubert, Ph.D.

RethinkResource, Hohlstrasse 400, Zurich, Switzerland

-

David C. Aldridge, Ph.D.

Department of Zoology, University of Cambridge, Cambridge, UK

Tagged With

Related Posts

Responsibility

Circular economy: Hydrolysates of aquaculture byproducts as feed

In the latest GAIN article, fish scraps can be transformed into fish protein hydrolysates as a high-nutrient value addition to aquafeeds.

Responsibility

An introduction to circular economy principles in aquaculture

In the latest article from the GAIN project, implementing circular economy principles can help increase the sustainability of aquaculture production.

Aquafeeds

Mexican startup offers DIY aquafeed solution by upcycling wastewater

MicroTERRA is a promising Mexico-based startup developing systems that use microalgae to turn fishpond wastewater into protein for fish feed.

Responsibility

Conscious coupling: Can IMTA gain a foothold in Europe?

Integrated multitrophic aquaculture (IMTA) isn’t widely practiced in Europe but new findings indicate that farming multiple species on one site can work.