The latest series of articles from the GAIN project, funded by the EU Horizon 2020 Fund, examine waste reduction, byproduct usage

This is the first article in our series on the “circular economy.” This is part of a larger three-part series on sustainable aquaculture intensification in Europe, focused on “precision aquaculture,” “sustainable feeds” and “circular economy.” This work from the GAIN project is funded by the EU Horizon 2020 Fund. Each part in this series takes provides an introductory glance at the three topics, then explains how outputs from the GAIN project are contributing towards it, including the applicability to industry and governance.

Traditional production models are linear, where new resources and materials are put into production systems to create a final consumer product. This model considers inputs, a production process that transforms and adds value to the original resources in combination with each other, leading to outputs. Outputs include the final consumer product as well as waste products. This order of activities from initial materials, production, outputs and sales is referred to as a “value-chain.”

In contrast, the circular economy model for food products focuses on the reuse of “waste” byproducts, such that the value-chain outputs become inputs for other value-chains. For example, fish processing produces fillets as well as leftover scraps, skins and trimmings of fish. These scraps can then be used as ingredients in pet feed. The circular economy also encourages valorizing byproducts that might otherwise be disposed of and reusing or recycling other items at the end of their useful life. For example, crustacean shells can be processed into biodegradable packaging.

Circular economy principles reduce waste, increase efficiency and support more sustainable systems. By reducing waste, the value extracted from the natural resources is increased. In other words, we get more, using less. This is particularly important as we aim to feed an ever-growing population.

Life-cycle analyses (LCA) are often used to measure the environmental impact of a value chain. An LCA typically measures the total carbon footprint of the product, considering all the raw materials and processes used to create that product from inception to sale. When circular economy principles are included, an LCA shows dramatic decreases in environmental impacts.

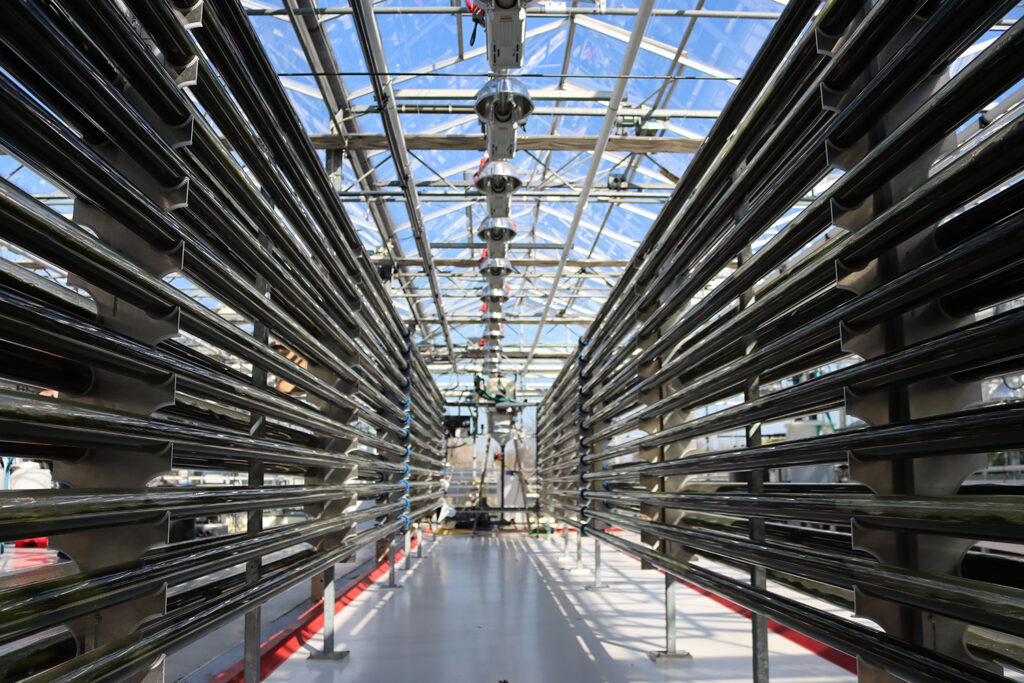

These principles are being applied in aquaculture to reduce its environmental impact. The reuse of byproducts in aquaculture is particularly important, as large amounts of shells and bones from processed fish and seafood is considered waste. A wide range of products can be produced from bones and shells, such as gelatin, collagen, biofuel, packaging materials and chitin, commonly used as a preservative for its antimicrobial properties.

Other aquaculture waste materials can also become recycled. For example, fish sludge can be used to culture black soldier flies, which are then used for insect meal, a protein ingredient in aquafeeds. This process reduces the amount of sludge discharged as waste into the environment, and also allows for the uptake of residual nutrients in the sludge. This means that less nutrients are wasted as they are retained within the system.

Unfortunately, regulations have not caught up with many of these technologies and prevent their use in the industrial mainstream. Regulatory bodies, particularly in the EU, are being encouraged to adapt and change their policies around waste re-use, such that circular economy practices can have greater impact throughout the industry. Circular economy practices could also be encouraged by certification bodies that can help improve on the sustainability of our global aquafood production systems.

Regulatory bodies will need to consider ways to encourage safe circular economy practices. The importance of reducing the risk of disease transmission has never been clearer. One way to do this is by avoiding the reuse of waste within the same production system: For instance, waste from marine species could be used for freshwater species, as bacterial colonies are unable to tolerate drastic changes in salinity levels. Testing and quality assurance would also help address safety concerns around waste reuse.

The following articles in this series will explain outputs by the GAIN project partners who have focused on developing innovative solutions for industry to embrace circular economy principles.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Alexandra Pounds

Assistant Researcher in Aquatic Food Security

Institute of Aquaculture

University of Stirling

Tagged With

Related Posts

Aquafeeds

A primer on sustainable feeds: Improving aquafeeds for sustainability, fish welfare and human nutrition

Improving aquafeed formulations can augment the sustainability and efficiency of aquaculture production – a new series from the GAIN project.

Intelligence

Precision aquaculture, part 1: Data and evidence-based management

Adopting precision aquaculture can aid a farm’s integration with the community. Learn more in the first article from the GAIN project.

Intelligence

Precision salmon: Optimizing welfare through data-driven insights

The GAIN project’s precision aquaculture series continues with a look at how data-driven insights into salmon behavior can aid farm management.

Aquafeeds

Sustainable feeds: Microalgae as a source of minerals in aquaculture

As seen through the GAIN project, adopting precision aquaculture tools improve feeding strategies and preventative measures for sea bass.