Artificial intelligence can boost aquaculture’s performance in environmental reporting, quality control and so much more

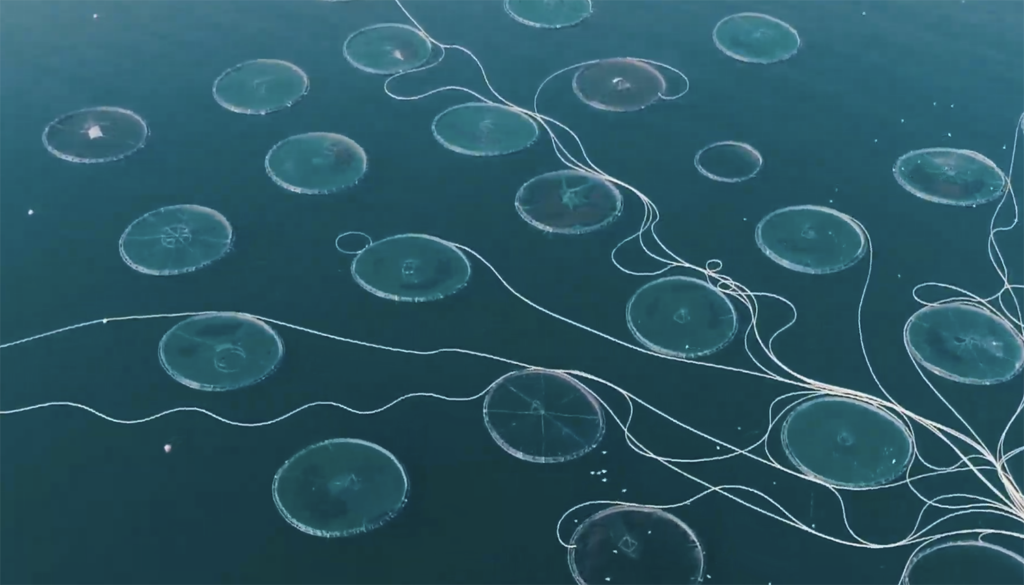

Spurred by oxygen and biodiversity depletion in its once-pristine waters, starting in 2020 the government of Chile mandated that ocean-based salmon farms report environmental data from both inside and outside fish pens, in real time. The country’s fish farms are now required to send information about temperature, salinity and dissolved oxygen levels directly to the country’s environmental agencies. The hope: a more ecologically responsible aquaculture industry.

Concerns about the ways aquaculture can stress environments may compel other governments to act similarly.

“Western Canada just took away ocean farming permits because of the fear of environmental impact,” points out Brandon Witte, CEO of Sightline Systems, an aquaculture data monitoring company. Sightline is currently piloting an AI-based system with two Chilean aquaculture farms in the hopes of showing Chile and anyone else with a stake in the matter that “we can raise sustainable fish in a way that’s not detrimental to our oceans,” Witte says.

Measuring ocean temps and dissolved oxygen have been used for years to predict feed volumes for salmon. “But there’s a ton of other things that can play into this to make better models so we’re not overfeeding fish, which contributes to negative water quality,” adds Witte. “Happy fish are fast fish so … if they’re sluggish, something’s wrong. Can I use that in our modeling to understand which parameters are influencing their speed?”

He’s also looking at running historical data through forecasting models to guess, “What do we think temperature or pH or salinity is going to do?”

I can learn so much more from four sites than just one.

Sightline, though, is interested in going beyond these metrics to understand ocean health around fish pens more granularly. In its early years, Chile’s rapidly growing aquaculture industry used a preponderance of antibiotics as a preventative measure. Witte says his company’s tech is working out how to check for such drug presence in the water.

“AI can help [give] early warnings of an algal bloom, using pixel analysis to look for [its] signature and using algorithms based on the volume identified in the samples to determine if it’s increasing or decreasing,” he says. Keeping an eye on biomass size is another way to quality control: “Can we use the camera to identify the volume of fish” in a pen, moving some as necessary?

But thwarting efforts to improve the industry in these ways is secrecy. “I can learn so much more from four sites than just one and if I can exponentially gather information from corporations and get them to share this for the benefit of the industry by combining data – we haven’t gotten that buy-in,” says Witte.

Artificial intelligence is already helping improve fisheries, but the trick is in training the tech

AI for QC

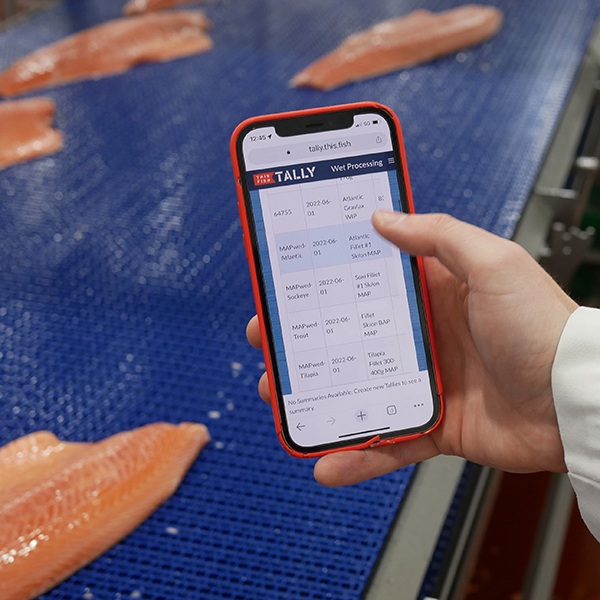

On the opposite end of the seafood spectrum, Eric Enno Tamm’s Vancouver-based ThisFish is working to improve efficiency and quality at the processor level.

“Farmers really don’t know what their production yields and quality are until they process their [seafood],” Tamm says. “It’s not until you start to cut up and fillet a fish that you start to see defects and other quality issues … and with shrimp, around kind of size and coloration. Our long-term vision is to link farms with factories to get [this] very detailed data.”

Tamm hopes that building data sets that help predict what farm practices are affecting fish quality will help mitigate low yields and therefore waste as a way to improve overall sustainability.

“But we’re not there yet,” he says.

With technology he’s been experimenting with, video cameras take photos of every fillet coming across the line inside a lightbox, which blocks out glare from overhead fluorescent lighting hitting wet fish to make for an easier-to-analyze image. The filets are classified according to seven types of defects, such as gaping and bruising. Data would be collected year over year and at some point, when yields are shown to have dropped, say, it would sent back to the farm to determine what practices and conditions might have led to that yield drop.

For example, “There’s a day shift and a night shift and actually what you might find is that most of the bruising is happening on the night shift,” Tamm says. “Maybe there’s a production manager that’s a lot more cavalier about quality and lets his workers step on the fish more. You try to correlate the data with the outcome and try to tease out the root cause of the quality problems.”

Possibly even more consequentially, he believes that building up these sorts of data sets and analyzing them for trends might help to solve for fraud in the seafood industry, alerting suppliers to product that has not been sustainably produced, for example.

“Let’s say you have a really good supplier that sells you fish and the data predicts that you’ll have good outcomes from this purchase – but it turned out really bad,” Tamm says. “Maybe the fish you got was purchased from another supplier and passed on to you.”

Tamm says the United States Food and Drug Administration, which oversees all U.S. seafood imports, is already starting to use machine learning to flag these sorts of issues with imported fish. But over time, he says, “We’ll be able to do that at an enterprise level.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lela Nargi

Lela Nargi is a Brooklyn, N.Y.-based veteran freelance journalist covering the food system, social justice issues, science/environment, and the places where those topics intersect for The Guardian, Civil Eats, City Monitor, JSTOR Daily, Sierra, Hakai, and Ensia, among other outlets; she’s currently contributing writer for The Counter. You can find her at lelanargi.com and on Twitter @LelaNargi.

Tagged With

Related Posts

Innovation & Investment

AI platform delivers data to fish and shrimp farmers

XpertSea does more than count fish. It uses AI and computer vision to calculate growth rates and optimal harvest dates to improve aquaculture efficiency.

Innovation & Investment

Apps, AI and algae: Meet Hatch Blue’s fourth cohort

Hatch Blue’s fourth cohort performed their pitches online for the first time, showcasing a spectrum of aquaculture product and service businesses.

Intelligence

Aquaculture research projects receive $1.3 million to explore imaging technology and AI

Three aquaculture research projects have received a combined $1.3 million to explore imaging technology and artificial intelligence (AI).

Innovation & Investment

Can aquaculture go all-in on AI?

Progressive aquaculture companies are harnessing the power of artificial intelligence (AI) from firms like Umitron and Aquaconnect to improve operations.