Researchers inch closer to solving the biological mysteries of a species important to Japanese cuisine and culture

Last October, Kindai University in Japan became the country’s first to successfully rear Japanese eels (Anguilla japonica) by hatching larvae from older specimens that were also farmed at the university.

Eel farming depends on juveniles, or fry, that are caught in the wild, but with numbers declining significantly and a heightened interest in Japan in eel conservation efforts, hopes are high that the institute’s latest work can be put to practical use, leading to the commercial production of an essential ingredient in Japanese food culture.

“The Japanese consume approximately 50,000 tons of eel every year,” Professor Hideki Tanaka at Kindai University’s Aquaculture Research Institute told the Advocate. “Many people believe that the university’s efforts to farm eel are important steps to safeguard declining numbers in the wild. Eel is a staple in traditional Japanese cuisine and has been a healthy and luxurious food for hundreds of years. We hope that one day our work will contribute greatly to meeting the demand for this important species.”

Kindai’s research into Japanese eels goes back to 1976 when studies on eel larvae production began. In 1984 and 1989, eggs were successfully collected and hatched, but because the larvae wouldn’t eat, research was subsequently discontinued. It was then restarted in March 2019 based on the methods of the state-run Japan Fisheries Research and Education Agency, which in 2010 became the world’s first facility to achieve full-cycle aquaculture of eels.

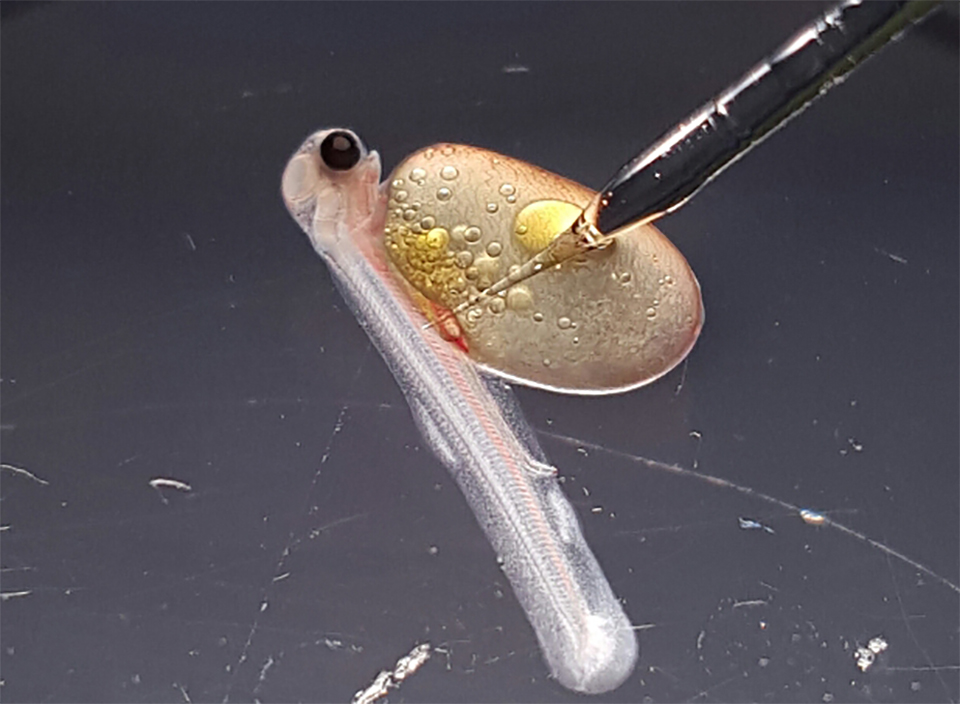

In September 2019, Kindai successfully obtained eel fry, or leptocephali, but unfortunately these didn’t survive. It was not until March 2021, when juveniles, known as glass eels, were obtained for the first time at Kindai. From these, larvae subsequently hatched in 2023.

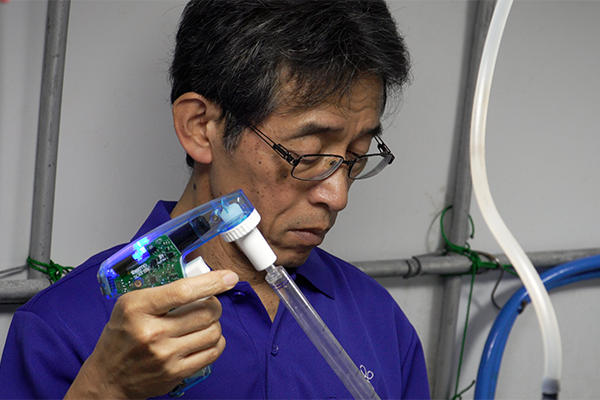

The glass eels were matured artificially through the administration of hormones to form eggs and sperm (in captivity, eels do not produce or secrete the hormones involved in maturation and as a result, do not reach sexual maturity). On July 5, 2023, fertilized eggs were removed and the larvae hatched the following day. They will metamorphose into glass eels in about five to 10 months, while it will take another year or more to reach adult sizes.

“Our major task is to supply a usable amount of glass eels for commercial-scale production at the lowest possible cost,” said Tanaka. “Glass eels that are obtained from full-cycle aquaculture are unique in that they do not place any burden on numbers in the wild. However, it will also be advantageous if they are less susceptible to disease, taste good and quickly grow into adults.”

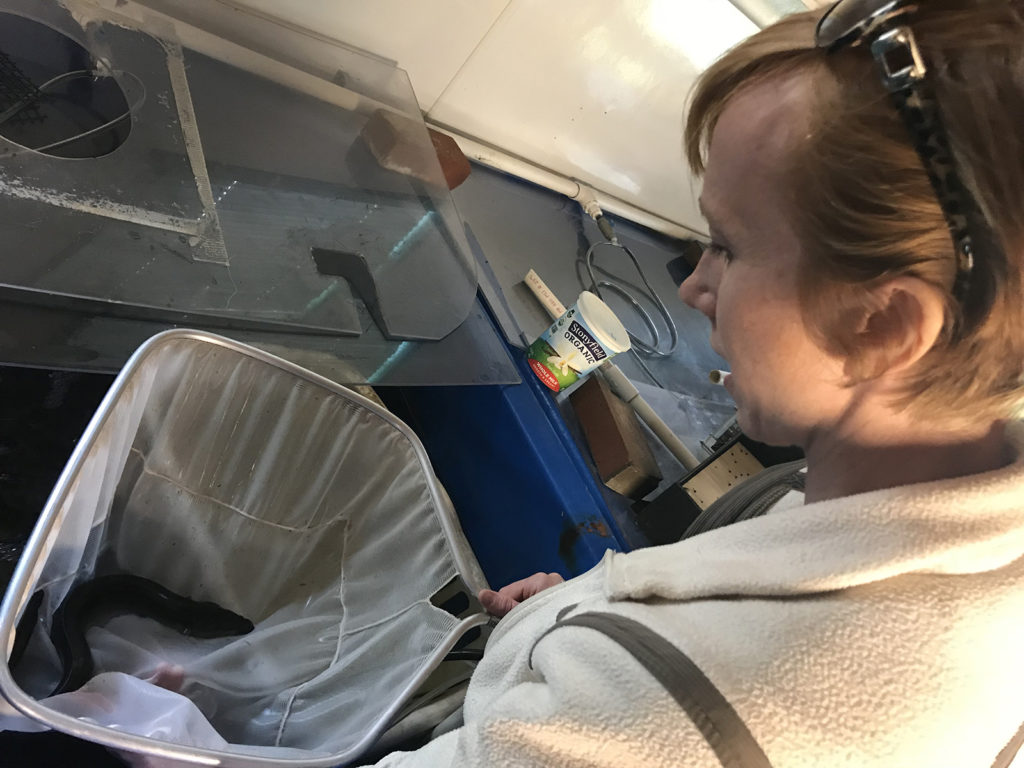

Kindai has struggled to sustain a large population of young eels due to the many mysteries surrounding their biology. By far, the hardest challenge has been obtaining fertilized eggs and turning them into glass eels. In addition, the technology that is currently used to farm eel larvae can only be used in small tanks, and increasing their size and numbers will not be enough to achieve large-scale production. This means that today, there is no prospect of mass-producing glass eels at a low cost. Going forward, Kindai plans to address the challenges by focusing on developing production technology that could help in the mass production of glass eels and improving feed.

“Glass eels are fed with a slurry-type diet that is made from enzyme-treated fishmeal, dairy products and chicken egg yolk, all of which are easily digested and absorbed,” said Tanaka. “In order to improve feed, we will need to review each raw material while paying attention to physical properties. We will also need to change blending ratios and conduct breeding tests to repeatedly evaluate parameters such as survival rate, growth and larvae health.”

“The most difficult issue for us is time constraints,” Tanaka continued. “It takes a certain number of years for the fry to grow to maturity and for the next generation to be produced and it’s difficult to reduce this time just through research. There are also a number of issues that remain from four years ago, including egg collection, hatching and larval rearing. These processes are still not stable.”

However, because the university has successfully achieved the full-cycle aquaculture of other species, such as bluefin tuna, achieving the same with Japanese eel has raised hopes for the early commercialization of the species. Tanaka’s next steps will be to improve rearing technology for more stable egg collection, hatching and larval rearing. He believes that one day in the future, Kindai’s methods will be used for commercial purposes.

“There are limitations, and it will not be easy for us to immediately produce all the glass eels that are needed for aquaculture at a low cost,” he said. “Nevertheless, the day will come when it will be possible to produce them, not just at a lower cost but also in larger quantities than today.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Bonnie Waycott

Correspondent Bonnie Waycott became interested in marine life after learning to snorkel on the Sea of Japan coast near her mother’s hometown. She specializes in aquaculture and fisheries with a particular focus on Japan, and has a keen interest in Tohoku’s aquaculture recovery following the 2011 Great East Japan Earthquake and Tsunami.

Related Posts

Innovation & Investment

American Unagi brings eel farming back ‘home’

Sara Rademaker launched American Unagi to shift eel farming to American soil, where the eels are from. Why? Because of the novelty, and because she saw an opportunity to do things better.

Responsibility

In Japan, aquaculture is deployed in the defense of endangered species

Tokyo University researchers have learned to spawn fish from germline stem cells in vitro, a method that can be deployed to help endangered species.

Health & Welfare

Japanese eels: Progress in breeding and nutrition

The Japanese eel (Anguilla japonica) is cultured in ponds in Japan, China, the Republic of Korea and other countries. Ongoing research is addressing knowledge gaps in the domestication, controlled breeding and nutritional requirements of the species.

Innovation & Investment

Tuna aquaculture: Fishing for progress

Aquaculture could be a sustainable alternative to fishing for tuna but achieving commercial-scale production has proven challenging.