Sponsored post: Vision-based shrimp grader is radically changing how shrimp processors do business

Years ago, Laitram Machinery, a global leader in high-performance shrimp processing equipment, set out to upend a common misnomer in shrimp processing — that, despite an increasingly competitive environment whereby shrimp processors are continually scratching for new ways to drive efficiency and reduce costs while improving product quality, there was little room for innovation in shrimp grading.

“After traveling and meeting with hundreds of processors in countries like India, Indonesia, Thailand and Vietnam, we noticed that there is often an initial belief among shrimp processors that there is very little room for improvement in their current grading operation and that is why shrimp grading, though a critical process, has seen little innovation in the last 40 years,” said Jitendra Pandya, Laitram Machinery’s Asia-Pacific business manager.

Currently, dimensional roller grading is one of the more common methods used for large-scale production. As raw material moves through these graders, the product is sorted using only the widest section of the shrimp as a reference, not considering the entire length, height, and shape of the shrimp, which can result in inconsistent measurement and grading. When large shrimp are misgraded into lower-priced size categories, their selling price drops. Also reducing efficiency and profitability are the cost of manual labor, high uniformity ratios (dividing the weight of large shrimp by the weight of small shrimp), the lack of real-time data, and frequent regrading of poorly graded products.

However, Laitram Machinery’s persistence has paid off. The U.S.-based company has developed the SMART Sorter — a vision-based shrimp grader that’s radically changing how shrimp processors do business, resulting in an immediate competitive advantage.

“We spent several years and made a considerable investment in developing a reliable, vision-based grading system that would once again revolutionize the shrimp industry,” said James Lapeyre, General Manager of Laitram Machinery.

A multidisciplinary team comprised of innovators in mechanical engineering, artificial intelligence, mathematics, vision recognition, and programming worked together at Laitram Machinery to tackle the technical challenges to accomplish this task.

Some of the challenges were related to a technique called “singulation” that adequately separates shrimp for both imaging and ejection with a pneumatic valve. The team at Laitram Machinery spent time working on how to distinguish two shrimp overlapping, which it calls a “shrimp clump,” from one large shrimp. Compared to previous technologies, this system relies heavily on a user-friendly interface. Laitram Machinery spent considerable time and resources in the programming and design of the controls, remote access, and calibration method.

Finally, Laitram Machinery knew that one of its biggest challenges would be to prove the performance on a wide range of shrimp sizes and freshness levels, and to prove the reliability of such a new system in remote and logistically challenging environments. The company’s global service team played a key role in the installation, training, and support of its customers, especially with its early adopters.

The SMART Sorter comes to fruition

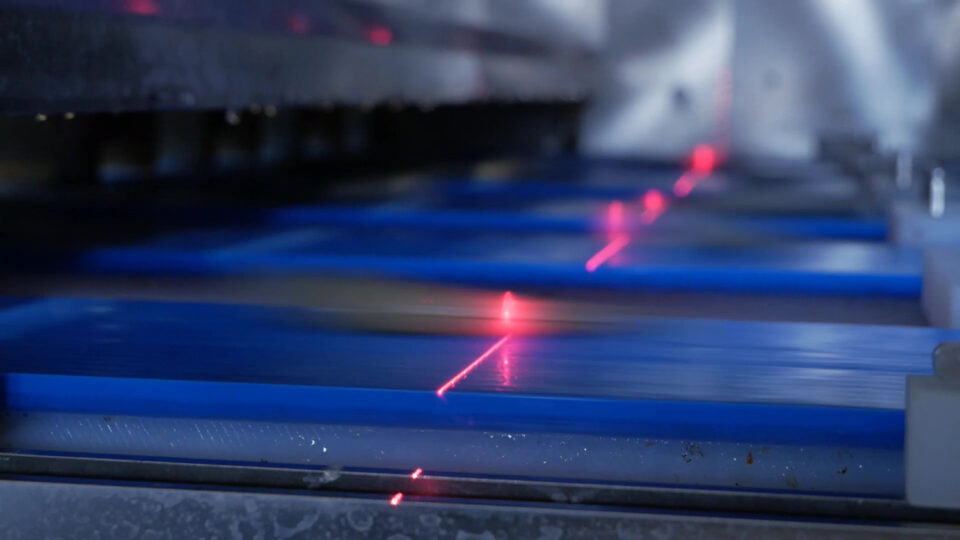

The SMART Sorter Shrimp Grader is a patented, automatically fed grader that individually images each shrimp in a lot. The Smart Sorter uses laser imaging and computer-vision algorithms to inspect, grade and sort shrimp in various product presentations, including HLSO, HOSO and PUD.

The SMART Sorter has three main stages: singulation, imaging and ejection.

In the singulation stage, a high-speed flow of individually separated shrimp is transported to six parallel conveyors into the imaging stage.

The imaging stage incorporates six laser profile scanners, which produce a laser reference line across each conveyor. The SMART Sorter scans each shrimp in a lot to determine its volume. The scanned volume is then converted to weight applying a volume to weight calibration function. Image processing algorithms inspect each image for broken shrimp and clumps of shrimp that may not have been adequately singulated. Shrimp clumped together on the conveyor, thereby unable to have the individual shrimp accurately imaged, are conveyed back to the feed tank to be reimaged and sorted.

The ejection stage consists of a series of air jets used to eject each shrimp off the conveyor into the appropriate bin, based on the selected weight grade. The ejection system has been designed to accurately and reliably eject shrimp with no damage.

Various configurations are available to fit the exact product flow and layout constraints of different processors.

One of the most significant features of the SMART Sorter is the access to real-time sorting data. The touch screen control panel provides an intuitive and easy-to-use data window that enables data-driven plant optimization. Batch-by-batch, source-by-source, and day-by-day data logging of grading data allow the processor to make better decisions regarding buying, selling and sorting shrimp.

The SMART Sorter effectively eliminates misgrading and ensures each shrimp is sorted into the most valuable product with unmatched speed and accuracy, regardless of a processor’s grading strategy, thus maximizing the value of each sorting batch.

The system is designed to be upgraded and to continue getting smarter with new features, such as a SMART Portal data analysis system to track and monitor machine performance remotely. Service plan and optimization-audit services are available to ensure maximum uptime and optimal operation, allowing processors to extract maximum value from their Smart Sorter investment.

The SMART Sorter is now a proven technology, with more than 60 systems placed globally, said Lapeyre. Many processors are repeat customers, running multiple SMART Sorters, because they immediately understand the system’s value and competitive advantage. Customers include:

Wellcome Fisheries, India: “We no longer run our roller graders. It eliminates regrading, and the real-time data helps up to purchase product and operate our factory.”

Tai Kim Anh, Vietnam: “With the SMART Sorter, I can produce everything I did before but now I am doing it faster, at higher quality, with better process yield, all while cutting my grading staff by 70 percent.”

Soc Trang Seafood (Stapimex): “The SMART Sorter gives more control over the grading data and more flexibility to grading strategies. We were so satisfied with this machine, and we decided to invest two additional SMART Sorters.”

Thai Union, Thailand: “After seeing the first two machines run, we knew that we had made the right decision, and rush-ordered a fifth machine.”

Processors using the Smart Sorter are seeing savings of U.S. $0.07 to $0.15 per pound, according to Lapeyre. Assuming an annual production of 10 million pounds per year, the savings range from $700,000 to $1,500,000, generating an investment payback of six to 12 months.

“This proven and patented technology continues to break all traditional standards for shrimp grading, and thanks to the shrimp industry’s commitment to innovation, Laitram Machinery will continue to improve and bring new features to making the SMART Sorter smarter,” said Lapeyre.

To learn more about the SMART Sorter, read case studies or organize a visit to its pilot facility to demo the SMART Sorter, visit www.laitrammachinery.com.

Author

-

Laitram Machinery

This article, from our sponsors at Laitram Machinery, was created by Karen Quaas, marketing manager, and Chuck Ledet, consultant and product manager for the SMART product line.

[109,111,99,46,109,97,114,116,105,97,108,64,115,97,97,117,81,46,110,101,114,97,75]