Shrimp feed additives from Adisseo support biomass and profitability while answering consumer expectations

The year 2022 witnessed a growing number of headlining natural disasters associated with climate change, such as the record-breaking forest fires in Europe during summer, or the catastrophic floods that hit Pakistan in the fall. United Nations directly pointed the finger at wealthier nations for their impact on climate change that contributed to these catastrophes.

At the same time, global climate change has come to the forefront of environmental considerations that preoccupy consumers. Efforts are well underway among European aquafeed manufacturers to implement carbon labeling to their feeds. A strategy has been to reduce or eliminate from their formulations Amazon-origin soybean meal that had gained a bad reputation among European consumers due to its link to deforestation.

Life Cycle Assessment (LCA) is a comprehensive tool to measure the environmental impact of products or services during their entire life cycle. Regarding functional feed additives in shrimp farming, LCA seeks to measure their environmental impact, i.e. such as on land use, water use, or eutrophication, along upstream (e.g., raw material extraction, supply chain and manufacturing) and downstream (eg. transport, feed production, farm resources and emissions, farm productivity, packaging, etc.) processes. Such exercise requires a large amount of data and variables that need to be collected across the value chain of the additive.

Today, the industry can rely on a handful of public databases (e.g, GFLI, Agrifootprint) that can provide reliable reference values for such exercises, and there are few LCA studies focused on shrimp farming. Even though, more industries are progressively moving towards conducting such LCAs, as consumers become increasingly aware of their significance, while retailers demand footprint from their suppliers in response to these customer pressures. It is therefore a question of time before shrimp farming needs to embark on such routine assessments to satisfy customer expectations.

Adisseo is a leading producer of health and nutritional additives that help make aquaculture production more efficient and sustainable. With the ambition to reduce the environmental impact of aquaculture, Adisseo initiated an exercise to measure the potential of functional feed additives to reduce the environmental footprint of shrimp farming.

A health-promoting additive to increase biomass and reduce the carbon footprint of shrimp production

Sanacore®GM is a phytobiotic additive with broad spectrum action as well as a long history of cost-efficient and successful use in shrimp farms facing common diseases such as Vibriosis, AHPND, EHP and White Feces Syndrome (WFS).

The LCA was conducted on a large corporate shrimp farm in the region of Batasana (Indonesia). This farm had experienced several successive bad crops affected by WFS, EHP and WSSV, with yields dropping from the targeted 10 MT/ha to just above 5 MT/ha. Sanacore®GM was supplemented in feed as a preventive strategy to improve survival and biomass under expected disease outbreaks. Farm productivity and CO2 production of the present crop was compared with standard farm productivity of previous crops.

As expected, the ponds tested positive to EHP and symptoms associated with an outbreak of WFS were observed. Remarkably, ponds supplemented with Sanacore®GM resulted in improved survival (3×), biomass (+65%), and FCR (-32%). Such improvements in productivity were reflected in a positive impact on the environmental footprint.

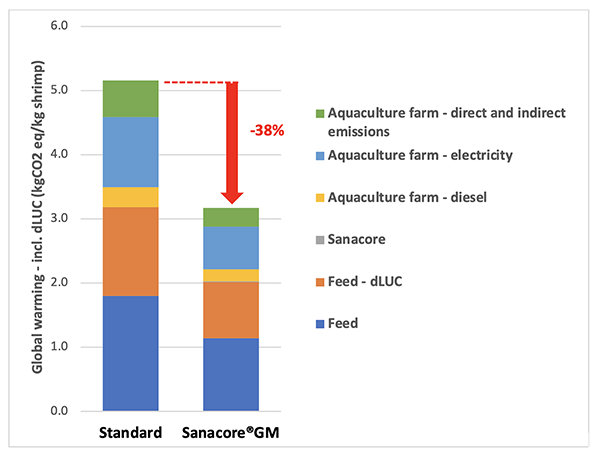

Fig. 1 shows an overall 38% reduction in greenhouse gas (GHG) emissions per kg of shrimp produced, expressed as kg CO2 equivalent, resulting from the additive supplementation. An estimated 6.2 kg CO2 eq/kg shrimp were on average generated in previous crops, as the main causes of the carbon footprint were feed, energy consumption, and direct and indirect emissions at the farm. Sanacore®GM reduced the overall carbon footprint to 3.7 kg CO2 eq/kg shrimp by reducing the CO2 contributions of all sources through improved production efficiency. This LCA, therefore, confirmed the positive contribution of the preventive application of Sanacore®GM s to reducing the carbon footprint of shrimp farming in conditions under high disease pressure.

A digestive enhancer to reduce both feed cost and the carbon footprint of shrimp production

Aqualyso® is a lysophospholipid-based digestive enhancer aiming to improve nutrient digestion and utilization under feed cost reduction strategies. The additive can be used to boost growth and reduce FCR in shrimp feed while reducing fat levels in the diet. In the present LCA, experimental data obtained from a replacement strategy based on 0.75% lecithin and 0.5% fish oil replaced by the additive was modeled along with representative farm data.

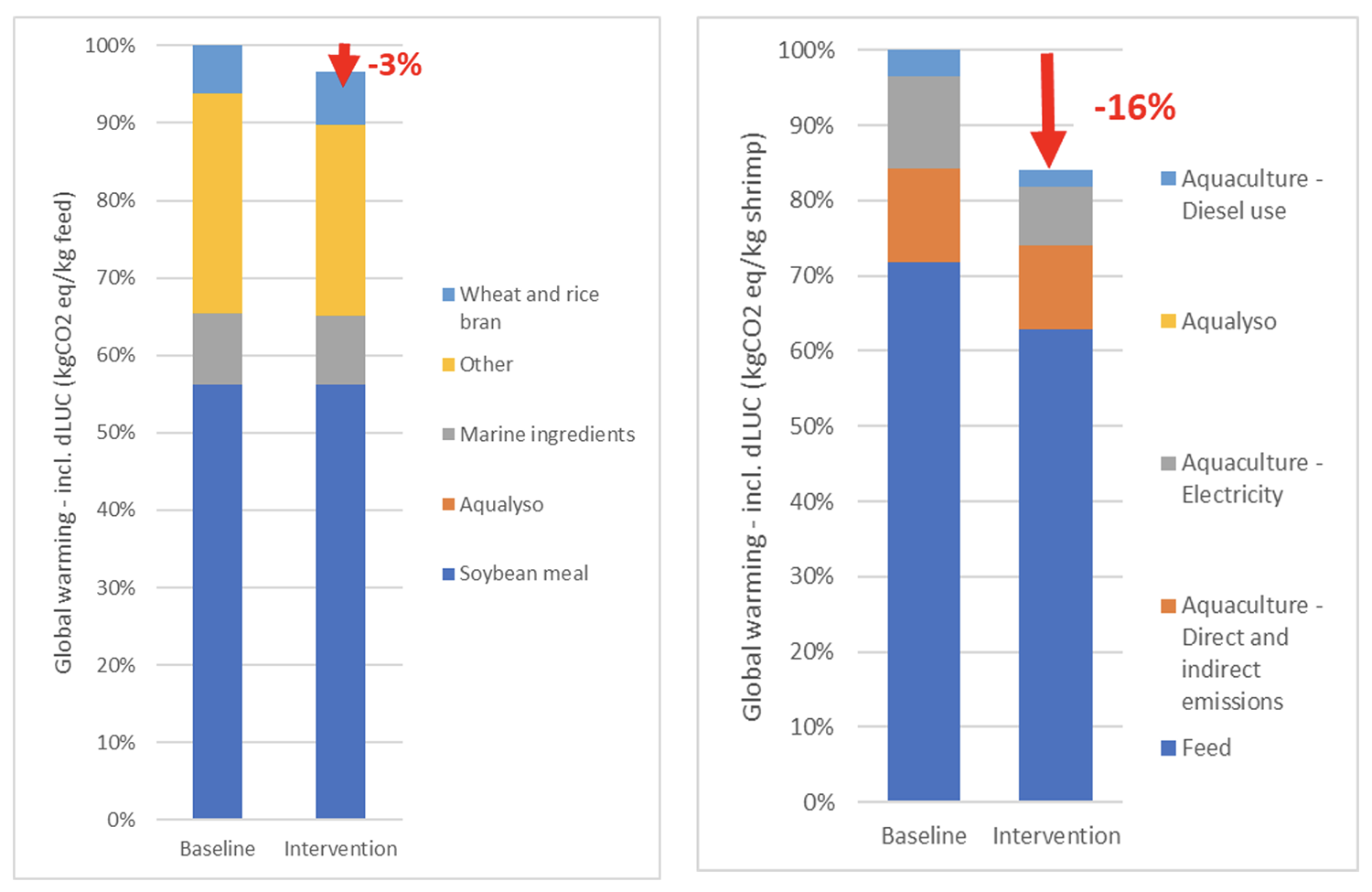

Aqualyso® supplementation reduced feed cost while supporting feed performance. Growth and FCR were improved by 13% and 9%, respectively, in relation to the high lecithin and fish oil feed. The major contributor to the carbon footprint of feed was soy usage, mostly through Land Use Change (i.e. deforestation) and representing 55% of the feed total CO2 emissions (Fig. 2A). The carbon footprint reduction in feed attributed to the reformulation (i.e. lecithin and fish oil replacement by Aqualyso®) was 3% and thus considered only marginal (Fig. 2A).

On the other hand, the impact of the additive supplementation on growth and FCR led to a more significant reduction of 16% in the overall CO2 production per kg of shrimp produced (Fig. 2B). This second LCA further supports the potential of effective nutritional feed additives to not only improve feed performance or cost-effectiveness but also contribute to reducing the global warming impact of shrimp production.

The UNEP Emission Gas Report 2022 projected that by 2030 and with the current policies, GHG emissions will rise 13.7 above 2010 levels (from 51 to 58 kg GtCO2e). This increase represents a hurdle to reaching the Paris Climate Agreement’s goal of limiting global temperature rise to 1.5oC by the end of the century. This means that a systemic effort from all stakeholders needs to urgently take place to reduce GHG emissions at a global level and it puts increased pressure on all industries, including the aquaculture industry, to contribute to this reduction effort.

The two examples above show that health and digestion programs based on effective functional feed additives such as Sanacore®GM and Aqualyso®, respectively, can be used by the shrimp industry as tools to support biomass and profitability but also to address these efforts while also answering consumer expectations.

Author

-

Adisseo

This article was prepared for Adisseo by Martin J.M. Guérin, Amel Hocini and Waldo G. Nuez-Ortín of Adisseo, France; and Björn Kok, University of Stirling, Scotland, and Blonk.

Tagged With

Related Posts

From Our Sponsors

Aquafeed additive from Adisseo can reduce the impact of bacterial diseases for fish and shrimp

In aquaculture trials with Pacific white shrimp and Nile tilapia, Bacti-nil® Aqua, an aquafeed additive from Adisseo, effectively prevented disease and promoted growth.

From Our Sponsors

Fish diseases hinder aquaculture growth and threaten global food security. Could this feed technology help secure the sector?

APEX® BRANCHIA – a functional feed additive from Adisseo – can reduce the impact of fish diseases and promote fish productivity and survival.