Significantly higher oil yields are possible if the raw materials are stored for one day or longer

Norway is the second-largest fish producer in the world at almost 3.8 million tons of seafood in 2021, including both fisheries and aquaculture. Although the purpose of the seafood producers is to generate food, around 1.1 million tons (29 percent) was categorized as residual raw material. This raw material often gets lost early in the value chain or is underutilized to produce lower value products for feed, biogas or energy application.

The most significant losses are generated on board the deep-sea vessels, where 70 percent of the residual raw material was discarded at sea in 2021. This part of the fishing fleet includes the largest vessels, mainly freezing trawlers and autoline vessels, which are out fishing for long periods far from shore. These vessels mainly produce headed and gutted (HG) whitefish with the most important species being Atlantic cod (Gadus morhua), saithe (Pollachius virens) and haddock (Melanogrammus aeglefinus).

The residual raw materials generated on board are mainly viscera (including all inner fractions: liver, gonad, stomach and intestines) and heads. The viscera, especially the liver, are rich in the healthful long-chain omega-3 polyunsaturated fatty acids (PUFA) eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA), which can be utilized to produce ingredients for human consumption. However, these materials are exposed to fast quality degradation due to oxidation, enzymatic and microbial processes that start just a short time after harvest.

To produce high-quality ingredients from these raw materials, optimal handling and processing strategies are needed. There is a current knowledge gap on when to process the raw material as no published experiments have investigated the quality status and development in oil produced from cod residuals at an early stage on board these large seagoing vessels. In addition, knowledge on the effect of an out-sorting of the liver compared to oil production from the whole viscera fraction is missing.

This article summarizes the original publication [Meidell, L.S. et al. 2023. Upgrading Marine Oils from Cod (Gadus morhua) On-Board the Deep-Sea Vessels – From Waste to Value. Foods 2023 12(8), 1659] of a study that investigated the effect of raw material freshness and sorting on the quality, composition and yield of oil produced thermally from Atlantic cod residuals on board a commercial trawler.

Study setup

The study was conducted on-board a commercial freezer trawler to enable oil production from whole viscera fractions and out-sorted livers immediately after a catch and during a storage period for up to six days at 4 degrees-C. The yields of produced oil and emulsion were calculated and the composition of the oil was analyzed by determination of fatty acid composition and distribution of lipid classes. To evaluate the quality of the oils, the content of free fatty acids and the amount of primary and secondary oxidation products were determined. For detailed information on the materials and methods, refer to the original study.

Gaps in the conservation status of the most important fished species of marine fish

Results and discussion

Regarding the raw material composition and yield of produced oil, analysis of the biochemical composition of fresh raw material showed that viscera contained 57.3 ± 8.5 percent water, 21.8 ± 2.9 percent lipids, 12.5 ± 0.3 percent protein and 1.0 ± 0.2 percent ash, while liver contained 30.7 ± 3.0 percent water, 64.7 ± 1.5 percent lipids, 6.9 ± 0.3 percent protein and 0.6 ± 0.1 percent ash. The composition of viscera was similar to what has been reported by other researchers, and the results were also in accordance with what was reported for Atlantic cod caught in the North Sea in the same season and with similar fish length as the present study However, there can be large variations in the biochemical composition of cod viscera and liver due to seasonal variations and factors such as diet, age and sex. It has been reported that the lipid content of cod liver can vary as much as 5 to 78 percent.

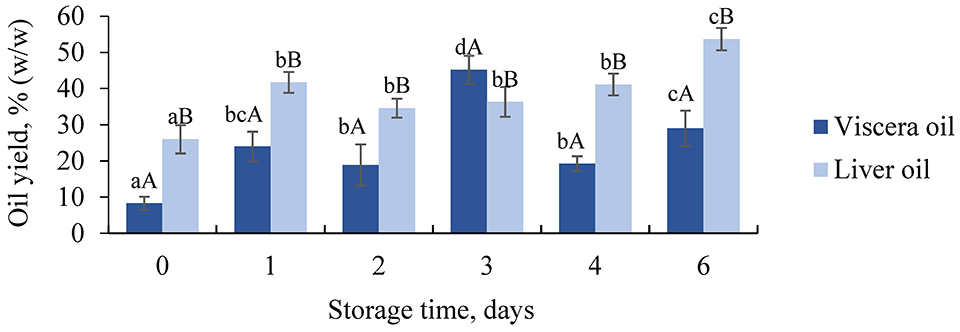

The yield of produced oil directly relates to the fisheries’ profits, so increased knowledge about how the raw material freshness influences the oil yield is of great interest to industry. The lowest oil yields were obtained when the fresh raw material was used with yields of 8.2 ± 1.8 percent (w/w) for viscera and 26.0 ± 3.9 percent (w/w) for liver at day 0 (Fig. 1). For both raw materials, the oil yields were significantly higher after storage for one to four or six days compared to fresh raw materials (day 0). For liver oil, the highest yield (53.7 ± 3.1 percent w/w) was produced on the last storage day (day 6). The results indicate that oil should be produced from raw material stored for more than one day to maximize the oil yield and that viscera should be stored for a maximum of three days to avoid the formation of an emulsion.

The dominating fatty acids in raw material and oil produced from viscera and liver were monounsaturated fatty acids (MUFA), followed by polyunsaturated fatty acids (PUFA) and saturated fatty acids (SFA). The viscera oils consisted of 50–55 percent MUFA, 26–28 percent PUFA and 19–22 percent SFA. This is in accordance with results reported by other researchers, where oil produced by enzymatic hydrolysis of Atlantic cod viscera (including liver) consisted of 54–56 percent MUFA, 24 percent PUFA and 20–22 percent SFA. In humans, intake of marine MUFA is reported to have protective effects against different lifestyle-related diseases. However, the most well-documented health effects are associated with the intake of the marine long-chain fatty acids PUFA EPA and DHA.

The average content of total omega-3 fatty acids accounted for 23.8 percent of all fatty acids in both raw materials (viscera and liver). The contents in oils produced during storage ranged from 22.4 to 23.5 percent for the viscera oils and from 20.3 to 24.2 percent for oils produced from out-sorted livers. Fish oil typically contains between 10 to 35 percent omega-3 fatty acids, indicating that the produced oils are good sources of these valuable fatty acids. The fatty acid composition in the liver of cod is affected by factors such as diet, seasonal variations, and reproductive status. The fish used in the experiment was caught in the spawning period (January to April), which might explain the slightly lower DHA contents found in the present study.

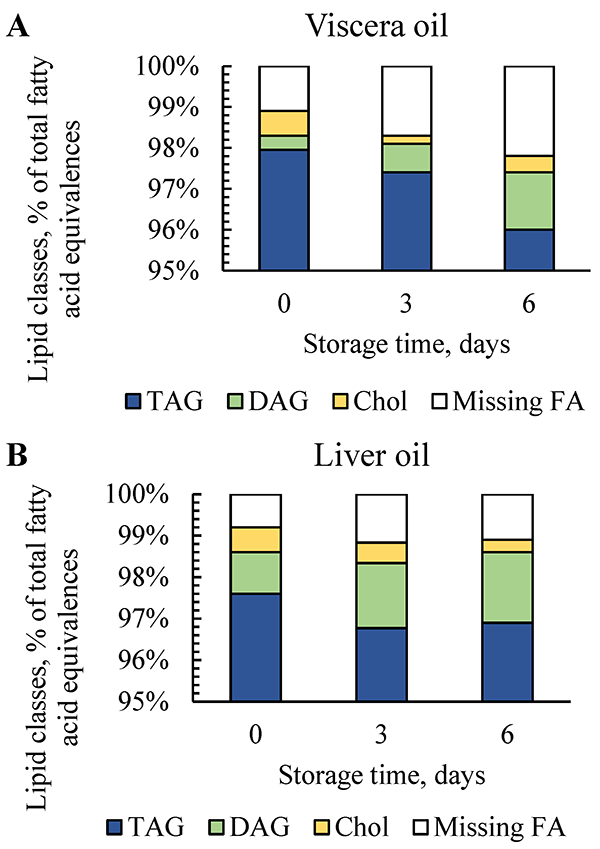

Results also provided information about the lipid classes (percent of total fatty acid equivalences), which were determined in oils produced at days 0, 3 and 6, where signals appeared in the region of triacylglycerols (TAG), diacylglycerols (DAG) and cholesterol (Chol) (Fig. 2).

Viscera oil produced from fresh raw material (day 0) contained 98.0 percent TAG, 0.4 percent DAG and 0.6 percent Chol. Liver oil made of fresh liver contained 97.6 percent TAG, 1.0 percent DAG and 0.6 percent Chol. This is in accordance with other previous studies. The higher amount of DAG in liver oils compared to viscera oils on all days (days 0, 3 and 6) is most likely due to the higher concentration of lipases in cod liver compared to viscera, resulting in lipolysis of TAG into DAG and free fatty acids (FFA).

Longer storage led to slightly lower contents of Chol in both viscera oil (0.6 percent at day 0, 0.2 and 0.4 percent at days 3 and 6) and liver oil (0.6 percent at day 0, 0.5 and 0.3 percent at days 3 and 6). This has been observed in previous studies during the storage of whole fish and residuals from cod and saithe, where the decrease was explained by the increased content of cholesteryl esters formed by Chol and FFA. Overall, the results indicate that the composition of lipid classes was affected by both raw material freshness and sorting.

Perspectives

Results of this study indicate that storage of viscera and liver can be considered to increase the yield of produced oil. Significantly higher yields were obtained when the raw materials were stored for one day or longer at 4 degrees-C prior to processing. However, storage of viscera for longer than three days would not be recommended as undesired emulsion was formed, resulting in decreased oil yields. The fatty acid composition did not seem to be affected by the raw material freshness, and oil produced from both raw materials was rich in the health beneficial omega-3 fatty acids EPA and DHA.

Oil produced a short time after the catch led to higher TAG contents and lower FFA contents compared to oil produced from stored raw materials. Use of the whole viscera fraction resulted in oil with significantly higher FFA contents compared to liver oils on the first days of storage (days 0–3), but high-quality oil could be produced from both raw materials even after two days of storage, according to quality guidelines.

The amount of oxidation products was affected by both raw material freshness and sorting. The use of the whole viscera fraction led to higher oxidation in four of the six storage days. Based on quality recommendations, high-quality oil acceptable for food applications was produced even after three days of storage of the viscera and during the whole storage period for the liver.

Generally, the results indicate that the raw materials should be processed a short time after the catch to optimize the oil quality, especially when utilizing the viscera. However, storage of the raw material for one to two days at 4 degrees-C can be considered to meet both process and quality parameters important for the industry. Although out-sorting of the liver led to oil with higher quality, utilization of the whole viscera fraction should be considered as oil of high quality could be obtained, and this will increase the availability of raw material on-board and be a less resource-demanding procedure. However, potentially high bacteria contents in the viscera could be a limiting factor that should be investigated in future studies. This would be especially important considering the utilization of the remaining protein fraction after oil extraction.

Overall, these results can be used as a knowledge base for decision-makers on when to process and how to upgrade highly degradable raw materials into high-quality food ingredients on board the deep-sea vessels.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Line Skontorp Meidell

Corresponding author and Ph.D. candidate

Department of Biotechnology and Food Science, Norwegian University of Science and Technology (NTNU), 7012 Trondheim, Norway[111,110,46,117,110,116,110,64,108,108,101,100,105,101,109,46,115,46,101,110,105,108]

Tagged With

Related Posts

Health & Welfare

Atlantic cod genomics and broodstock development project

The Atlantic Cod Genomics and Broodstock Development Project has expanded the gene-related resources for the species in Canada.

Fisheries

Distinct stocks of Atlantic cod face different climate change challenges

Distinct stocks of North Atlantic cod are being stressed by different factors of varying management severity due to the impacts of climate change.

Aquafeeds

A primer on sustainable feeds: Improving aquafeeds for sustainability, fish welfare and human nutrition

Improving aquafeed formulations can augment the sustainability and efficiency of aquaculture production – a new series from the GAIN project.

Health & Welfare

Photoperiod regulation inhibits spawning, promotes growth in Atlantic cod

Research has shown that an extended photoperiod for Atlantic cod females leads to reduced gonadal growth, faster body growth and shorter grow-out production periods.