Cawthron researchers led international effort to produce safe anesthetic

Scientists in New Zealand are cultivating the toxic microalga Alexandrium pacificum — best known for producing harmful algal bloom toxins — to explore its potential as a source of powerful pain-relieving compounds.

Led by the Cawthron Institute in Nelson, the research is part of an international project with Boston Children’s Hospital, Harvard Medical School, and U.S. biotechnology company AlgavitaBio. The goal is to produce a new anesthetic that could eliminate or significantly reduce the need for post-operative pain medication.

“The project began with scientists in the U.S. and South America trying to develop painkillers from marine toxins,” Johan Svenson, science impact manager at the Cawthron Institute, told the Advocate. “They struggled to access pure compounds, and we joined because we can produce these toxins in large quantities and high purity from microalgae. Our early work focused on toxins found in contaminated shellfish.”

Alexandrium pacificum was chosen as a suitable candidate because of its ability to produce what are known as saxitoxin analogs, or so-called sodium channel blockers, said Svenson. These compounds work to block ion channels – protein pores in cells that control key cellular functions by regulating ion flow. However, not all ion channels are the same, and not all compounds act indiscriminately. Some show a preference for certain channels over others, which opens the door to selective medical use. One such compound produced by Alexandrium pacificum is neosaxitoxin. This toxin works by blocking pain signals in sensory neurons. Research indicates that, when combined with commonly used agents adrenaline and the approved anesthetic bupivacaine, this synergistic combination may have the potential to provide rapid onset, regional anesthesia for surgery and extended analgesia for up to 72 hours of pain relief.

“We have several types of sodium channels in different tissues that control a range of vital functions,” said Svenson. “One particular subtype is involved in pain and blocking that one will hence block the sensation of pain.”

For more than two decades, efforts to develop a neosaxitoxin-based local anesthetic have been limited by a lack of commercially pure neosaxitoxin at scale. Now, however, the Cawthron team has found a workaround: Instead of isolating neosaxitoxin directly, they are extracting and isolating a more abundant compound called gonyautoxin 1&4 (GTX-1&4) from Alexandrium pacificum and converting it into neosaxitoxin in a single targeted step.

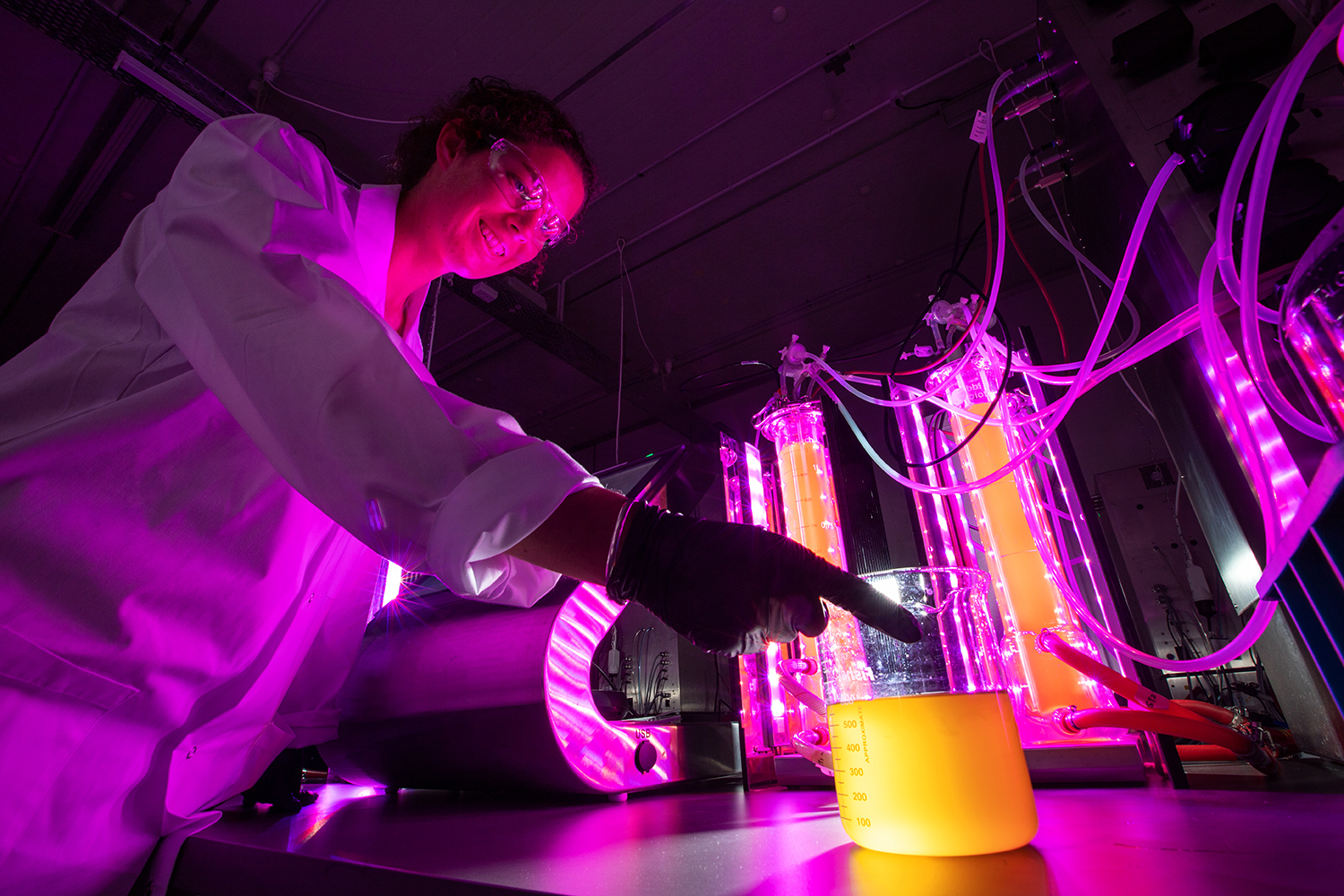

They are also growing Alexandrium pacificum in a custom artificial seawater solution prepared in-house. This makes large-scale production theoretically possible, provided Alexandrium pacificum can be reliably domesticated and cultivated at scale. The algae are grown in photobioreactors, said Svenson.

“These are big tanks, which are under strict control to allow for optimal growth and toxin production,” he said. “The toxins are then extracted from the harvested algal biomass using a set of chromatographic steps once the cells have been disrupted. Parameters such as light, temperature and nutrients are also important for both algae growth and toxin production. We get cell densities and yields of toxins that are higher than in normal algal blooms in the wild.”

Scaling up Alexandrium pacificum in artificial seawater and avoiding contamination and batchwise variability are challenging, Svenson noted, as it requires careful control of nutrients, growth conditions and the isolation of GTX-1&4. Still, this research has demonstrated a viable path to producing reliable, purified amounts of neosaxitoxin. While its timeline for general use remains uncertain, its development was reasonably advanced throughout clinical trials. One of the team’s reactors can generate around 25,000 doses of the drug lead in two weeks.

Feedback toward the research has been positive, especially from clinicians, said Svenson. Many see the project as addressing several urgent issues such as pain management and drug addiction – in particular because neosaxitoxin is highly potent and non-addictive. With phase one of the clinical trials now complete, Svenson and the rest of the team are now preparing for phase two and seeking international partners and investment.

No fluke: Cawthron Institute’s new web tool could help fish farmers tackle parasitic infection

Neosaxitoxin is intended solely for hospital use. It must be injected and administered alongside other compounds, so it won’t replace over-the-counter painkillers, but it could offer a transformative new option for pain relief. The team is also looking at the possibility of other applications, such as a range of applications developed for Botox beyond cosmetics, as well as veterinary medicine and animal health.

“We believe that neosaxitoxin will have a significant impact on pain management in future, making its development critical for human health,” said Svenson. “From a marine science perspective, it could become the first drug that is commercially produced from microalgae. We are now focused on either finding a partner or funding for the phase two trial, exploring additional uses for the compound, and looking into how other toxins and analogs could be used in the medical space. It’s an extremely exciting field of research.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Bonnie Waycott

Correspondent Bonnie Waycott became interested in marine life after learning to snorkel on the Sea of Japan coast near her mother’s hometown. She specializes in aquaculture and fisheries with a particular focus on Japan, and has a keen interest in Tohoku’s aquaculture recovery following the 2011 Great East Japan Earthquake and Tsunami.

Tagged With

Related Posts

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.

Innovation & Investment

Aquaculture Innovation Award Finalist: Seaqure labs’ aquafeed ingredient made from fungi and food waste

Sweden-based startup Seaqure labs is addressing global protein needs by exploiting the benefits of a mycoprotein powder made from fungi.

Innovation & Investment

‘Microbiome management’ gives RAS operator a foothold against off-flavor-causing geosmin

RAS operator puts proactive “microbiome management” approach in play to eliminate off-flavors and finds good results in lowering geosmin levels.

Innovation & Investment

‘Choices are limited when searching for alternatives to antibiotics’: How one veterinarian is employing bacteriophages to fight Vibriosis in shrimp farming

GOAL 2022: Bacteriophages can overcome antibiotics in aquaculture's fight against Vibriosis in shrimp farming, and Dr. C.R. Subhashini is leading that fight.