Falkenbergia rufolanosa can produce income for fish farmers

Most seaweed species that function as biofilters for finfish aquaculture have little market value, so produced biomass remains a by-product of biofiltration. This low value makes operation of these units economically difficult and is probably the key to today’s lack of industrial application of an otherwise highly feasible biofiltration method.

Most seaweed species that function as biofilters for finfish aquaculture have little market value, so produced biomass remains a by-product of biofiltration. This low value makes operation of these units economically difficult and is probably the key to today’s lack of industrial application of an otherwise highly feasible biofiltration method.

The main goal of a seaweed biofilter design should be the production of marketable biomass, which would then turn aquaculture effluent from a nuisance into a resource, and its biofiltration into a positive side effect.

Members of the marine plant ecology research group of the Center for Marine Sciences at the University of Algarve in Portugal have successfully established a commercially diverse seaweed biofilter using the tetrasporophyte of the red seaweed Asparagopsis armata. The plant is also referred to as Falkenbergia rufolanosa.

F. rufolanosa produces high levels of biologically active secondary metabolites. Among these compounds are natural antibiotic, antifungal, and anti-viral substances that are marketable for a wide range of applications in the fields of antifouling, cosmetics, and medicine.

Experimental system

In research financed by the E.U. SEAPURA project and protected by a French patent, the authors recently concluded a study to evaluate the feasibility of effluent-integrated or multitrophic-level production of Falkenbergia with emphasis on seaweed yield and biofiltration. The results were used in the design of a model for the treatment of the daily wastewater stream from commercially reared gilthead sea bream, Sparus aurata. These calculations incorporated a variation of the available surface area for the biofilter.

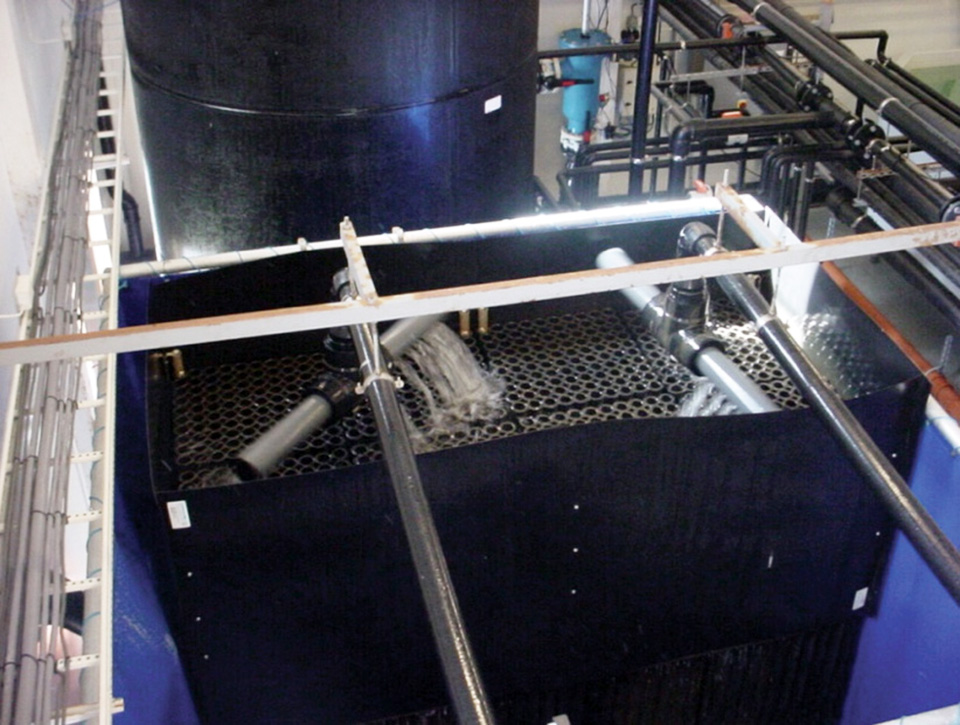

A fully operational seaweed biofilter system was built on site at an intensive fish farm in southern Portugal. At this location, flow-through fish ponds were supplied with seawater from a tidal reservoir, and sea bream were fed with 44 percent-protein commercial pellets. For this study, farm effluent was mechanically screened for particles greater than 150 µm and continuously supplied to 12 aerated seaweed biofilter tanks of 110-l volume.

Several carefully monitored flow rates that resulted in varying water residence times and directly dependent total ammonia nitrogen (TAN) fluxes were tested. TAN concentrations were frequently analyzed in the water that flowed into the biofilters and in each biofilter’s outflow. Multiplications of these concentrations with measured water flow rates then revealed available fluxes of TAN and both absorption and removal efficiencies.

Each tank was stocked with a previously established optimal density of Falkenbergia. Weekly harvests were drained to constant fresh weight in a standard domestic centrifuge and oven-dried for more than 48 hours at 60 degrees C.

TAN flux and yield

Tested biofilter fluxes ranged 0.03 to 7.84 mg TAN per liter per hour. The highest TAN absorption occurred at the highest flux, with a maximum of 1.44 mg TAN per liter per hour, while removal efficiency was higher at lower fluxes. Like absorption, seaweed yield was also found to increase with TAN flux and reached a maximum of 893 grams dry weight per square meters per week. Lower growth was observed during annual extremes of light and/or temperature. Over 10 months, the average biomass yield at non-limiting TAN flux was 446 grams per square meter per week.

Practical compromise

At a water temperature of 21 degrees-C, one metric tons (MT) of commercially fed gilthead bream excretes approximately 500 grams TAN per day. Since TAN is toxic, the water exchange in a flow-through system has to maintain safe conditions. On a simplified level, this translates to a minimum daily water use of 250 cubic meters per ton of fish and an effluent with TAN levels around 2 milligram per liter.

If this water subsequently passes through a seaweed biofilter, a compromise between higher removal efficiency and higher uptake and biomass yield is required. The authors’ model for upscaling this method clarifies this point by utilizing the same amount of wastewater on a varying available biofilter surface area.

It would probably be reasonable and also a workable compromise to remove 50 percent of TAN from the effluent. According to calculations, this would demand a seaweed biofilter surface area of 28 square meters per MT of fish, which would then produce a daily 6.1 kg fresh weight of Falkenbergia.

Feasibility

Although flow-through aquaculture relies on a clean environment, it has by and large refrained from the use of seaweed biofilters. A judicially enforced introduction of integrated mariculture according to the “polluter pays” principle in one area would lead to a market-driven increase of intensive monoculture elsewhere for economic reasons – a globally unviable solution.

Consequently, an ecologically friendly, multitrophic-level mariculture system needs to be economically profitable without extensive governmental support. To be a feasible biofilter, a seaweed species thus has to be directly marketable at a sustainable price. It must also be resistant to low water quality and grow fast, since – as shown in the experiment – the level of nutrient absorption correlates directly with the production of new biomass.

Falkenbergia is a newly discovered fast-growing biofiltration species. Although cultivated in nutrient-rich farm effluent, the occurrence of epibiota and other seaweeds (a common nuisance in seaweed mariculture) is reduced to visually undetectable levels. This could be the result of very low light availability inside the high-density seaweed tanks, but also the species’ secondary metabolites that are active as natural antifouling compounds. These very compounds also make the species a valuable crop that can be marketed.

Conclusion

Research results confirmed the discovery of an easily tank-cultivated, fast-growing and valuable red seaweed that is an excellent biofilter. When Falkenbergia rufolanosa is commercially marketed, it can produce a considerable income for fish farmers and improve the ecological sustainability and public image of intensive aquaculture.

(Editor’s Note: This article was originally published in the February 2004 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Andreas Schuenhoff

Marine Plant Ecology Research Group

Center of Marine Sciences

Gambelas, 8005-139 Faro

Portugal

http://www.ualg.pt/ccmar/algae/[116,112,46,103,108,97,117,64,102,102,111,104,110,101,117,104,99,115]

-

Leonardo Mata

Marine Plant Ecology Research Group

Center of Marine Sciences

Gambelas, 8005-139 Faro

Portugal

http://www.ualg.pt/ccmar/algae/ -

Rui Santos

Marine Plant Ecology Research Group

Center of Marine Sciences

Gambelas, 8005-139 Faro

Portugal

http://www.ualg.pt/ccmar/algae/

Tagged With

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Aquafeeds

Algae alternative: Chlorella studied as protein source in tilapia feeds

Chlorella and other species have potential as protein sources in aquafeeds. In trials with tilapia fry raised in a recirculating system, the fish received a fishmeal-based control diet or feeds with portions of the fishmeal replaced by Chlorella.

Intelligence

An engineer’s design for a classroom aquaculture-aquaponics system

An aquaponics teaching system was designed, built and operated by students at the University of Arizona, integrating its operation and management into the educational curriculum. This engineering design will require minimum maintenance and will last years.