Shinkei Systems aims to ‘democratize access’ to high-quality fish with robotic Ike Jime machine

Michael Fabbro, who was named CEO of New York land-based aquaculture company Local Coho just last year, stresses every last detail of his new company’s recirculating aquaculture system (RAS) to improve quality and reduce waste. Mitigating stress among the animals in the company’s care is one of those details, and it’s an important one because it has a direct link to product quality, he believes.

With more than a dozen years at New Zealand King Salmon under his belt, Fabbro is also leaning on an experience he gained in California when he met esteemed chef Paul Bertolli. From him, he learned the importance of animals’ living conditions and care, right up to the point of harvest. In Bertolli’s case, it was pigs, but some aspects of animal welfare are universal.

“Pigs, when stressed, release lactic acid. It’s a real detriment to quality,” said Fabbro, who said seafood companies are way behind the cattle and pork industries when it comes to humane slaughter techniques. Fabbro’s aim was to establish a humane, ethical harvest protocol for Local Coho fish, and to that end, he found a technology partner in Shinkei Systems, led by young entrepreneur Saif Khawaja.

Shinkei has, according to Khawaja, developed the first automated machine to carry out the traditional Japanese fish-slaughter technique called Ike Jime, which involves instant euthanasia to prevent the release of lactic acid among other chemicals that deteriorate flesh quality. Khawaja likens Ike Jime to Kosher and Halal butchering.

“Our technology will democratize access to otherwise inaccessible quality for fish, fish that you’d have to pay hundreds of dollars in major cities,” Khawaja told the Advocate. “Wagyu beef was not really a thing 15 years ago, now you can find it in the supermarket. There’s definitely an evolving flywheel and exposure for high-quality food. With our technology, people can experience that quality at scale. We’ve built and tested many initial prototypes after long nights in the shop, and we’re excited to partner with LocalCoho for our industrial version.”

[Editor’s note: Click here to listen to the Aquademia podcast episode featuring Saif Khawaja of Shinkei Systems.]

Instead of using a long spike, as in traditional Ike Jime methods, Shinkei’s process employs high-pressure water jets at the back of the head. An additional water jet creates a tail cut to start exsanguination or bleeding. The robotic process achieves the same high quality as the manual Ike Jime technique, Khawaja said. The robot is guided by sensors, edge computing and machine learning to turn data into actionable information.

These processes, Khawaja noted, are basically standard practices in cattle and poultry farming, and unsurprisingly those products, he added, enjoy a long shelf life and are traded in robust supply chains. The technology has been tested on fishing vessels, and the results with fish like fluke and black sea bass have been shown to dramatically extend the shelf life, from a few days to a couple of weeks, in some instances. Waste spoilage is “built into the economics” of seafood processing, he said, something that he’s out to change.

Local Coho (Finger Lakes Fish, Inc.), which hand-harvests its fish, just started using Shinkei Systems’ product in March, harvests about 1 ton of fish per week, with a goal of producing 240 tons per year once the company works through a couple of bottlenecks, said Fabbro. But the company is “hyper-focused” on quality and sees Ike Jime as a differentiator as it makes inroads with foodservice buyers throughout the Northeast U.S. region and online retailers like FreshDirect.

“It’s about more than just cost. The purpose is not to save money. We want to be ahead of the curve, a leader in quality and innovation,” said Fabbro. “We believe that customers, particularly in the culinary world, will be able to appreciate the improved quality from Ike Jime harvest, and that should translate over time to a nice premium price – it’s a premium product. The driving ethos is about quality.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Seafood Alliance

Portsmouth, NH, USA[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,116,104,103,105,114,119,46,115,101,109,97,106]

Tagged With

Related Posts

Health & Welfare

Fish producers benefit from humane slaughter techniques

EU legislation requires farmed fish be spared unnecessary pain, distress or suffering at slaughter, and efficient manual and automated systems have been developed to help achieve this goal. What’s more, longer shelf life and improved flesh quality have been reported.

Health & Welfare

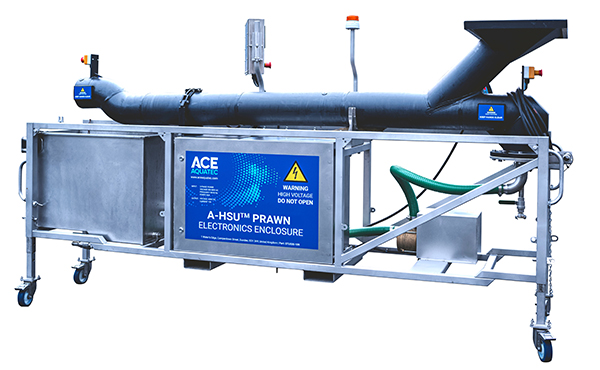

Ace Aquatec launches in-water portable prawn stunner to improve aquaculture welfare

The company's Prawn Humane Stunner Universal can stun prawns unconscious in less than one second, improving animal welfare in aquaculture.

Health & Welfare

‘The right thing to do’: How aquaculture is innovating to reduce fish stress and improve animal welfare

With research showing that stress can damage meat quality, fish and shrimp farmers are weighing the latest animal welfare solutions.

Innovation & Investment

‘AI ticks all the boxes’ and is proving to be a perfect match for aquaculture

Artificial intelligence (AI) is rippling through the aquaculture industry, promising greater efficiencies and insights, as well as investor interest.