The authors review recent studies on shelf-life extension approaches to support the selection of the most appropriate technology and procedures

Seafood is essential to a healthy and varied diet due to its highly nutritious characteristics. However, seafood products are highly perishable, which results in financial losses and quality concerns for consumers and the industry. New trends focusing on reducing synthetic preservatives require innovation and the application of additional or alternative strategies to extend the shelf life of this type of product. Currently, refrigeration and freezing storage are the most common methods for fish preservation. However, refrigeration alone cannot provide long shelf-life periods for fish and freezing can worsen sensorial characteristics and consumer interest. Therefore, the need to preserve seafood for long periods without exposing it to freezing temperatures exists.

A product is considered spoiled once its sensory alterations are so representative that it is no longer fit for human consumption. In seafood, changes in organoleptic characteristics such as fishy, ammonia-like, or sweet odors; off-putting taste; and an overall unpleasant aspect develop rapidly during the spoilage process. This spoilage can be induced by a variety of causes, and the nutritional value of the product also decreases during spoilage.

This spoilage is impacted by the specific properties of the product, conditions of handling and conditions of storage. High concentrations of fat, protein and moisture, in addition to low tissue stability, provide bacteria with an optimum medium for proliferation. Along with degradation and loss of nutritional value of the product, consumer safety can also be affected by the proliferation of pathogenic organisms capable of either producing harmful metabolites or leading to bacterial diseases in humans.

This article – adapted and summarized from the original publication (Rezende, L.P. et al. 2022. Analysis of Alternative Shelf Life-Extending Protocols and Their Effect on the Preservation of Seafood Products. Foods 2022, 11(8), 1100) – discusses the latest advances in the application of alternative techniques of shelf life-extending protocols and their effect on the preservation of seafood products. It is intended to provide information on long-period shelf-life-induction techniques as an alternative to frozen storage.

Biodegradable films, edible coatings and natural preservatives

The application of films or coatings composed of edible and biodegradable compounds allowing the extension of shelf life and freshness periods of seafood products has been the focus of several recent studies. These films and coatings can retard the spoilage of the products by inhibiting bacterial proliferation and promoting a protective layer between the product and the environment, retaining the sensorial properties of fish, such as smell, texture, and flavor. While both techniques are composed of the same compounds, coatings are a specific type of film, which is applied directly on the matrix and is part of the final product, while films possess plastic-like properties and can be separated from the product. Films, being thicker, can be used as biodegradable, chemically active alternatives to plastic packaging.

To achieve formulations with no safety concerns for the consumer, all components must be food-grade and safe to ingest. Should these requirements be followed, films and coatings can be applied to most food products with no threat to consumer health. The use of natural and non-toxic compounds as coating and film materials permits the use of antimicrobials and preservatives while keeping the product free of synthetic additives, complying with consumer demands for safe and natural shelf life-extending technologies. By limiting interaction with the exterior and serving as a semi-permeable layer, films and coatings restrict gaseous transfers, water migration, solute movement, and bacterial respiration. This protection results in the maintenance of sensorial characteristics for extended periods.

Superchilling

Superchilling (SC) or, in more industrial terms, subchilling, is the procedure through which a certain percentage of water in food (around 5 to 30 percent) is cooled below the freezing point. In this process, the temperature of the product is reduced to 1 to 2 degrees-C below its freezing point. At these temperatures, some water solidifies into ice at the surface and slowly starts migrating to the core of the product.

Since traditional techniques for preserving these products consist of storage at refrigeration temperatures (0 to 4 degrees-C) or frozen storage (minus-40 to minus-18 degrees-C), superchilling employs temperatures below what would be regarded as refrigeration, but considerably higher than freezing temperatures. While the interior reaches temperatures lower than the freezing point, the initial superficial ice coating disappears, leaving the product to appear fresh or chilled. The product is then stored for an extended period under these temperatures, preserving its characteristics.

If the right conditions are applied, differences between a superchilled and a fresh, non-treated product in texture, color, and overall appearance are mostly undetectable. This is important to maintain consumer agreeableness and interest. However, the impact of superchilling on quality parameters depends on the intensity of the technique, temperatures applied, and amount of water cooled below the freezing point. Increases in product drip loss, for example, appear to be related to the high percentage of freezing water in the product. Nonetheless, superchilling leads to a considerably longer shelf life than refrigeration.

Effect of superchilling on Atlantic salmon quality through the value chain

Ozonation

Although the use of ozone in the medical field dates back to the 19th century, its use in food production has gained particular relevance in recent years. Mainly being applied as a disinfectant and decontaminant of water, for drinking purposes, the use of this technique directly and indirectly in the processing of solid foods has more recently gathered interest.

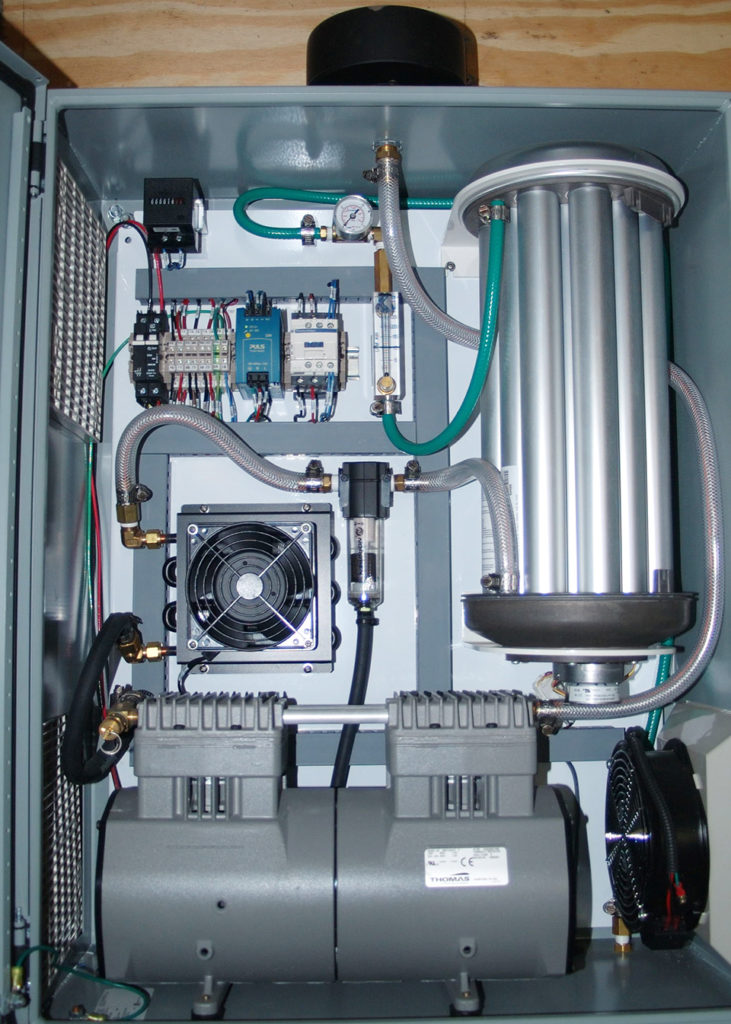

With the introduction of cheaper and more convenient ozone generators, this technique is becoming progressively more accessible to be applied in an industrial context. Ozone interacts with cell components, such as fatty acids, proteins, and amino acids, oxidizing them and consequentially increasing cell permeability. If sufficient doses and treatment time are applied, ozone activity eventually results in the breakdown of cells.

Ozone antimicrobial activity has been shown to be highly efficient in inhibiting the growth of and destroying several microorganisms, including bacteria, yeasts, molds, and viruses. Ozonation affects not only vegetative cells, but also bacterial spores by reducing their ability to germinate. Since the presence of these organisms is a major cause of seafood spoilage, the versatility of ozone in negating the effects of a wide spectrum of spoilage-inducing organisms makes this technique an efficient preservative of sensorial properties and quality characteristics of seafood.

Ozonation can be directly applied, to food products, dissolved in water, through the washing, dipping, or spraying with ozonated water, and in a gaseous state or indirectly applied by including this compound in ice used to keep the product at low temperatures.

Irradiation

The use of ionizing radiation to ensure better microbiological characteristics of food products has been a common practice. Since the irradiation with electromagnetic waves of high frequency on cells results in considerable damage to DNA, the discharge of sufficiently high doses of gamma- and X-rays, as well as electron beams, onto foods reduces bacterial viability and proliferation. This antibacterial activity can induce an efficient reduction in foodborne illnesses and biologically mediated spoilage of foods.

Bacterial inhibition is dependent on the food matrix, bacterial target, and radiation dose applied. Low radiation doses, 0.5 to 3 kGy (kilogray), are tested quantities regarded as safe and efficient in prolonging the shelf life of seafood while maintaining the nutritional values of these products. Higher radiation doses, while displaying increased antibacterial activity, might lead to unwanted changes in hedonic seafood characteristics such as texture, cohesiveness and resilience.

Since this technique also affects fungal cells and spores, this treatment prevents the spread of yeasts and molds. Adding to this, bacterial spores, which are considerably more resistant than vegetative cells and can be found to survive some thermal treatments, are also negatively affected by the impact of electromagnetic radiation.

High-pressure processing and hyperbaric storage

High-pressure processing (HPP) has been regarded as an adequate alternative to the more conventional, thermal, methods of food preservation. It acts by processing the product at high pressures, suppressing bacterial growth and, consequently, extending shelf-life expectancy.

With industrial equipment capable of reaching pressures up to 1,000 MPa [MPa, a megapascal is a x1,000,000 multiple of the pascal unit, the SI (International System of Units) unit for pressure], most enzymes and microorganisms are efficiently eliminated or inactivated. This antimicrobial activity is a consequence of the impact that high pressure has on the denaturation of proteins and the destabilization of cell walls and cell membranes.

HPP has also been found to affect DNA and other physiological activities. Besides being capable of inhibiting the bacterial growth of vegetative cells, HPP is also known to destroy bacterial and fungal spores, yeasts, and molds. Microbial susceptibility to this treatment is, however, dependent on the microorganism’s capacity to resist and repair damages caused by pressure. Bacterial structure, for example, seems to play an essential part in defining the intensity needed to inactivate a specific species, with some bacteria showing increased tolerance to pressure. This is a consequence of the increased cell wall complexity these bacteria possess. Nonetheless, pressures over 600 MPa destroy most vegetative cells.

Bacterial spores are, however, considerably more resistant than vegetative cells; spores of Bacillus cereus and Clostridium botulinum are only efficiently destroyed with pressures over 1,000 MPa. While spores seem resistant to greater pressures than those produced by industrial equipment, researchers have reported that pressures of 500 MPa induced germination of “a large proportion” of Bacillus subtilis spores, leading to the inactivation of at least some of these cells.

Biopreservation

Biopreservation techniques consist of the use of microorganisms and products of microbial origin to preserve and control bacterial proliferation in food products. Produced by lactic acid bacteria (LAB), bacteriocins, peptides with antibacterial effects, have shown efficiency in killing or inhibiting the proliferation of undesirable bacteria in food products. Therefore, LAB and their bacteriocins can be applied to food products with the aim to preserve and consequently extend seafood shelf life.

The use of these natural antimicrobials has been the focus of various studies searching for solutions to the current demands for alternative decontamination methods, and several authors have reported prolonging the shelf life of some seafoods and lowering total viable counts by reducing spoilage bacteria impact on the degradation of the product. Inoculation of food with LAB cultures or bacteriocins can also be used to target specific bacteria such as Helicobacter pylori, which was significantly inhibited by the presence and activity of the probiotic bacterium Limosilactobacillus reuteri, thus reducing the impact of this pathogen and the stomach pathologies provoked by its infection.

In addition to their antimicrobial activity, LAB can also be used as functional agents, improving the antioxidative characteristics of fish and decreasing the presence of free radicals in the product. Their ability to produce various vitamins shows that great value can be added to the product by applying specific microorganisms in food products.

Perspectives

All the techniques discussed appear to be potentially beneficial in ensuring a longer shelf-life for seafood products. Not only can economic concerns be resolved through the investment in new technologies for the processing of this type of food product, but also improvements in food quality, food safety and ecological balance can be achieved. The possibilities to improve the stability and value of seafood, and by consequence, its access to more households, are vast.

Due to the enormous variety of organisms included in the term “seafood,” extensive studies must be performed before choosing the appropriate techniques. Microbiological, physical, chemical, sensorial and economic parameters are just some of the parameters of which consideration is of utmost importance when changes to the processing of a food product are implemented. While shelf-life extension can be achieved by each of the techniques analyzed here, changes to the product might result in negative feedback from consumers.

The application of biodegradable and edible coatings can induce unwanted sensorial attributes, despite showing impact in retarding physical, chemical and microbiological degradation. Changes in color, flavor, smell and texture might be wrongly perceived as indicators of bad quality of seafood, regardless of the increase in nutritional value that the addition of some of these compounds might provide. In the same manner, the physical impact of superchilling might cause organoleptic alterations, especially when the process is not optimized for the specific product.

To our knowledge, no apparent certainties on the public acceptability of superchilled products exist. It is unknown whether consumers’ expectations and willingness to pay for superchilled products are similar to those for fresh products or more akin to those for frozen products. Regarding irradiation and high-pressure techniques, both can alter the sensorial properties of the product if enough radiation or pressure is applied.

The “cooked” appearance of over-pressurized products might reduce consumer interest in such products, even if freshness and shelf-life periods are extended. While hyperbaric storage’s initial cost is significant, the energy-efficient property of this technique, associated with its eco-friendly characteristic, might be beneficial to producers and consumers. The unknown impact of radiation of extremely short wavelengths on food and consequentially on human health raises concerns regarding the safety of such products. Lastly, the application of LAB as biopreservative agents and their antimicrobial activity show considerable influence in extending shelf life.

We believe that, while none of the studied techniques can, by itself, present a solid alternative to replace the freezing of seafood products as the primary long-period preservative method, the introduction of these techniques as additional treatments can improve the preservative action of refrigeration.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Joana C. Barbosa, Ph.D.

Corresponding author

Laboratório Associado, Escola Superior de Biotecnologia, CBQF–Centro de Biotecnologia e Química Fina, Universidade Católica Portuguesa, 4169-005 Porto, Portugal[116,112,46,112,99,117,64,97,115,111,98,114,97,98,106]

Tagged With

Related Posts

Health & Welfare

Ozone treats water, disinfects aquaculture systems

Ozone is a strong oxidizing agent that effectively removes colors, odors and turbidity from water, and kills bacteria, viruses and other microorganisms.

Intelligence

Food irradiation, part 1

In 1997, the United States Food and Drug Administration approved irradiation for meat, which can kill or inactivate 99.9 percent of Salmonella and E coli.

Intelligence

High-pressure processing of oysters

A U.S. study found that high-pressure processing reduced Vibrio vulnificus levels in oysters and can help extend their shelf life.

Intelligence

Effects of red seaweed extracts on shelf life of black tiger shrimp

This study evaluated red seaweed extracts for antioxidant properties and ability to extend the shelf life of black tiger shrimp during storage for 14 days.

![Ad for [BSP]](https://www.globalseafood.org/wp-content/uploads/2025/07/BSP_B2B_2025_1050x125.jpg)