Examining the need for a framework on the biosecure manufacturing of aquafeeds

Any comprehensive biosecurity and veterinary health plan for aquaculture production require the implementation of rigorous and specific measures throughout the value chain. These measures need careful consideration to ensure their standards are achievable and based on scientific evidence and that they safeguard the interests of each stakeholder, and by extension the industry, upon their implementation.

Manufacturing of formulated aquafeeds presents an alternative to the use of fresh and unprocessed feeds, known to pose a high biosecurity risk. However, the standards in place to determine the biosecurity risk of formulated aquafeeds and their ingredients have become highly debated.

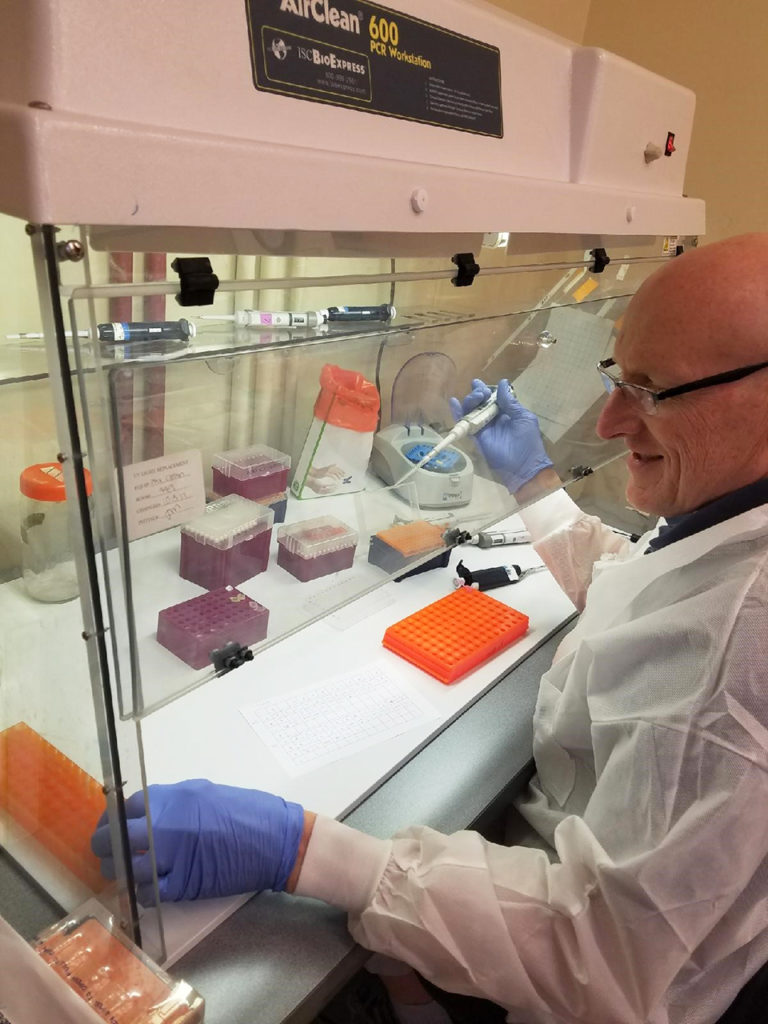

Legislative standards enforced by authorities based on the manual of the World Organization for Animal Health (OIE) are often overly dependent on the results of “…polymerase chain reaction (PCR) methodologies used to detect pathogens in final products.” Current certified PCR methodologies do not allow for a comprehensive assessment of the biosecurity of aquafeeds and are inadequate for the purpose.

Issues with the use of PCR

There are various issues related to the use of PCR as the gold standard for the detection of pathogens (briefly discussed below), when applied to the biosecurity status of formulated aquafeeds.

PCR detection methodologies do not provide information on infectivity

Current PCR detection methodologies only allow conclusions regarding the presence of a specifically targeted, small region of a pathogen genome in inspected samples. The detection of such fragments does not provide any information on the pathogen viability or infectivity, and no consideration is given to the effect of the treatment of raw materials or the manufacturing process in inactivating the pathogen. Indeed, research studies have shown that the serious shrimp diseases caused by White Spot Syndrome Virus (WSSV) and the microsporidian Enterocytozoon hepatopenaei (EHP), for example, are no longer infective after exposure to temperatures below those commonly used in aquafeed manufacturing. However, the feed itself could still test positive by PCR.

In addition, real-time PCR allows detection of pathogen genetic material at extremely low levels. There are no data, however, to support any conclusion of what such results represent in terms of the risk of pathogen transmission and actual clinical disease. Therefore, aquafeeds declared as non-biosecure based on PCR detection may thus be completely safe as illustrated for EHP by Munkongwongsiri, et al. in 2021.

PCR techniques are developed based on non-target matrices

Whether current PCR methodologies are appropriate for the analysis of feed ingredients or finished formulated feeds is debatable. Almost all current PCR techniques for pathogen identification and detection were developed using fresh tissue samples or fresh feeds, which represent a completely different sample matrix. There are examples in which the presence of specific compounds in the matrix may interfere with various steps (e.g., DNA extraction or amplification) during PCR-based pathogen detection. Consequently, false positive or false negative results for pathogen detection may lead to erroneous conclusions, and non-consistency of repeated PCR analysis results can occur.

Current certified PCR methodologies do not allow for a comprehensive assessment of the biosecurity of aquafeeds and are inadequate for the purpose.

Commercially available PCR kits can be unreliable for aquafeeds

The number of OIE-designated laboratories in the world is very limited. There are, however, a wide variety of commercial PCR diagnostic kits that can be used either directly by farmers or, upon their request, by any accessible lab. These kits may vary in their sensitivity and specificity and are used in the absence of OIE-recommended standard operating protocols for sampling and analysis of feeds. Experience has shown that aquafeeds testing positive using such kits frequently test negative upon repeated analysis by an OIE reference lab, or even at the same lab. Nonetheless, as many governments use PCR evaluation to grant certification, farmers follow the guideline of using PCR to assess the biosecurity of aquafeeds, even if the results were generated by non-validated kits.

The simplistic – and incorrect – assumption that “only aquafeeds which are PCR-negative for key pathogens are biosecure” presents major challenges to aquafeed clients, manufacturers and other stakeholders, including:

- Potential loss of client confidence regarding the biosecurity of provided aquafeeds

- Costly product recalls or product refusals resulting in loss of trade and sales

- Excessive registration requirements in importing countries for feed exporters

- Unnecessary reduction in the availability or choice of raw materials for use in feed manufacturing.

- Preventable reputational damage.

All of these challenges represent huge impediments, and increased costs, not just to the aquafeed manufacturers, as they affect also affect their distributors, agents, clients (farmers), suppliers, end consumers and others.

Moving forward

There is a way forward, as aquafeeds certainly can be produced in a fully biosecure way, as recognized by the OIE. Nonetheless, the current OIE guidelines are not sufficiently comprehensive to allow authorities to set standards for feed preparation processes that guarantee biosecure feeds, while being practical and achievable for aquafeed manufacturers.

As a result, the default position is to apply the PCR diagnostic approach despite the many issues mentioned above. We advocate for the creation of a framework on biosecure manufacturing of aquafeeds aimed at developing standards to reassure governments and aquafeed users that aquafeeds are biosecure and represent a negligible risk of disease transmission. Such a biosecurity framework can be developed around several concepts.

The following concepts are proposed to trigger further debate by dedicated expert groups in collaboration with OIE and a representative panel of industry and government authorities:

The appropriate role for PCR diagnostic methodologies

Bioassays (i.e., disease challenge trials) would be the gold standard to determine pathogen viability whenever a positive PCR result is obtained for a specific pathogen. Unfortunately, considering the time and expense involved, such trials cannot be applied routinely for manufacturing batches, as this would pose an impediment to commercial production and raise the cost of feeds for farmers. Consequently, PCR diagnostic methodologies are often used to assess the biosecurity risks of aquafeed ingredients or finished products, although they do not allow for a conclusion on (risk for) viability and/or infectivity of the detected pathogen. Currently there are no ways to determine the viability of the detected pathogen by PCR. Collaborative initiatives between science and industry, therefore, are needed to develop improved PCR (or alternative) methodologies which ensure pathogen detection includes confirmation that the pathogen is non-viable.

Improve biosecurity guidance documents with recommendations and standards for both ingredient/aquafeed manufacturers and governments

In OIE’s Aquatic Animal Health Code, chapter 4.9 “Control of Pathogenic Agents in Aquatic Animal Feed,” several recommendations are given as guidelines for OIE Member states to deal with health hazards associated with aquafeeds. These guidelines, however, lack the necessary validated data to allow governments to establish achievable, necessary, and clear standards. Nonetheless, the Code stipulates that the responsibility to set and enforce regulatory requirements for aquafeeds lies with the individual Competent Authorities.

Given that many competent authorities take their lead from the OIE, more detailed guidelines are needed to ensure that regulatory standards are relevant and equivalent. This would allow governments to develop national and international certification schemes to certify aquafeeds and aquafeed manufacturing facilities with respect to biosecurity. These guidelines can be based on the additional information to be generated as given above.

Aquafeed manufacturers could use these same standards to set up a biosecurity plan that would ensure their production processes deliver biosecure end products. Authorities may be supported in their efforts of certification by independent third-party certification organizations following the same standards.

Perspectives

The views proposed in this thematic paper have wide support from several co-authors and stakeholders (Table 1) that endorsed the content of this paper by signature. All are representatives of either key companies in the aquafeed manufacturing business or leading academic experts in the field. It is their ambition that this text leads to a debate on the need for and the creation of a framework on biosecure manufacturing of aquafeeds in the years to come.

Shinn, Aquafeed biosecurity, Table 1

| Name | Organization |

|---|---|

| Alexander Döring | European Feed Manufacturers Federation (FEFAC) |

| Carlos Zarza | Skretting - Norway |

| Craig Browdy | Zeigler Brothers Inc - USA |

| Hans Nauwynck | Laboratory of Virology, Ghent University - Belgium |

| Javier Ovieda | Federation of European Aquaculture Producers (FEAP) |

| Jie Huang | Network of Aquaculture Centres in Asia-Pacific (NACA) |

| Kallaya Sritunyalucksana | National Science and Technology Development Agency (NSTDA) - Thailand |

| Luis Conceição | SPAROS Lda - Portugal |

| Ole Christensen | BioMar A/S - Denmark |

| Olivier Decamp | Grobest Group - Taiwan |

| Patrick Sorgeloos | Laboratory of Aquaculture and Artemia Reference Center, Ghent University – Belgium |

| Ricardo Mello | SyAqua Siam Co. Ltd. - Thailand |

| Ronald Faber | Alltech-Coppens |

| Sam Valgaeren | Bern Aqua NV - Belgium |

| Sofia Morais | LUCTA SA - Spain |

| Sudhakar Govindam | Alltech - India |

| Zhang Lu | Tongwei Co Ltd - China |

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Eva Werbrouck, Ph.D.

INVE AQUACULTURE, Belgium

-

Peter De Schryver, Ph.D.

INVE AQUACULTURE, Belgium

-

Andy Shinn, Ph.D.

Corresponding author

INVE AQUACULTURE, Belgium[109,111,99,46,101,114,117,116,108,117,99,97,117,113,97,101,118,110,105,64,110,110,105,104,115,46,97]

-

Chris Dinneweth, M.S.

INVE AQUACULTURE, Belgium

-

Matt Briggs, Ph.D.

Ridley AgriProducts Pty. Ltd., Australia

-

Tim Flegel, Ph.D.

National Science and Technology Development Agency (NSTDA), Thailand

-

Daniel Fegan

SyAqua Siam Co. Ltd., Thailand

-

Jim Brock, DVM

Retired

-

Arun Dhar, Ph.D.

Aquaculture Pathology Laboratory, University of Arizona, USA

Tagged With

Related Posts

Health & Welfare

Bacterial testing improves biosecurity at marine hatchery

Microbial surveys of hatchery operations at Oceanic Institute found a strong correlation between hatchery success and cultivable bacteria levels in the water supplied to the larval-rearing systems.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Health & Welfare

Born in Hawaii, SPF broodstock shrimp industry faces globalization

The next step for shrimp breeding will be developing animals that aren’t just disease-free, but increasingly resistant to multiple pathogens. The industry is globalizing, with suppliers setting up shop overseas. But its birthplace will always be Hawaii.

Health & Welfare

The unmet promise of pondside PCR

A new generation of technology, portable PCR, offers potential for affordable, immediate, pondside diagnosis in easy-to-use handheld kits. But will it live up to the hype?

![Ad for [BSP]](https://www.globalseafood.org/wp-content/uploads/2025/07/BSP_B2B_2025_1050x125.jpg)