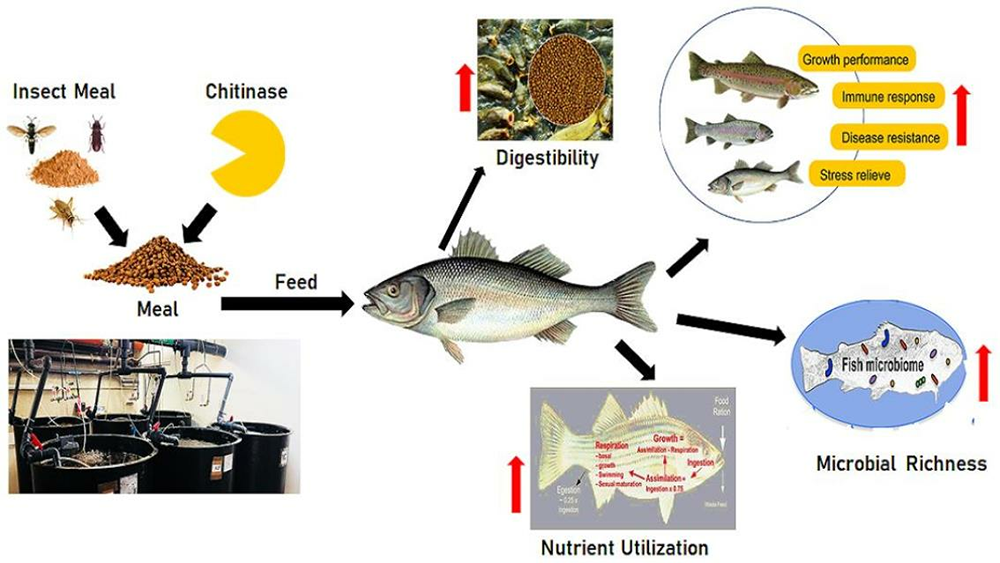

Review highlights chitinase in aquafeeds to improve the use of insect-based protein sources

Chitin – a component of the crustacean and insect exoskeletons – is a nitrogenous, water-insoluble polymer that accumulates in significant quantities in fishery waste due to the processing of crustaceans and mollusks. Chitinase, an enzyme that breaks down chitin, has potential applications in aquaculture, particularly in the conversion of chitin into usable forms and in aiding in the digestion of chitin in fish.

Chitin and its derivatives, such as chitosan, have potential benefits for aquaculture. Chitosan can improve the physiological functions of fish, including growth, immunity, and disease resistance. It can be used as feed additives to promote growth, improve feed conversion, and stimulate the immune system of many farmed animals. However, extensive research is still needed to fully understand the efficacy and potential applications in this area.

This article – summarized from the original publication (Hasan, I. et al. 2023. Chitinase and Insect Meal in Aquaculture Nutrition: A Comprehensive Overview of the Latest Achievements. Fishes 2023, 8(12), 607) – presents an in-depth analysis of the potential applications, benefits, and challenges of using chitinase in aquaculture, focusing on its role in improving feed digestibility, disease control and environmental sustainability.

Enhanced nutrient utilization with chitinase

The enzyme chitinase hydrolyzes chitin into digestible carbohydrates that can be used in fish feed, thus increasing the nutritional value of the feed. One of the ways in which chitinase improves nutrient uptake is by breaking down chitin-containing biomass, such as the waste of marine organisms (like shrimp heads and shells), into simpler, useful components. Once chitin is broken down into simpler oligosaccharides, these molecules become more bioavailable. This means that they can be more easily absorbed in the animal’s digestive tract, contributing to overall nutrient uptake. This process effectively converts chitin waste into a usable form that can be added to fish feed, contributing to improved nutrient utilization.

Preliminary studies have shown that chitin oligosaccharides, products of chitinase activity, could serve as prebiotics. They may promote the growth of beneficial gut bacteria, which in turn play a role in nutrient absorption and overall gut health. Chitinase can be used in the biocontrol of pathogenic fungi and harmful insects as it acts on chitin, a major component of their structures. This function can contribute to disease management in aquaculture as it can help in the control of pathogenic fungi and harmful insects that have chitin structures.

The inclusion of chitinase in aquafeeds can increase chitin digestibility and consequently to an improvement in nutrient digestibility. However, it is important to note that the digestibility of chitin may decrease with higher levels of chitin in the diet. Therefore, while the inclusion of chitinase in the diet may improve digestibility to some extent, the specific increase to be expected may vary depending on chitin intake and fish species.

By adding chitinase, chitin-rich feed ingredients can be utilized more effectively. This can lead to a reduction in feed waste and improved feed conversion, which in turn leads to more sustainable and cost-effective farming. Improved nutrient absorption often correlates with better overall health. Furthermore, the use of chitinase can help to avoid chitin waste, which is a significant environmental problem in aquaculture. Despite these potential benefits, it is difficult to increase microbial chitinase production due to various obstacles, including the inducibility of the enzyme, low titer, high production costs, and susceptibility to challenging environmental conditions. Therefore, further research is needed to optimize the production and application of chitinase in aquaculture.

Role of chitinase in disease prevention and immunity

Chitinases and chitin have been reported to be involved in host immune responses against microbes in a variety of organisms, including fish. In aquaculture, chitinases may play an important role in disease prevention and boosting the immune system, especially when used in conjunction with insect meal.

Insect meal is a rich source of chitin, and chitinases can help to break down the chitin in the feed, thereby improving the nutrient uptake of the fish and enhancing their immune response. Chitinases can improve the immune response of aquatic animals by degrading the chitin coat of pathogens. This can contribute to the prevention and control of infectious diseases in aquatic animals.

Chitinases can increase the resistance of aquatic animals to various pathogens. There are few studies on the long-term effects of chitinase supplementation on aquatic animals. Most studies have focused on the short-term effects of chitinase supplementation on growth, survival, and immune response. For fish to utilize chitin, chitinases must be present in the digestive tract. Previous studies have demonstrated the presence of chitinases in the intestinal tract of fish, suggesting that fish can digest chitin and utilize it as a nutrient source.

Challenges of using chitinase in aquaculture

Chitinases have different sources, properties and mechanisms of action that seem to complicate optimization procedures and make standardization techniques for improved practical applications complex. This diversity can complicate the development and utilization of chitinases in industrial and practical applications. While some fish species can digest chitin, others may not be able to digest it effectively. This may limit the use of chitin as a nutrient source in aquaculture.

There are several challenges associated with the use of chitinase in insect meal. One of the main challenges is the specificity of the chitinase enzymes for certain types of chitin structures, which may be different for different insect species. Selecting a chitinase that effectively degrades chitin in the exoskeletons of the targeted insect species is a significant challenge. These challenges arise from the complex nature of chitin and the variability of chitinase enzymes, as well as specific insect meal processing considerations. The selection of a chitinase that effectively degrades the chitin in the exoskeletons of the targeted insect species remains a major challenge.

Determining the optimal conditions for chitinase treatment in insect meal processing is critical, but these conditions may need to be adjusted depending on the specific insect species and the desired properties of the IM. The effectiveness of chitinase is influenced by environmental factors such as pH, temperature, and reaction time. Studies have shown that the optimal conditions for chitinase treatment can vary depending on the insect species and chitin source. It is important to consider the optimal pH range for the chitinase enzyme used in IM processing.

Chitinase treatment during the processing of insect meals can affect the nutritional composition of the meal, especially the essential nutrients such as proteins and lipids. It is, therefore, important to ensure that the treatment process preserves these nutrients while effectively degrading the chitin. This requires careful optimization of processing conditions, including pH, temperature and reaction time.

The cost of producing chitinase can be high, which may limit its use in aquaculture. Finding a cost-effective method to produce chitinase is important for the industry. Chitinase treatment from lab-scale experiments to large-scale insect meal production involves several challenges related to scalability, cost-efficiency, and maintaining consistent quality across batches. In large-scale chitinase production, the substrate chitin is pre-treated to improve its accessibility to the chitinase, which contributes to a higher efficiency of the process.

Optimizing the processing conditions for chitinase treatment is also crucial for large-scale production. Studies have shown that the optimal conditions for chitinase treatment can vary depending on the insect species and chitin source. Therefore, it is important to carefully optimize processing conditions to ensure consistent quality across batches. In addition to optimizing the processing conditions, it is also important to consider the cost-effectiveness of chitinase treatment. The cost of chitinase production and the availability of chitinase enzymes can influence the overall cost of insect meal production.

Ongoing research and industry developments will continue to shape the understanding of the commercial viability of chitinase in aquaculture. Overall, ongoing research and technological advances aim to overcome the challenges associated with chitinase treatment in insect meal processing and ensure the sustainable and effective use of insect meals in aquafeeds.

Latest technological advances in chitinase production

The production of chitinase for commercial aquaculture operations usually involves microbial fermentation and enzyme purification processes. Microbial fermentation is a key process for the commercial production of chitinase enzymes for aquaculture applications. This process harnesses the productive chitinase-producing capabilities of certain microorganisms, both bacteria and fungi and is instrumental in meeting the aquaculture industry’s growing demands for sustainable disease management and improved feed efficiency.

Bacterial fermentation is one of the most important ways to produce chitinase for commercial aquaculture operations. Chitinase-producing bacteria, such as Bacillus and Pseudomonas strains, are cultured in specialized bioreactors to produce large quantities of chitinase. Bacillus spp. producing chitinases have been used as post-harvest biocontrol agents. Bacillus subtilis isolates with chitinase activity can be cultured in bioreactors to produce chitinase. Pseudomonas spp. are known to produce chitinase and can be cultured in bioreactors to produce chitinase. In parallel, fungal fermentation has proven to be another robust strategy for chitinase production in aquaculture. Chitinase-producing fungi, including species of Trichoderma and Aspergillus, are cultivated under strictly regulated conditions to promote the secretion of chitinase enzymes.

Genetic engineering is a cutting-edge approach that offers enormous potential for improving chitinase production in aquaculture. By modifying microorganisms through genetic manipulation, researchers and biotechnologists can increase chitinase yields, optimize enzyme properties, and contribute to the sustainability and efficiency of aquaculture operations. For example, the genes for chitin metabolism in Atlantic salmon play a role in the development and maintenance of a chitin-based barrier in the fish; genetic engineering can be used to increase the chitinase yield and optimize the enzyme properties in Atlantic salmon.

Several genetic engineering strategies are powerful tools to revolutionize chitinase production in aquaculture. They offer the potential not only to increase chitinase yield but also to tailor the properties of the enzyme to specific aquaculture applications. However, it must be ensured that genetically modified microorganisms comply with safety and regulatory requirements to ensure responsible use of these innovative approaches in aquaculture. Furthermore, as the aquaculture industry continues to expand and diversify, there is a constant need for innovation in fermentation technologies to improve the cost-efficiency and scalability of chitinase production, contributing to the sustainable growth of this important sector.

Perspectives

This review provides researchers, practitioners and stakeholders alike with valuable insights into the evolving landscape of insect-based meals and their applications. It addresses the complexity of chitin and chitosan and explores the role of chitinases and contributes to the pursuit of sustainable and efficient aquaculture practices.

As the aquaculture industry actively seeks environmentally friendly and economically viable solutions, understanding the interplay between insect-based meals, chitin and chitosan is critical. The potential benefits, including improved growth and increased disease resistance, must be weighed against the challenges associated with diet digestibility in certain fish species.

In addition, exploring chitinase as a potential solution to improve the nutritional value of insect meals opens up new avenues for research and application. To realize the full potential of this enzyme, a comprehensive understanding, rigorous research, and strategic optimization of chitinases in aquaculture are required.

Overall, the use of chitin in aquaculture has both potential benefits and drawbacks, and its effectiveness may depend on the fish species and growth stage, but further research is needed to fully understand its application and optimize its use.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Dr. Genciana Terova

Corresponding author

Department of Biotechnology and Life Sciences, University of Insubria, Via Dunant, 3-21100 Varese, Italy[116,105,46,97,105,114,98,117,115,110,105,110,117,64,97,118,111,114,101,116,46,97,110,97,105,99,110,101,103]

Tagged With

Related Posts

Intelligence

Assessing the use of gamma-irradiated chitosan from mangrove horseshoe crabs on refrigerated seafood products

An effective chitosan polymer, developed through gamma-irradiation, could preserve seafood and extend shelf-life beyond capabilities of refrigeration.

Responsibility

Aquaculture byproducts improve sustainability of seafood value chains

Tons of aquaculture byproducts are available as sources for fishmeal and fish oil to supplement the supplies obtained from fisheries. Innovative technologies are supporting more efficient use of these by-products in aquafeed.

Innovation & Investment

Researchers develop a biodegradable film that keeps food fresh for longer

A new biodegradable film is a derivative of limonene from citrus rind, blended with chitosan, a biopolymer from exoskeletons of crustaceans.

Aquafeeds

Chitin digestibility and intestinal enzyme activity in Nile tilapia and rainbow trout

Study results corroborate that chitin could act as a nutrient source as well as an antinutrient in both Nile tilapia and rainbow trout.