Red drum hatcheries planned for Florida

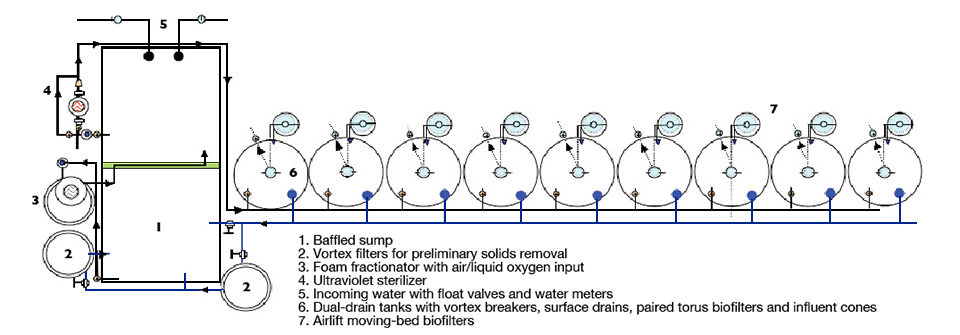

The United States Department of Agriculture Agricultural Research Service and the Center for Aquaculture and Stock Enhancement at Harbor Branch Oceanographic Institute-Florida Atlantic University are collaborating to evaluate low-energy, low-head recirculating aquaculture system designs to intensively produce marine finfish in a low-salinity environment.

This grow-out work is being conducted as part of the Florida Fish and Wildlife Conservation Commission’s saltwater hatchery network initiative to evaluate intensive tank production of juvenile red drum. The design and performance data collected for the system will be utilized to design the recirculating aquaculture systems that the commission plans for new hatcheries throughout the U.S. state of Florida.

The recirculating system design described below has been used in the production of Phase I juvenile red drum (Sciaenops ocellatus) 25- to 45-mm standard length and Phase II fish with standards lengths of 60-100 mm. Future objectives are to evaluate the system for the year-round production of juvenile Florida pompano, cobia and other potential high-value marine finfish species.

System design

The low-energy “hybrid” recirculating aquaculture system consists of nine separate modules that utilize a commercial double-drain fish culture tank paired to a moving-bed biofilter. The nine fiberglass tanks are 1.5 meters in diameter. Normal water depth is about 0.9 meters for a total tank volume of approximately 1.6 cubic meters. The double drain of each tank has a central sump to purge the accumulated solids.

A slotted 5.1-cm-diameter center standpipe transports mid-column water from the tank to the moving-bed torus filter. The standpipe fits into a bulkhead at the bottom of the sump, which is plumbed to the c. Shallow fins on opposing sides of the center standpipe act as a vortex breaker for water and aid the in-tank solids transport to the center drain. Water is airlifted into the biofilter through a 7.6-cm-diameter pipe by flowing air supplied by a 3.5-hp regenerative blower. All piping and fittings are polyvinyl chloride.

Each torus filter is filled with approximately 0.11 cubic meters of commercial floating polyethylene media. A flexible-diaphragm bubble diffuser below the media aerates the media to create toroidal movement within the filter with media rising from the center splashed to the outside and back down to the bottom. Water flows by gravity back into the tank at 15-90 liters per minute, depending on the amount of air supplied into the riser pipe. Typical flow through the filters is approximately 60 liters per minute, which provides two turnovers per hour.

A small, secondary “polishing loop” is included in the system design for fine particulate filtration, oxygen supplementation and untraviolet sterilization. A bulkhead fitting in the tanks provides surface water removal and water height regulation. Surface water from the tanks drains into a manifold which then flows toward the sump. Plastic mesh netting wrapped around the drainpipe prevents fish, feed and media from flowing into the drain manifold.

The water from the drain manifold line gravity flows into a 265-liter wave vortex filter. Matting placed inside the filter improves the capture of large solids. In addition to the in-tank sump purging, this vortex filter is the primary solids filtration device in the water treatment loop. Outflow from the filter enters a second vortex filter filled with commercial media. Outflow from the second vortex filter spills into a 3.2-cubic-meter fiberglass sump.

Water from the front end of the sump is recirculated through a commercial foam fractionator with a high-efficiency pump at about 210 lpm. The 0.56-meter-diameter fractionator stands 2.5 meters tall. Water from the fractionator spills into the back half of the sump, which is separated from the front half by a baffle wall. A 1.0-hp pump returns water to the culture tanks through an 80-watt ultraviolet sterilizer. Return flow ranges 20-35 liters per minute, providing a minimum tank turnover rate of once an hour. Return water is drawn from the back half of the sump, where make-up water is added as needed.

Water returned to the tanks is oxygenated by implementing a small custom Speece cone whose diameter increases as water flows through the inlet and into each tank to allow greater contact time and oxygen absorption. Liquid oxygen is metered in at the top end of the cone in the range of 0.2 to 1.0 standard square feet per minute and flows out near the tank bottom. Preliminary testing indicated absorption efficiency of 90 percent. In case of power outage or pump failure, emergency oxygen is supplied by a simple system of solenoids, flow switches and air stones.

System maintenance

The tank sump is purged two or three times daily to remove any accumulated solids. The matala filter pads are exchanged daily. On a weekly basis, the tanks’ center pipes and drainpipes are scrubbed to remove accumulated solids and biofilm build-up, which hinder the flow out of the tanks into the drain manifold. The drain line is cleaned on an as-needed basis with a rotary spray nozzle and pressure washer unit. Brushing of the tank and sump sidewalls is kept to a minimum when fish are in the system so as not to stress the fish and cause them to cease feeding.

Water quality

Variations of this system have been in operation with varying stocking densities and biomass loads since December 2007. System modifications based on previous culture trials are made in an effort to improve water quality while minimizing capital and operating expenses.

Although initial stocking has varied depending on grading needs, each tank has held over 3,500 red drum with a mean size of 4 grams. Fish biomass in the tanks has ranged from 5 kg per cubic meter at initial stocking to a peak of 55 kg per cubic meter before grading and removal of the larger fish. Feeding rates have been greater than 1 kg feed per day of sinking 50 percent crude-protein pellets.

The water temperature over the course of the year is 25 ± 5 degrees-C. The range is large because the airlift blower is located outside. Salinity for the red drum culture has been maintained at 10 to 13 ppt. Total ammonia nitrogen values range 0.2 to 1.2 mg per liter, and nitrite nitrogen is in the 0.1 to 0.3 mg per liter range.

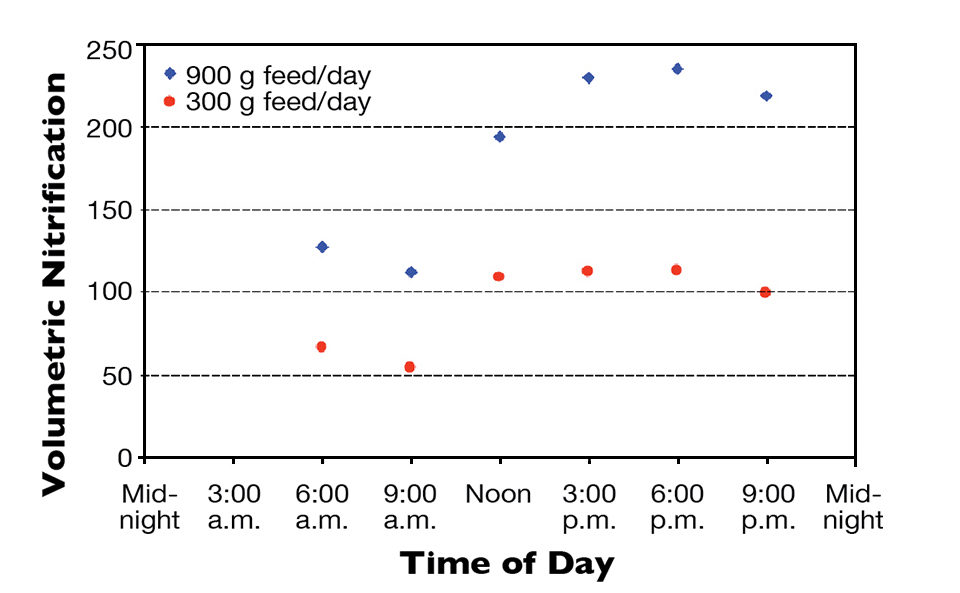

System pH is usually 7.3 to 7.7, as the air input to the torus filters and the return spill into the sump help keep carbon dioxide to a minimum in the system. Alkalinity is maintained around 200 mg/l calcium carbonate by sodium bicarbonate dosing. A graph of the volumetric nitrification rate for the torus filters at two daily feed rates is presented in Fig. 1.

(Editor’s Note: This article was originally published in the May/June 2009 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Timothy Pfeiffer, Ph.D.

USDA Agricultural Research Service

Sustainable Marine Aquaculture Systems

5600 U.S. Highway 1 North

Fort Pierce, Florida 34946 USA[118,111,103,46,97,100,115,117,46,115,114,97,64,114,101,102,102,105,101,102,112,46,121,104,116,111,109,105,116]

-

Paul S. Wills, Ph.D.

Harbor Branch/Florida Atlantic University

Center for Aquaculture and Stock Enhancement

Fort Pierce, Florida, USA

Related Posts

Intelligence

A brief look at genetically modified salmon

If approved by FDA, fast-growing genetically modified salmon will provide a safe and nutritious product similar to other farmed Atlantic salmon.

Intelligence

A land grab for salmon (and shrimp) in upstate New York

The operators of Hudson Valley Fish Farm see their inland locale as a pilot to prove that land-based fish farming, located in close proximity to major metropolitan markets, can be successful.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.