Cumulative effects impact performance, life

While your centrifugal pumps may not have teeth, they can still have cavities due to the ill effects of cavitation. The condition is little understood, but it is safe to assume that a high percentage of centrifugal pumps are operating with some degree of cavitation. Properly sized, installed, and operated pumps will not cavitate, but woe to the sleep of the fish farmer with a cavitating pump – pumps always seem to fail at 2:00 a.m.

What is cavitation?

Nearly everyone who has spent time at a fish or shrimp farm has likely heard a pump that sounds like it is pumping a mixture of water and rocks. This noise is actually the collapse of bubbles against the pump’s impeller that have formed by water “boiling” in the pump suction.

Although the boiling point of water is considered to be 100 degrees-C, it decreases with pressure. Inside a cavitating pump, the pressure is lowered to the point where the water forms bubbles that collapse against the impeller with enough force to literally take a chunk out of the impeller.

The point of lowest pressure tends to remain in roughly the same area of the impeller, which can cause serious damage. First, a little wear affects the efficiency of the pump, demanding more power to move the same amount of water. Then noticeable pitting on the impeller reduces efficiency further. The author has seen holes through impeller fins and entirely missing fins. This throws the impeller out of balance, causing the pump to vibrate and lead to bearing failure (at 2:00 a.m., of course).

How to avoid it

The most obvious answers to cavitation are to begin with proper pump system designs and choose appropriate pumps that can operate at their best efficiency without excess suction pressure. In pumping terms, the net positive suction head available (NPSHa) must be greater than the net positive suction head required (NPSHr) by the pump manufacturer. If you don’t know how to measure NPSHa, every good pump salesman can calculate it based on the expected flow rate, suction pipe length and diameter, and suction lift (vertical distance from surface of water source to pump suction).

Another key ingredient is to physically install the pump in a way that allows the water to flow into the pump suction as smoothly as possible. The rule of thumb here is to have 12 cm of straight pipe for every centimeter of pump suction diameter, so if your pump has a suction diameter of 10 cm, the last 120 cm of suction pipe into the pump should be straight with no elbows.

Whenever possible, place the pump lower than the water level in the reservoir from which you are pumping. This is called “flooded suction,” which in most circumstances will help reduce the occurrence of cavitation – plus you will never lose your prime!

Another practical way to avoid cavitation is to err on the large side when selecting suction pipe diameter and on the short side when determining the suction pipe length. A pipe that is too small and/or too long substantially increases friction losses and suction pressure. In a majority of cases, cavitation can be traced to one of these two issues.

Consider also that bigger is not always better. Three pumps, each capable of half the total flow rate, may be cheaper than two pumps, each large enough to handle the whole flow – and they will likely be capable of handling a higher suction load.

Cavitation treatment

But what if you are stuck with a cavitating pump that needs a new impeller and bearings once a year? Is there any hope of improving things for that pile of metal you depend on to keep your fish alive? If you can’t justify hiring an engineer to design a new system or buying new pumps, there are still a few things you can do to improve your pump’s life and reliability.

- If pumping out of a tank, raise the water level in the tank or raise the tank itself – every inch counts.

- If the suction pipe has unnecessary twists or extra lengths, remove or shorten them.

- Check the insides of your pipes for obstructions or fouling and keep them clean.

- If you have a strainer on the end of the suction line, check it for clogging and keep it clear.

- Always run pumps with all valves on the suction side fully open.

- If your suction line runs underground, be sure it can not collapse from a vehicle driving over its location.

- Although it may seem obvious, don’t pump water that you don’t need. At the very least, restrict the discharge valve. Preferably use a variable-frequency drive with a pressure or level sensor to reduce the speed of the pump. Slowing a pump down can significantly reduce the occurrence of cavitation.

(Editor’s Note: This article was originally published in the May/June 2007 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Philip Nickerson, B.E., EIT

Technical Manager

Scotian Halibut Ltd.

P.O. Box 119

Clark’s Harbour, Nova Scotia B0W1P0 Canada[109,111,99,46,115,105,108,107,64,110,111,115,114,101,107,99,105,110,112,105,108,105,104,112]

Tagged With

Related Posts

Responsibility

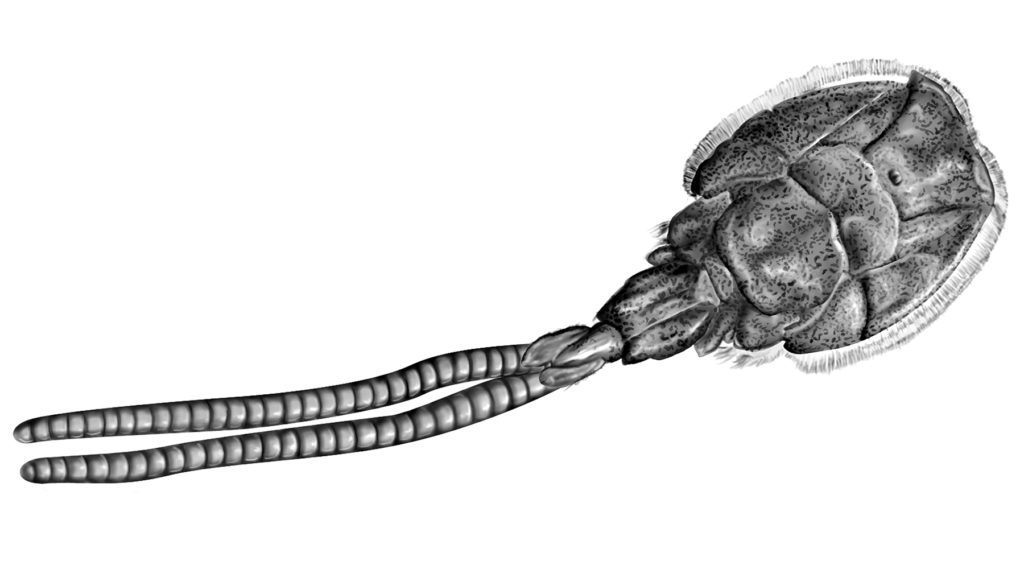

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Responsibility

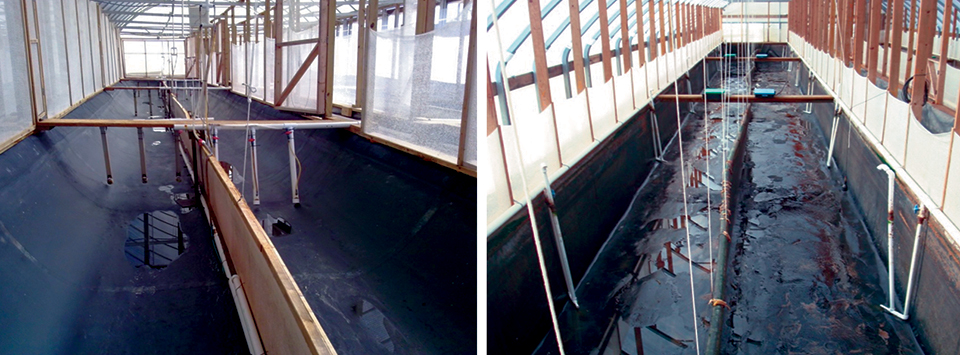

Advances in super-intensive, zero-exchange shrimp raceways

Research at the Texas AgriLife Research Mariculture Laboratory is investigating ways to improve the economic viability of super-intensive raceways for shrimp production.

Aquafeeds

Alternatives to fishmeal perform well in low-salinity shrimp farm trial

In a white shrimp farm trial in a low-salinity environment, alternatives to fishmeal did not negatively impact the growth, survival or FCR of the shrimp.

Health & Welfare

Animal health giants have sea lice in their crosshairs

Alltech and Benchmark have been working on the next generation of sea lice solutions and believe they have new products that can help salmon farmers win.