Efforts focus on optimizing facility location, sizing and growth time

The world’s coral reefs are in decline due to localized and global human and natural factors. Given the large geographic scale (348,000 square kilometers) and mass coral mortality over the Great Barrier Reef (GBR), large-scale reef restoration is being assessed. Coral aquaculture, as one of many restoration methods, is being considered to address mass coral mortality over the GBR. Planning how to best use resources for aquaculture projects to cultivate coral for large-scale reef restoration is vital to efficiently and sustainably deploying grown corals. Mathematical optimization is needed to determine the optimal number, size, and locations of aquaculture facilities to successfully fulfill these large-scale plans.

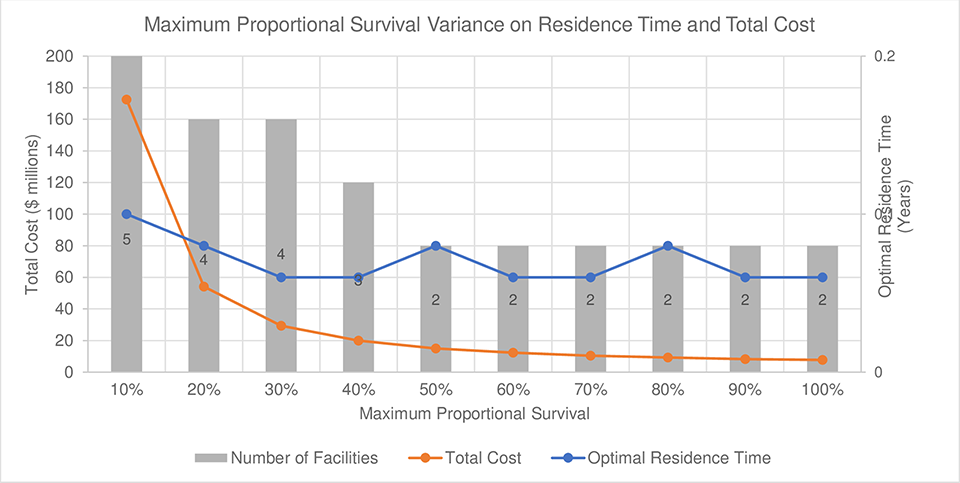

Coral aquaculture operations must be carefully assessed, optimized, and managed to address several issues. In designing such facilities, the growth time allocated for corals after being fragmented and settled in facilities is considered. Optimizing growth time for large-scale coral aquaculture production is crucial to cost-effective production and deployment. The post-deployment survival rate drives production quantity requirements and facility sizing decisions.

Optimal cultivation timing needs to be integrated with facility location and sizing decisions to determine whether it affects optimal strategies to meet production demands. Existing models and approaches in the literature are not suited to solve this problem of locating and sizing facilities for coral aquaculture.

This article – summarized from the original publication (Lippmann, R.B. et al. 2023. Optimizing facility location, sizing, and growth time for a cultivated resource: A case study in coral aquaculture. PLoS ONE 18(3): e0282668) – reports on a study that addresses the several issues faced by coral aquaculture operations, by developing a new fully described integrated mathematical programming decision model that considers facility location and sizing, and a required production volume as a function of growth time. These three aspects have not been integrated into existing models. We considered coral survival rates to generate a minimum-cost solution for the coral aquaculture production process by optimizing the facility location, sizing and growth time simultaneously.

Study setup

Our proposed model considers the construction and operation of land-based ex-situ coral aquaculture facilities over a prescribed planning horizon to cultivate and deploy corals to specified reefs in the wild. We then used this model to optimize the size and placement of the facilities to minimize amortized costs and meet demand for reef adaptation and restoration outcomes. A mathematical programming model was formulated to determine the optimal location and sizing of growth facilities, impacted by resource survival rate as a function of its growth time.

Our method informs strategic decisions regarding the number, location, and sizing of facilities, as well as operational decisions of optimal growth time for a cultivated resource in a facility to minimize total costs. We solved this facility location and sizing problem in the context of coral aquaculture for large-scale reef restoration using a two-stage algorithm and a linear mixed-integer solver. Our model assessed growth time in a facility in terms of its impact on survival (post-deployment) considering growth quantity requirements and growth facility production constraints. We then explored the sensitivity of optimal facility number, location, and sizing to changes in the geographic distribution of demand and cost parameters computationally.

For detailed information on the development of the mode, assumptions and supporting data, refer to the original publication.

A wider view: Conservation aquaculture anchors coral reef restoration

Results and discussion

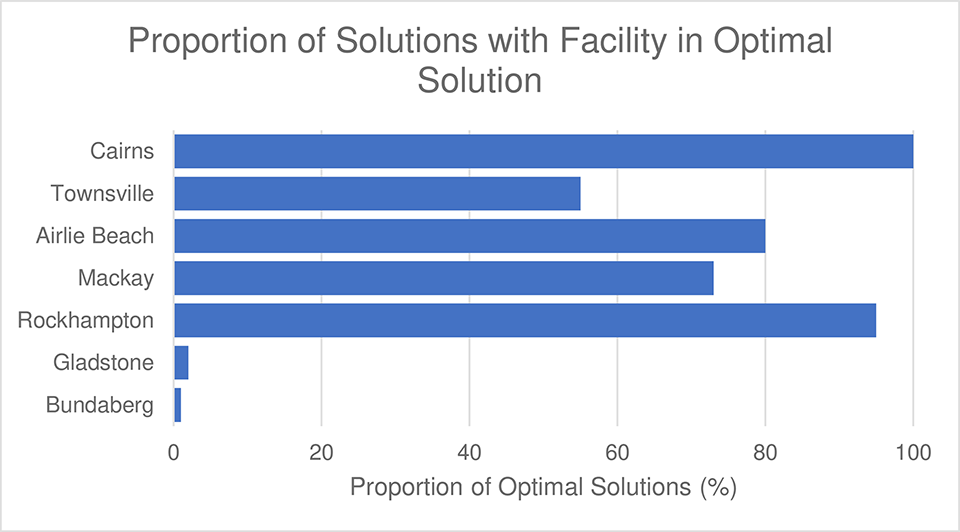

We assessed a large-scale coral aquaculture program aiming to meet the restoration demands of reefs in the GBR Marine Park at a minimal cost. A proprietary dataset containing the name, latitude, longitude and area for 2,816 reefs in the GBR was provided by The Australian Institute of Marine Science (AIMS). The restoration needs and objectives of managers will affect the reefs that require treatment, therefore a randomly selected subset of 50 reefs from the 2,816 candidate reefs was considered to generate demand for coral at specific locations.

Our results demonstrate a method to inform decisions regarding optimal sizing and locating production facilities and grow times for grown resources based on their survival rates. Our model provides a methodological framework to optimize the production of grown resources in facilities to meet spatially dispersed deployment demands. We parameterized and solved this problem in relation to growing coral and deploying them to candidate reefs for a GBR case study. We used potential facility locations at the main ports along the coast of Queensland, an AIMS reef database, and monetized the solution by quantifying homogeneous fixed and variable facility costs, variable operational facility costs and deployment costs.

Our restoration case study is an expensive endeavor and the magnitude of costs are within an expected range considering the given scale. Our method is relevant and transferrable to other datasets with differing demand points, production facility locations and cost parameters. The most directly transferrable application would be cultivated resources with associated survival rates, as the production quantity and consequent facility sizing have been formulated to suit this scenario. The model could be easily adapted to suit the production of other grown resources whose value is dependent on growth time through other proxies, including volume yield or product quality.

The facility location decisions are particularly important as they signify long-term strategic planning, considering the large associated fixed capital costs and significant costs associated with sub-optimal facility establishment. The current assumption of homogeneous costs across facility locations may not be realistic. In practice, more heavily populated locations may be favored as optimal locations, yielding lower costs with greater access to resources.

Optimal growth time dictates deployment frequency. Production quantity is used to inform total floor space requirements driving facility sizing. Cost variation impacts the number of facilities, with the correlation based on the parameter varied. Reduction in the optimal number of facilities is primarily driven by raised fixed capital costs and lowered transport costs. Relatively high fixed capital costs deter additional facility sites, but rather expansion of fewer facilities. Reduced transport costs encourage fewer facilities as the weight of transport costs relative to total cost decreases. Deployment costs (a function of distance traveled between facilities and reefs) have a large impact on the number and location of facilities as these operational costs are incurred periodically; whereas facility establishment costs are incurred once but are relatively large.

The proportion of coral grown that survive in the wild affects the short- and long-term production decisions, impacting total cost. Reduced time in a facility increases production capacity yet impacts coral survival rates. A higher proportion of coral survival allows the production of fewer corals to meet a given demand for surviving corals. Decreased production causes reduced facility, transport and operating costs. Assumptions of the relationship between coral survival and growth time in a facility contain significant uncertainty. Greater certainty of coral survival rates with respect to growth time is recommended to provide more meaningful, accurate, and reliable results.

Consideration of additional factors would improve the accuracy of the model. Extension of the proposed techniques to consider the limited availability and location-specific heterogeneity of transport vessels warrant further investigation in future work. Future facility development and growth considerations optimizing production expansion over time would provide a multi-staged solution to upgrade the existing distribution network based on changing demands. Significant variance is observed in the sizing of facilities with respect to variance in coral survival. Therefore, consideration and assessment for building additional facilities, modular expansion of planned facilities and losses associated with reduced utilization and reduction of existing facilities could be integrated.

This consideration would allow strategic planning decisions to be incorporated into plans for large infrastructure and the implications on long-term cost optimality. Further survival considerations of external environmental factors could be incorporated in this model. Seasonal changes throughout the year affect weather conditions including water temperature, storms and cyclones, water currents and water quality.

Proportional survival may be dependent on deployment locations – defined by their proximity to the equator, coastline, continental shelf, and bathymetric features – and environmental conditions at various deployment times, seasons, depths and locations. Multi-species coral aquaculture production can be modeled, assessed and analyzed for cost optimality with greater certainty of species-specific survival rates.

Perspectives

The proposed model and approach provide a support tool for decision-makers in the production and deployment of grown resources, specifically asexually propagated coral aquaculture. Whilst for the purpose of this study, we have considered land-based aquaculture facilities, our methods could be adapted to investigate increasingly used sea-based in-situ approaches.

Future comparisons between different aquaculture strategies may also consider differing objectives, including carbon footprint, costs and uncertainty of coral survival in less controllable growing conditions. The current model formulation does not consider carbon emissions generated by establishing and maintaining aquaculture facilities: these costs can be incorporated into the objective function in future analysis to consider these factors.

The value of this contribution is an adaptable decision-making tool. A range of considerations can be incorporated in the future via the objective function and model constraints, such as costs associated with carbon emissions and uncertainty of coral survival under variable growing conditions. This model may be extended to environmental restoration projects across marine and terrestrial applications, forestry, aquaculture of fish and other marine species, and livestock agriculture.

With growing demand and scarce resources available for coral restoration projects, optimizing production is vital to their success. In the era of climate change, this is expected to have growing applications in environmental conservation worldwide as active restoration becomes imperative.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Ryu B. Lippmann

Corresponding author and Ph.D. candidate

School of Mathematical Sciences, Queensland University of Technology, Brisbane, Queensland, Australia[117,97,46,117,100,101,46,116,117,113,64,110,110,97,109,112,112,105,108,46,114]

-

Kate J. Helmstedt, Ph.D.

School of Mathematical Sciences, Queensland University of Technology, Brisbane, Queensland, Australia

-

Mark T. Gibbs, Ph.D.

Australian Institute of Marine Science, Brisbane, Queensland, Australia

-

Paul Corry, Ph.D.

School of Mathematical Sciences, Queensland University of Technology, Brisbane, Queensland

Tagged With

Related Posts

Health & Welfare

Concentrations of anti-inflammatory compounds increased in culture studies of coral, microalgae

Authors’ studies indicate that cell culture of symbiotic dinoflagellates may be a viable method of producing a variety of anti-inflammatory agents.

Responsibility

A wider view: Consensus on seafood’s planetary and human health benefits

Several recent reports echo the message that eating sustainable seafood can help save the planet while making significant gains in public health.

Health & Welfare

Artificial diets for juvenile queen conch

Researchers found juvenile queen conch fed diets containing added macroalgae had higher survival than a control given catfish feed only.

Responsibility

Alternatives for reef fishing

Because of the high prices paid for live reef fish, overfishing of species such as groupers and Napoleon wrasse is a common problem throughout their range.