A cost-effective, automated egg-sorting device created by tech leader Bionomous shows promise for aquaculture

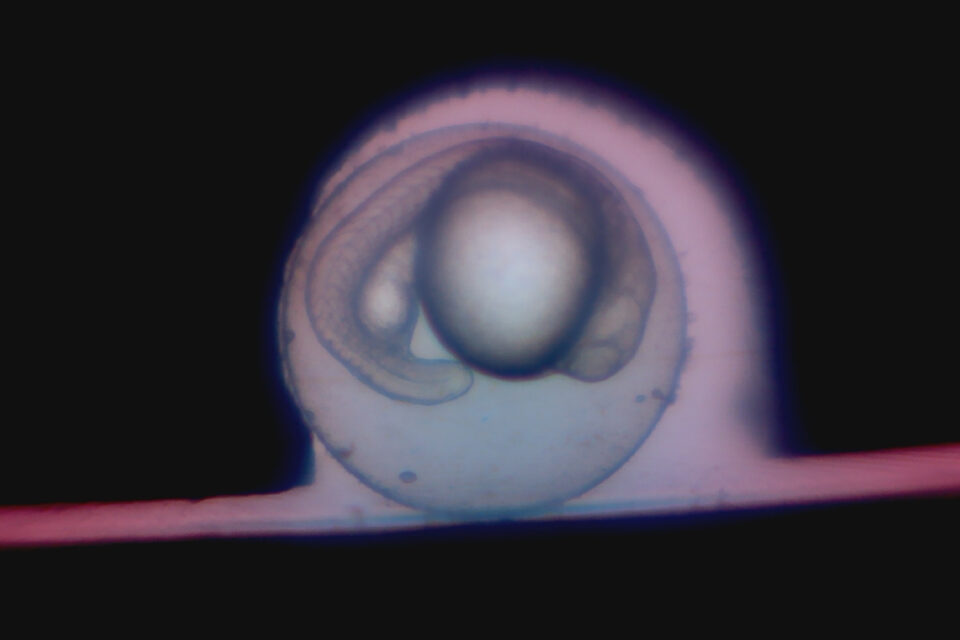

Zebrafish (Danio rerio) are small freshwater fish and popular model organisms in several research fields due to the numerous advantages they represent. However, manual handling of zebrafish embryos is a tedious and time-consuming task due to their small size and the large quantity of samples usually required in an experimental setup. The need for a fast and automated screening method to improve working conditions with zebrafish embryos and larvae has become critical.

Taking on this challenge, Bionomous, a Swiss start-up born at the Swiss Federal Institute of Technology, has found an efficient way to process and sort zebrafish eggs. After a five-year development process, it created the EggSorter – a cost-effective device that automatically carries out the visual inspection, sorting and dispensing of miniature biological entities. And the technology has achieved promising results.

“Bionomous strives to provide means to analyze and sort different fish eggs for which no automated egg quality control is available, while increasing analysis accuracy and speed, improving feed and tank management, ultimately optimizing fish production in a more sustainable way,” says Frank Bonnet, CEO and co-founder of Bionomous.

The Bionomous’ EggSorter is designed to automatically screen, sort and dispense zebrafish eggs or other small biological entities ranging from 0.6 to 1.5 mm in diameter, with a survival rate evaluated at more than 98.5 percent. Individual eggs are sorted according to criteria such as fertilization, reporter gene expression (GFP or mCherry for instance), and stages of development or anomalies which could occur during development, thanks to a large panel of machine-learning algorithms. The classification relies on image inputs which enable image analysis and sorting according to different morphological features with high accuracy and a false discovery rate lower than 4 percent. The device can sort and classify one egg/second and can process 36 samples simultaneously. Overall, up to 3,600 eggs can be analyzed every hour.

Considering the excellent results achieved with zebrafish eggs, the technology has been adapted and expanded to other species. Promising results have already been achieved with killifish and xenopus eggs, and thus, it shows that the device can handle multiple egg types.

The EggSorter has proven to be a valuable tool in research and science and Bionomous intends to adapt and introduce the device into other industries, such as aquaculture. Among the top farmed species in the world, there are several species that would be compatible with the EggSorter, including sea bass, sea bream, eel, cod, carp, Atlantic bluefin tuna, pikeperch, whitefish, turbot, whiteleg shrimp and milkfish.

The EggSorter provides an automated solution to hatcheries for egg quality control and sorting, which are laborious tasks currently carried out manually. Manual quality control is limited by time and human ability, which in some cases is only capable of collecting and testing approximately 100 eggs out of a million-egg batch, which leaves a large margin of error.

Yet, accurate quality control is of extreme importance as the use of tanks, feed and other resources should be planned appropriately and used on the highest quality eggs to maximize hatching and healthy growing and minimize waste of time and money. The current version of the EggSorter can analyze a sample of approximately 3,000 eggs in less than an hour, which, for a population of 1 million eggs, would give a confidence level of 98 percent with a margin of error of 2 percent.

Bionomous is looking to test the EggSorter with the species whose eggs fit the device’s range to adapt the device to fit aquaculture’s needs. The company is now seeking early adopters to test and evaluate the device in their hatcheries to prove the concept and begin the journey of the EggSorter within the aquaculture industry.

If you are interested or have any questions about Bionomous and its technology, or want to test the EggSorter, please email at info@bionomous.ch.

Author

-

Bionomous

This article, from our sponsors at Bionomous, was created by Lorraine Ruffieux, Media Content Creator, and Cristina Anghel Mills, Sales Rep and Business Development, at Bionomous.

[104,99,46,115,117,111,109,111,110,111,105,98,64,115,108,108,105,109,108,101,104,103,110,97,46,97,110,105,116,115,105,114,99]