Slurry ice comprised of millions of ice microcrystals suspended in a liquid brine solution

It has been 25 years since Sunwell Technologies Inc. of Canada first introduced slurry ice technology to the seafood industry. Since then, slurry ice has been widely adopted in major fisheries around the world, where Sunwell and other ice companies work with fishermen and seafood processors to develop and implement better methods of preservation using slurry ice.

Better seafood preservation results in higher yields and fresher products, which translates into higher profits for seafood processors. The two key steps to proper preservation are immediate chilling to near freezing and avoidance of product damage from crushing or bruising.

Bacterial activity

For fresh fish products, a delay of a few hours in chilling to 0 degrees-C can shorten shelf life by days because bacteria multiply rapidly as temperature increases above 0 degrees-C, the temperature of melting ice. According to published data, bacterial growth rate at a temperature of just 2 degrees-C is twice as high as that observed at -1 degrees-C, which is attainable using ice slurry technology. Fish with a shelf life of 15 days at 0 degrees-C will last six days of storage at 5 degrees and only two days at a temperature of 15 degrees before being considered unfit for consumption.

Slurry ice

The advantages of using slurry ice result from the fact that it is comprised of millions of ice microcrystals suspended in a liquid brine solution. These tiny ice crystals, which are typically 0.25 to 0.5 mm in diameter, surround the entire surface of the product being cooled and provide a greater surface area for heat transfer than other forms of ice. This gives it the ability to get large volumes of fish much colder, much faster than conventional flake and tube ice forms, and then keep them colder and fresher for a longer period of time.

Slurry ice crystals have no sharp edges that can harm the surface of fish. In addition, the ice suspends and protects product from bruising, bacterial growth, and tissue degradation, thereby improving yields.

Performance results at many slurry ice system installations in the aquaculture industry have also demonstrated other benefits to farmers and processors, including:

- Increased productivity. Ice slurry can be pumped, which makes it easy to handle, distribute, and deliver to points of use. No manual labor or conveying is required to transport the ice, which results in cost savings associated with equipment maintenance, service, and personnel.

- Better hygiene. Ice slurry is produced and distributed in a totally sealed environment. It does not contact the outside

- environment until discharged at the point of use, which eliminates any risk of ice contamination that can lead to product contamination.

- Overall cost effectiveness. Ice slurry systems are energy efficient and cost effective, with low operating costs, low energy and service requirements, and high cooling efficiency.

Salmon processing

In 2001, Patagonia Salmon Farming S.A. near Puerto Montt in Chile implemented a total quality control process using Sunwell “deepchill” slurry ice. Live salmon is shipped from the harvesting plants to the processing factory and deposited in receiving ponds. They are then pumped directly into a 28-cubic-meter pre-chilling tank in the factory that contains slurry with a low ice fraction, the percentage of ice in the slurry. In this tank, the fish quickly cool from 14 to approximately 2 to 3 degrees-C, but remain alive. Using slurry ice, the fish can be cooled without using carbon dioxide and causing stress on the fish.

The salmon are removed from the tank, cut, and placed in a bleedout tank. This tank also contains slurry ice to continue cooling and preserving the fish. The final stage is the gutting and filleting of the fish. The salmon is kept in totes filled with slurry ice until it is filleted, thereby maintaining the freshest, highest quality salmon possible.

When the company began the process of acquiring a new ice plant in 2000, Managing Director Hans Kossmann wanted an automated system that was less labor-intensive, and provided better temperature control than traditional ice-making equipment. Said Kossmann: “Sunwell helped us develop a complete preservation system in which we use the slurry ice to initially cool the live fish down to 2 degrees-C and afterwards use the same ice in our processing plant to maintain the freshness of the fish throughout the whole process. Integrating the deepchill (slurry ice) system into our entire process at the plant improved our quality significantly.”

Shrimp processing

The successful use of slurry ice is not limited to fish, as several shrimp-farming companies have used ice slurry for years to chill and transport their shrimp. At harvest time, shrimp can be pumped directly into insulated totes half-filled with slurry ice. Having the totes prefilled minimizes the number of workers needed to harvest the pond, thereby reducing labor costs. A couple of quick stirs with a paddle completely immerse the shrimp in the ice.

Shrimp harvested at 24 to 27 degrees-C can be chilled to minus-2 degrees in less than five minutes in the totes when mixed with ice slurry. The crystal ice in the slurry suspends the shrimp and reduces breakage and bruising. The system provides consistent chilling and avoids the hot spots that can result when using other forms of ice.

Cooling tests

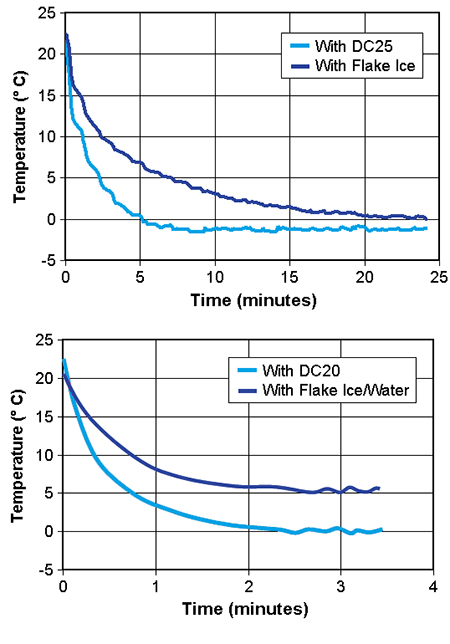

Sunwell conducted tests in Thailand earlier this year at a shrimp-processing plant to measure the cooling ability of its slurry ice using farmed 40- to 50-mm black tiger shrimp. The tests measured slurry with ice fractions of 20 percent (DC20) and 25 percent (DC25), as well as flake ice up to 30 mm in length and about 2 mm in thickness.

Five-kg samples of shrimp were collected upon arriving at the plant, placed in plastic containers, and covered uniformly with DC25 or flake ice. After the peeling process, shrimp from each group were taken from the production line in identical quantities and put in containers filled with either DC20 or a flake ice/water mixture for cooling comparison.

Additionally, samples of peeled shrimp were also taken immediately from the cooker and submerged in DC20 before being fed into the freezer. The temperature of each shrimp sample was measured for each test.

Faster cooling

Test results (Fig. 1) showed the ice slurry provided cooling rates at least three times faster than the flake ice or a flake ice/water mixture for unpeeled and peeled shrimp. Using ice slurry in a chill bath substantially reduced the cooling period between the cooker and the freezer.

Applying ice slurry through spray nozzles increased the cooling rate further, so that a product temperature close to 0 degrees-C could be reached within four minutes. Since the temperature of the shrimp entering the freezer was lower, an estimated 30 percent savings in nitrogen consumption resulted.

The ice slurry lowered the temperature of shrimp from the cooker rapidly on contact and prevented further cooking. The processor said the rapid cooling also preserved moisture in the shrimp bodies and prevented them from curling up.

(Editor’s Note: This article was originally published in the December 2003 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Gabriel Lopez

Sunwell Technologies Inc.

180 Castor Avenue

Woodbridge, Ontario L4L 5Y7 Canada[109,111,99,46,108,108,101,119,110,117,115,64,115,101,105,114,105,117,113,110,105,32]

-

Ming-Jian Wang

Sunwell Technologies Inc.

180 Castor Avenue

Woodbridge, Ontario L4L 5Y7 Canada[109,111,99,46,108,108,101,119,110,117,115,64,115,101,105,114,105,117,113,110,105]

Tagged With

Related Posts

Health & Welfare

Add value to shrimp harvests: Darken environment to enhance shrimp color

Shrimp color is caused by pigments that play an important role in camouflage for survival. For farmed shrimp, proper coloration is generally achieved via synthetic astaxanthin in feed.

Intelligence

As ocean temperatures rise, so too will vibrio outbreaks

A study using a half-century of data has linked climate change and warming sea temperatures with an increase in illnesses from the common vibrio bacteria. Shellfish growers, fighting a particularly virulent strain of Vibrio parahaemolyticus, are changing their harvest protocols.

Responsibility

Calculating chemical treatments for aquaculture production

In calculating chemical treatments to apply to ponds, one must adjust for the percentage of the active ingredients in products. Adjustments for both active ingredient content and specific gravity must be made for liquid products.

Intelligence

Comparing nutritional values of wild and farmed whitefish

A study assessed the nutritional value of farmed vs. wild white-fleshed fishes using hybrid striped bass, largemouth bass and bluegill. Results showed that farmed, white-fleshed fish are as nutritionally valuable – and in some cases, more so – than wild fish.