Hatchery, broodstock development are production priorities at CP Foods

As shrimp price trends have declined, farms must continue to improve both growth rates and survival with predictability and better feed conversion to maintain profitability. Efficient, biosecure hatcheries with access to continuously improved, healthy broodstock are essential for the sustained commercial success of any integrated shrimp-producing company.

Charoen Pokphand (C.P.) Foods Public Co. Ltd.’s Aquaculture Division, for example, made hatchery and broodstock development and production priorities when it made a commitment in 2000 to transition from primarily a feed company to become a fully integrated shrimp producer. Efficiency and reliability were key elements of the company’s development efforts.

Postlarvae, brookstock production

postlarvae 11 months per year.

The foundation of any successful integrated aquaculture company is the reliable production of high-quality, healthy postlarvae. Since C.P. operates throughout Thailand, it developed a network of 10 corporate hatcheries to cover the entire growing area. The hatcheries were designed to deliver scale and reliability, with hatchery capacity ranging 80 million to 900 million postlarvae a month.

C.P.’s modular approach allows constant biosecure operation 11 months/year. Closed recirculation maturation systems with 24-square-meter mating tanks feature controlled photoperiods. Multiple reservoirs with associated water disinfection and treatment equipment provide clean water for operations. Complete algae labs produce Chaetoceros and Thalassiosira microalgae as well as probiotics. Quality-control labs evaluate postlarvae using polymerase chain reaction, stress and microbiological testing. No antibiotics are used.

For Pacific white shrimp, (Litopenaeus vannamei), culture modules can be turned over every 30 days with 40 to 60 percent larval survival to PL8-10. For greatest efficiency, operation levels for hatcheries are coordinated in advance to meet stocking requirements. Since there is some seasonality in Thailand, the hatcheries may operate at 60-100 percent capacity.

High-quality broodstock are needed to produce high-quality postlarvae. In 2002-2003, Charoen Pokphand procured many batches of specific pathogen-free (SPF) shrimp from various locations to serve as the diverse founding population for its broodstock program. Its four biosecure broodstock grow-out farms can now produce over 200,000 SPF broodstock annually.

Genetic improvement

Genetic improvement is an increasingly important facet of the shrimp aquaculture industry. As have other producers, C.P. addresses several areas of improvement in its shrimp, including disease resistance and related survival, growth rates and reproductive performance. The C.P. selection and improvement program utilizes both within- and between-family selections based on families developed through artificial insemination as determined by genetic models.

All families are grown to marketable size in cages in common biosecure raceways at pond grow-out densities and tested for resistance to a local Thai strain of Taura Syndrome Virus (TSV), (Vibrio) and White Spot Syndrome Virus (WSSV) at an off-site laboratory. The largest 5 percent of the animals are selected for further grow-out to broodstock. Other individuals are marked and placed at commercial farms in eastern and southern Thailand for quantification of pond growth and survival. Data collected for each broodstock and family are entered into a database to generate appropriate genetic statistics.

Between the three C.P. facilities that perform selection work, over 1,000 families/year are evaluated, and approximately 200 are selected for the next cycle of mating and selection. A further reduction to 75 families is made for commercial broodstock production.

Positive results

Successful genetics programs can deliver impressive results. For C.P., results from its development program have been positive for both disease resistance and growth rates. Offspring from the original founders had an average 63 percent survival to TSV in standard disease challenges. Every year of breeding increased this resistance level, and in 2006, the average resistance to mortality from TSV in C.P.’s white shrimp was 93 percent. The use of these resistant shrimp has made TSV a minor problem for most shrimp farmers in Thailand.

Charoen Pokphand evaluates the growth rates of shrimp in raceway conditions at a stocking density of 120 animals per square meter. The offspring of its broodstock imported in 2003 had an average weekly growth of 1.3 grams from a 4- to 24-gram size. In 2006, weekly growth improved to 1.7 grams under the same culture conditions.

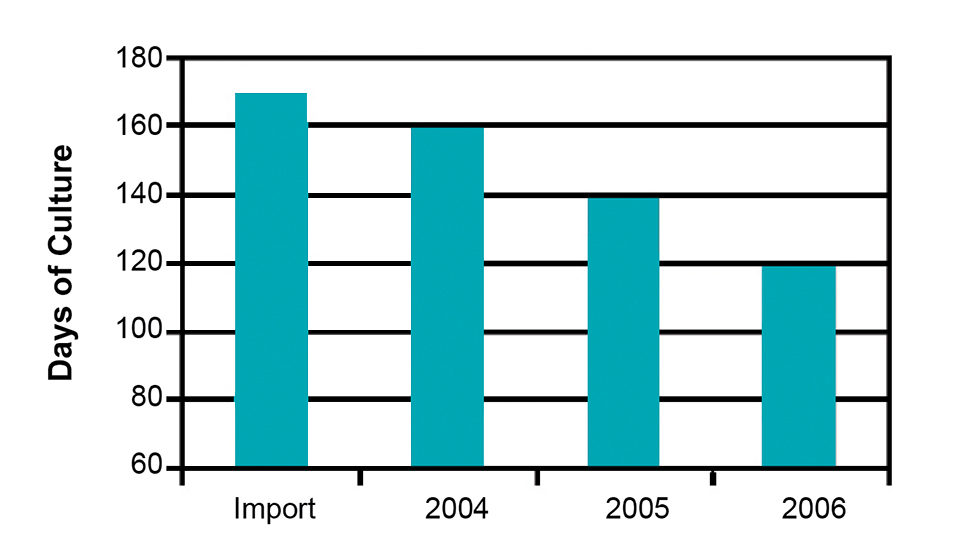

Another measurement of growth is how many days are required to culture shrimp to 24 grams. As shown in Fig. 1, the original imports required an average of 170 days of culture from postlarvae to 24-gram animals in 2003. In 2006, the average family from the C.P. breeding program required only 120 days to reach that size, and some animals from select families took only 90 days.

Such gains from broodstock programs increase farm efficiency, with significant gains in shrimp survival, disease resistance and growth rates. Farm production data at C.P. has also showed that in addition to postlarvae quality and genetics, factors like pond bottom type, pond depth, culture season and stocking density significantly affect shrimp growth. Mean body weights over 25 grams with an average weekly growth of 1.7 grams were achieved in deep, plastic-lined ponds stocked in the months of April-July at densities below 100 per square meter.

(Editor’s Note: This article was originally published in the May/June 2008 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Robins McIntosh

Charoen Pokphand Foods Public Co. Ltd.

C.P. Tower, 27th Floor

313 Siloam Road

Bangkok 10500 Thailand[109,111,99,46,111,111,104,97,121,64,49,48,49,99,109,98,111,114]

Tagged With

Related Posts

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 2

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors considered biotic and abiotic factors. Part 2 describes results of their study.

Intelligence

At Aquaculture Roundtable Series, talk of change for Thai shrimp

The theme of the Aquaculture Roundtable Series in Chiang Mai was “Need For Change.” That means innovations in all production phases of Thai shrimp.

Health & Welfare

Born in Hawaii, SPF broodstock shrimp industry faces globalization

The next step for shrimp breeding will be developing animals that aren’t just disease-free, but increasingly resistant to multiple pathogens. The industry is globalizing, with suppliers setting up shop overseas. But its birthplace will always be Hawaii.

Health & Welfare

The unmet promise of pondside PCR

A new generation of technology, portable PCR, offers potential for affordable, immediate, pondside diagnosis in easy-to-use handheld kits. But will it live up to the hype?