Aerated seaweed grown in tanks a ‘biofilter polishing step’

Soon, all animal production facilities in the United States, including fish hatcheries and farms, will have to meet new discharge standards that comply with the Clean Water Act. These new standards will be enforced by the Environmental Protection Agency (EPA). The EPA’s final ruling on discharge standards is due in June. Although permits will be issued on a case by case basis, it is expected the new standards will require discharge levels generally at or below 25 to 30 ppm nitrogen

Currently, particle filters and biofiltration units that use bacteria are the most common methods used in hatcheries and nurseries to control the water quality of facilities’ discharges. While such systems are good at removing solids and the bulk of the nitrogen, final outflow often still contains relatively high levels of nitrogen above 30 ppm.

Seaweed culture

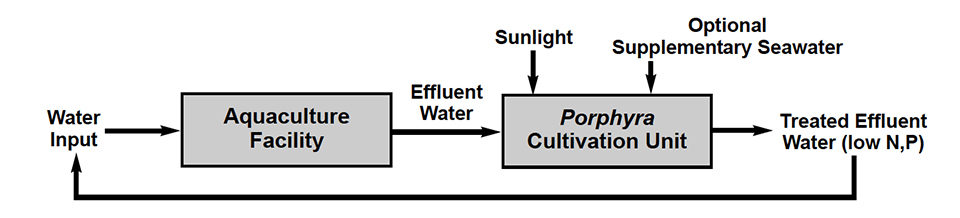

One practical solution is to integrate seaweed culture (Fig. 1) to further remove or “bioremediate” nitrogen and phosphorous nutrients in effluents before they are discharged. The authors are currently developing a freshwater hatchery effluent bioremediation system that uses seaweed of the genus Porphyra to decrease discharge levels and reduce remediation costs through the sale of algal byproducts.

In their system, aerated seaweed grown in tanks serves as the final “biofilter polishing step” in a salmon hatchery. As such, the seaweed reduces the nutrient level of the hatchery’s waste water to a level that would meet the soon-to-be-established EPA discharge standards and possibly be low enough for the water to be recycled. The waste water in turn provides the nutrients the seaweed requires to grow and produce commercially valuable byproducts.

Porphyra

The authors believe Porphyra seaweeds are the best for bioremediation systems integrated with fish farms or hatcheries. These seaweeds are some of the most commercially valuable in the world and the basis of a U.S. $1.5 billion per year industry.

They are cultivated as a source of food called nori and utilized in the preparation of sushi. Porphyra has also been used for years in the biotechnology industry as the principal commercial source of the fluorescent pigment r-phycoerythrin, which is utilized in flow cytometry, antibody labeling, and immunological assays. In addition, Porphyra is rich in a number of other nutritionally beneficial compounds, including the long-chained, polyunsaturated omega-3 fatty acid eicosapentaenoic acid and several carotenoids, including beta-carotene and lutein.

Porphyra’s production potential includes fast growth over a wide range of temperatures and high rates of nitrogen and phosphorus uptake. The easily harvested seaweed can make use of well-developed aquaculture technology and grow at reduced salinity. As a sellable product, Porphyra is rich in valuable pigment and health-related micronutrients.

Poor alternatives

At first it may appear odd to suggest cultivating seaweed like Porphyra to remediate effluents from freshwater fish hatcheries. However, there is no good freshwater alternative in areas like the northeastern United States where salmon is the dominant aquacultured species and the ability of hatcheries and farms to meet EPA’s new discharge standards is a matter of major economic concern.

Freshwater higher plants and algae are not efficient bio-filters in cold water. They exhibit poor growth at the low winter temperatures found in salmon hatcheries, and can be difficult to culture and/or harvest.

For example, the use of water hyacinths and algal mats is limited to more temperate climates, and those approaches lack the ability to produce commercially valuable byproducts. Microscopic algae is more difficult to grow – contamination is one problem – and harvest than Porphyra blades.

Preliminary accomplishments

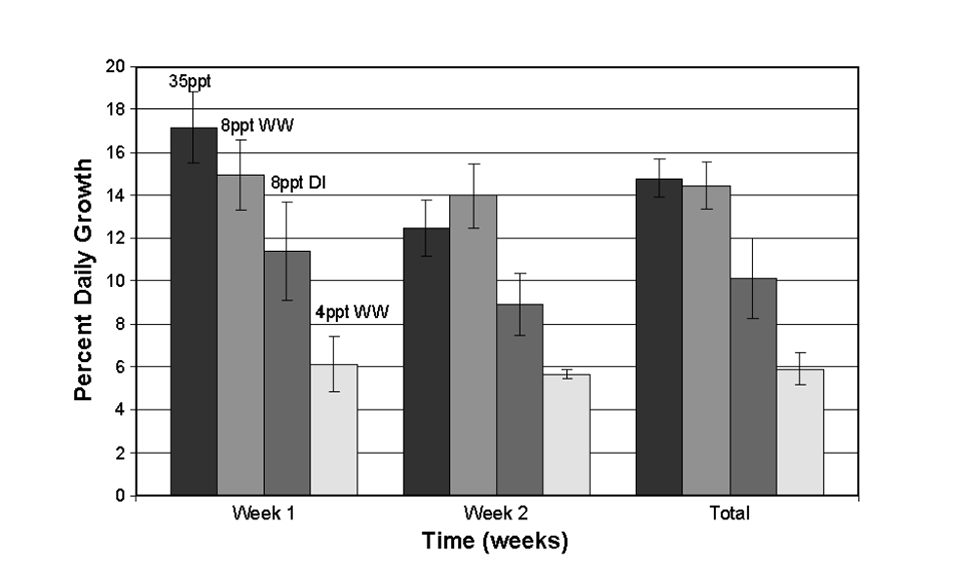

Research efforts have focused on two approaches to develop new cultivars and methods to grow them in freshwater. First, strains tolerant of lower salinities were developed using classic breeding methodologies. Results included the production of monospores and a commercial production rate of 14 percent in 8-ppt salinity.

In a second approach, freshwater was supplemented with certain divalent cations found in seawater. In preliminary experiments, Porphyra plants grew in 4-ppt salinity supplemented with divalent cations at rates comparable to those of normal seawater for at least two weeks (Fig. 2).

(Editor’s Note: This article was originally published in the April 2004 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Ira Levine, Ph.D.

University of Southern Maine

Lewiston Auburn College

51 Westminster Street

Lewiston, Maine 04240 USA[117,100,101,46,101,110,105,97,109,46,109,115,117,64,101,110,105,118,101,108,105]

-

Donald Cheney, Ph.D.

Northeastern University

Boston, Massachusetts, USA -

Brian Curtis

Northeastern University

Boston, Massachusetts, USA -

Leslie Graham

Northeastern University

Boston, Massachusetts, USA

Tagged With

Related Posts

Responsibility

Advancing the ecosystem services of aquaculture

The Nature Conservancy was inactive in aquaculture until new program leader Robert Jones joined. His focus is on the positive outcomes of responsible aquaculture.

Responsibility

Seaweed mariculture provides feed, green energy production, bioremediation

Under cultivation, macroalgae grow rapidly and synthesize large amounts of carbon/energy reserves while utilizing wastewater. Seaweed can remove pollutants from industrial agriculture effluent and reduce coastal eutrophication.

Responsibility

Polyculture: Varied applications, benefits spark renewed interest

Polyculture production boosts fish and/or shellfish biomass and harvests by maximizing the different feeding habits and habitat preferences of varied culture species.

Aquafeeds

Turning to the sea: Can seaweed help us raise more food more efficiently?

Discussion of aquaculture development should consider trophic levels. Seaweed culture, for example, could possibly double plant food production by farming less than 1 percent of the ocean’s surface.