Proactive management through proper feed application, water quality control are critical elements

Postlarvae nutrition, aeration and mixing of the water column are all factors that have major impacts on shrimp performance in intensive zero-exchange biofloc systems. Feeding young postlarvae (P.L.) a properly formulated, high-quality liquid or dry feed can be more convenient and cost-effective than live artemia-based diets. However, feeding the P.L. with the correct feed quality, amount and particle size for their body size is a prerequisite for success. In addition, adequate aeration and water mixing are equally important to continuously and evenly distribute the feed and avoid the formation of anoxic bottom patches during the first period of the nursery phase.

Studies at Texas A & M AgriLife Research Mariculture Labs have demonstrated that pump-driven injectors are suitable for aeration and mixing in intensive biofloc grow-out systems with yields above 9 kg/m3 of marketable shrimp with no need for oxygen supplementation. However, their performance in nursery systems had yet to be adequately evaluated. The authors therefore conducted studies to test the nursery performance of young Litopenaeus vannamei P.L. under growing conditions with different systems for aeration and water handling.

Trial setup

Two, 62-day nursery trials were conducted with five- to 10-day-old L. vannamei P.L. with average weights of 0.93 ± 0.56 mg produced at a commercial hatchery from a hybrid of Taura-resistant and fast-growth, specific pathogen-free breeding populations.

The raceways were filled two days prior to stocking with chlorinated natural seawater at reduced salinity of 30 ppt. No water exchange was conducted throughout the trials. Municipal freshwater was used to compensate for evaporation and water losses to biofloc control. All raceways were manually mixed every second day for the first three weeks. Water mixing and oxygenation were gradually increased over time using the built-in tools in each raceway system.

Solids concentrations were controlled by foam fractionators, settling tanks and cyclone filters installed on each raceway. A commercial nitrifying bacteria and controlled sugar application were used to stimulate nitrification. No sugar was added once the nitrifying bacteria were established.

A commercial probiotic was added every three days to daily. Vibrio concentrations in the culture medium were monitored twice weekly on agar plates. Each raceway had continuous inline dissolved-oxygen (D.O.) monitoring.

Trial 1

Trial 1 was conducted in six lined 40-m3 raceways with 0.45-m depth using P.L. stocked at 675 P.L./m3. Each raceway was aerated and circulated with 18, 50-mm air-lift pumps; six, 0.9-m air diffusers; a 2-hp pump-driven venturi injector; and bottom pipe with spray nozzles. The original experimental design involved feeding P.L. in three raceways a combination of a commercial microencapsulated artemia replacement and dry P.L. feed for the first eight days after stocking, while those in the other raceways were to be fed only the dry feed.

Shrimp size variation at stocking was extremely high – 0.09 ± 0.005 mg – which necessitated abandoning the dry feed-only treatment, as a large number of the small P.L. had empty guts. On days 3, 4 and 5 after stocking, 42 percent of the feed used in the “dry feed-only” treatment was replaced with the artemia replacement to stimulate feed intake.

Identical feeds consisting of appropriately sized particles with nutritional additives were supplied to the shrimp after the first eight days. The feed was added continuously by belt feeders, with rates adjusted on an ongoing basis according to twice-weekly sampling of shrimp growth and shrimp size variation, and assumed growth, feed-conversion ratio (FCR) and survival.

Trial 2

Trial 2 was conducted in two, 100-m3 raceways with 1.1-m average water depth using P.L. stocked at 540/m3. Each raceway was equipped with 14 high-pressure injectors driven by up to two, 2-hp pumps for all aeration, circulation and mixing needs. Shrimp were fed the same dietary regime as those in the artemia replacement and dry feed treatment in trial 1.

Results

Trial 1

Following the adjustments made in the feeding regimes, there was no significant difference in final survival, weight, growth rate yield or FCR between treatments at the conclusion of trial 1 (Table 1). No significant difference (P > 0.05) was found in any water quality indicators between the treatments. Mean temperature, salinity, D.O. and pH were 26.6 degrees C, 30.4 ppt, 6.47 mg/L and 8.20, respectively. Mean total ammonia nitrogen and nitrite levels were 0.79-1.17 mg/L (maximum 4.95 mg/L) and 1.44 to 3.17 mg/L (maximum 10.93 mg/L), respectively, and had no negative impact on the P.L.

Samocha, Performance of shrimp postlarvae, Table 1

| Parameter | Mean Value |

|---|---|

| Survival (%) | 85.1 ± 11.40 |

| Final weight (g) | 5.57 ± 0.55 |

| Growth (g/week) | 0.63 ± 0.06 |

| Yield (kg/m3) | 3.17 ± 0.17 |

| Feed-conversion ratio | 0.75 ± 0.04 |

| Sugar added (kg/raceway) | 30.63 ± 2.70 |

| Bicarbonate added (kg/raceway) | 6.66 ± 1.70 |

Trial 2

At the conclusion of trial 2, shrimp survival was high, and FCR was extremely low (Table 2). The injectors were able to maintain adequate mixing with only one pump, and dissolved-oxygen levels remained above 4.5 mg/L throughout the trial, with no apparent effect on survival or shrimp condition.

| Parameter | Raceway 1 | Raceway 2 |

|---|---|---|

| Survival (%) | 97.8 | 94.6 |

| Final weight (g) | 6.49 | 6.43 |

| Growth (g/week) | 0.73 | 0.73 |

| Yield (kg/m3) | 3.43 | 3.28 |

| Feed-conversion ratio | 0.75 | 0.78 |

| Sugar added (kg/raceway) | 33.36 | 33.09 |

| Bicarbonate added (kg/raceway) | 26.0 | 25.0 |

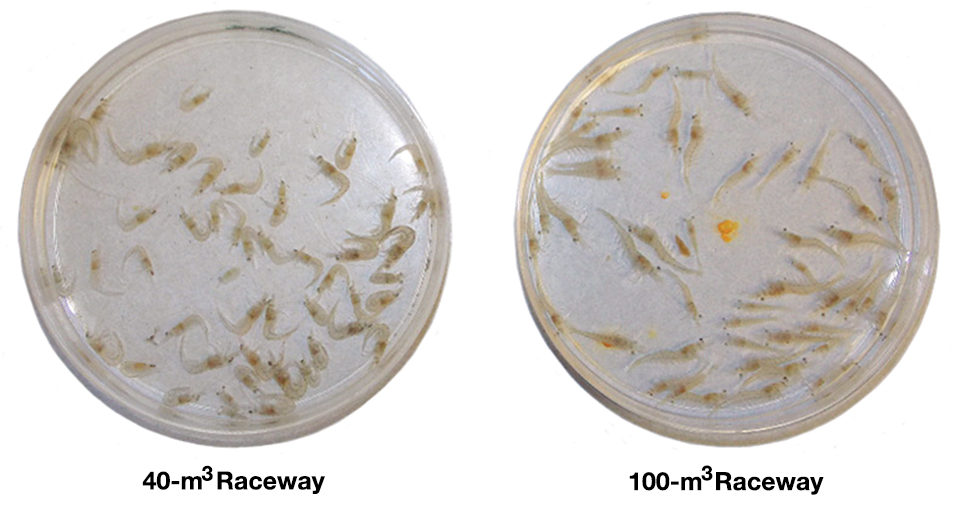

The use of 0.5-, 0.8- and 1.0-mm filter screens on the pump intakes was found adequate to supply the water to run the pump and the injectors without damage to the shrimp. The 6.46-g average weight of the shrimp at harvest in trial 2 was higher than in trial 1, at 5.57 g. The coefficient of variation of the individual weight samples was lower than for the shrimp in the 40-m3 raceways.

Water quality variables were all within the range suitable for L. vannamei culture. Mean temperature, salinity, D.O. and pH values were 26.6 degrees C, 30.4 ppt, 6.67 mg/L and 8.1, respectively. Mean total ammonia nitrogen and nitrite levels were 0.76-0.80 mg/L (maximum 2.72 mg/L) and 1.60-2.27 mg/L (maximum 5.46 mg/L), respectively. The total suspended solids concentration was kept below 511 mg/L for the duration of the trial.

Perspectives

Because of low water temperatures (20.84 to 26.74 degrees C) during the first four weeks, it took 62 days for the P.L. to obtain an average weight above 5.4 g. It is possible the high shrimp size variation also contributed to the extended duration of the trials. The problems with the small P.L. given dry feed only illustrated the importance of observing shrimp and being prepared to respond to unexpected events, such as the arrival of small or variably sized P.L. The use of the artemia replacement was key to providing proper nutrition to the shrimp in the earliest phases, contributing to the final harvest success. Proactive management was critical for controlling FCR and related water quality.

In addition, these results demonstrated that injectors can be used successfully for all oxygenation and mixing needs in nursery tanks stocked with very small P.L. Furthermore, only one 2-hp pump was needed to support a yield above 3.3 kg/m3 of juvenile shrimp with high survival and low FCRs under zero-exchange, biofloc-dominated conditions. Manual water flow control for each injector was key to maintaining adequate dissolved oxygen and preventing damage to the young P.L. from strong mixing action.

Non-sucrose fermenting Vibrio concentrations (green colonies) remained negligible throughout the nursery in both systems, suggesting the benefit of probiotic inoculation.

Future studies will evaluate the use of a programmable variable-speed pump to streamline the control of water flow needed for oxygenation and mixing. The data from the 100-m3 raceways suggested the culture medium was more evenly mixed, with biofloc that developed sooner. Alkalinity declined at a faster rate, and nitrifying bacteria were established sooner than in the 40-m3 raceways.

(Editor’s Note: This article was originally published in the January/February 2015 print edition of the Global Aquaculture Advocate.)

Authors

-

Tzachi M. Samocha, Ph.D.

Texas A & M AgriLife Research

Mariculture Lab at Flour Bluff

4301 Waldron Road

Corpus Christi, Texas 78418 USA[117,100,101,46,117,109,97,116,64,97,104,99,111,109,97,115,45,116]

-

David I. Prangnell, Ph.D.

Texas A & M AgriLife Research

Mariculture Lab at Flour Bluff

4301 Waldron Road

Corpus Christi, Texas 78418 USA -

Leandro F. Castro, M.S.

Texas A & M AgriLife Research

Mariculture Lab at Flour Bluff

4301 Waldron Road

Corpus Christi, Texas 78418 USA -

Thomas R. Zeigler, Ph.D.

Zeigler Bros., Inc.

Gardners, Pennsylvania, USA -

Bob Advent

All-Aqua Aeration

Orlando, Florida, USA

Tagged With

Related Posts

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Aquafeeds

Biofloc consumption by Pacific white shrimp postlarvae

The stable isotopes technique with δ13C and δ15N can be used to determine the relevance of different food sources to shrimp feeding during the pre-nursery phase of Litopenaeus vannamei culture. During this trial, different types of commercial feed, microalgae, Artemia sp. nauplii and bioflocs were used as food sources.

Intelligence

Biofloc technology production promising in temperate zones

A study was conducted to assess the feasibility to grow Channel catfish (Ictalurus punctatus) in an outdoor biofloc system during winter in a temperate zone. High biomasses of market-size channel catfish were successfully maintained through the winter with high survival and in good condition in both treatments.