Network of Maine growers building a robust market for ‘the new kale’

One Tuesday morning in late June, the outgoing CEO and incoming CEO of the first U.S. commercial seaweed farm traveled to business appointments on the Maine coast. During a quick stop for coffee, yet another fisherman approached them to say he was getting into seaweed farming.

Every day there is buzz around the growth of seaweed farming along the Maine coast, said Paul Dobbins, the outgoing CEO of Ocean Approved.

Briana Warner, who took the helm of the company last week, plans to draw on her experience as a food entrepreneur and champion of community economic development to bring Ocean Approved’s seaweed products to retail and make the American diet a little bit greener.

For the past decade, Ocean Approved has simultaneously built its seaweed production operation and pioneered a welcome new industry on the lobster-reliant Maine coast by creating infrastructure like nurseries to grow seaweed starts, promoting the industry as one that’s good for the economy and the environment and promoting the product as tasty and nutritious.

It has shown the ropes of seaweed farming to anyone who is interested – like fishermen looking to diversify their operations as the lobster fishery faces an uncertain future.

“We’re primarily a food company,” said Dobbins. “The supply chain is the sustainable aquaculture of which we’re facilitating the growth of on the coast of Maine.”

Bountiful harvest

All of that legwork and foundation-building appears to have come to fruition and established a new industry in Maine. By Dobbins’ last count, as of a few months ago, 38 of the 54 U.S. commercial seaweed farms are in Maine. He also met with shellfish farmers in Alaska several years ago, who have since started farming kelp. Some farms are small, with about 1,600 feet of rope in the water to support the large fronds of seaweed and others have 30,000 feet – more than five miles – of line.

While the Gulf of Maine waters over the last decade warmed faster than nearly any other body of water on the planet, Maine’s coastal waters are also becoming more acidic. More intense and frequent rainfalls wash excess nutrients, freshwater and pollutants off the land into the sea, raising the acidity in coastal waters.

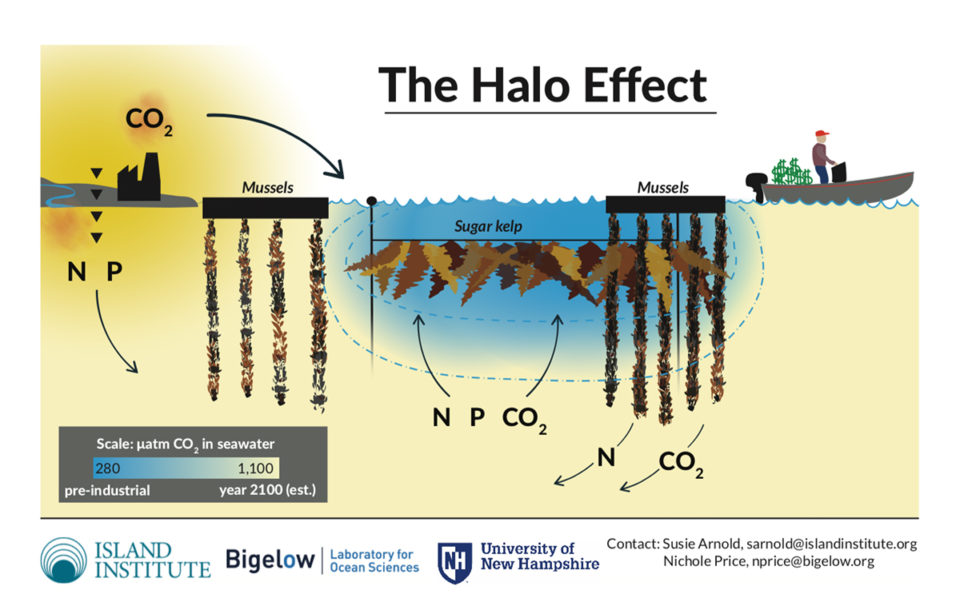

Fast-growing seaweed sucks nitrogen and carbon dioxide from the water. Growing seaweed can apparently make the farm’s surrounding waters less acidic – a theory known as the “halo effect,” the research focus of Dr. Nichole Price, senior research scientist and director of the Center for Venture Research on Seafood Solutions at Bigelow Laboratory for Ocean Sciences in Boothbay Harbor, Maine.

“My research really focuses on that localized solution that remediates water quality in a really small area, and an area where [growers] might be cultivating and harvesting shellfish that are really sensitive to changes in ocean acidity,” said Price.

Her research indicates the potential for calcification of farmed shellfish may be as great as 25 percent higher inside a seaweed farm compared to the outlook for producing shells outside the farm. So researchers and farmers are working on fine-tuning seaweed cultivation in conjunction with mussels, scallops or oysters to mitigate ocean acidification, add income from the seaweed crop and improve overall quality of the surrounding water.

As a rule of thumb, one foot of line can bring $1.60 to $4 at a low sugar kelp harvest, or $4 to $10 at a harvest of 10 pounds per foot. (Based on a low-biomass usable yield of four pounds per foot and high biomass yield of 10 pounds, wet weight, per foot, at a price of 40 cents to $1 per pound.)

Price’s research findings show real-time heat maps of carbon dioxide in the water around seaweed farms show an amoeba-shaped, cloud of lower-CO2 extending beyond the farm that shifts with factors like tides and wind. Sometimes that halo is tight around the farm and sometimes as much as 20 to 30 meters out from it, said Price, noting these are rough estimates from preliminary results.

“Seaweeds are generally happy if there’s more carbon dioxide around,” said Price. “They’re going to be one of those winners in a world in which we continue to emit carbon dioxide.”

Nascent U.S. industry

First things first: This is not the dried, smelly and crusty stuff swarming with flies that washes up on the beach and is left behind at low tide. In Maine, that stuff is rotting rockweed (Ascophyllum nodosum).

Freshly harvested wild rockweed is mineral-rich, used as packing material for lobsters, and in other food, agriculture and supplements applications. It’s been commercially harvested and processed in Maine since the 1970s and makes up 95 percent of seaweed landings.

Edible seaweed – also known as sea vegetables, macroalgae or kelp – has been wild-harvested and dried for specialty, health-food markets over the last several years. It has also been farmed extensively in Asia. China and Indonesia are the world’s largest producers.

The global seaweed aquaculture industry was worth $6.4 billion in 2014, according to the United Nations and reported in an Island Institute study “In Pursuit of Sea Vegetable Market Expansion: Consumer Preferences and Product Innovation.”

Thirteen percent of the global seaweed harvest in 2014 was used to produce hydrocolloids — to form gels in a variety of products — 12 percent was used in agriculture and 75 percent was for human consumption, mostly in Asia, according to the Island Institute report.

What’s new and noteworthy is the nascent U.S. aquaculture industry supplying farm fresh seaweed to chefs, home cooks and inspiring new fresh and frozen food products.

[Seaweed is] going to be one of those winners in a world in which we continue to emit carbon dioxide.

Fresh seaweed, or kelp, has a nice, umami pop and it’s crisp, said Price.

“I think it’s pretty tasty,” said Price. “My family was surprised.”

Its popularity is on the rise as a local, sustainable and nutritious super-food and has become popular with celebrity chefs. It’s even been described as “the new kale.”

In California, for example, Monterey Bay Seaweeds started in 2012 and grows five seaweed species – ogo, dulse, sea lettuce, leaf nori and sea grapes – in recirculating, land-based tanks. It is the only seaweed farm in California, said Dr. Michael Graham, an experimental ecologist at Moss Landing Marine Laboratories at California State University.

Graham started and operates the farm with his chef-restaurateur wife Erica, son Josh and climate-action leader Ross Clark. Their goal: Produce a delicious sea product for chefs using the most responsible and sustainable farming techniques.

“We grow five species that are not easily foraged or grown offshore to limit competition. As such I had to build my market from scratch over last three years. We sell out every week,” said Graham. “California has the best environment in the United States for kelp productivity but much of the coast is not feasible for offshore farming.”

Graham is hosting a meeting “Pathways Towards Responsible Aquaculture in California,” in August to in part help on the policy front to ease state’s permitting process for offshore farms, which he described as “restrictive.”

Ancient organisms

Seaweed is not an animal. Nor is it microalgae, which are the phytoplankton and single-celled algae at the base of the marine food chain. It’s not a plant, either.

Seaweed species are ancient organisms that have existed even longer than land plants, said Price. They are photosynthetic but do not have vascular systems and many cannot concentrate carbon dioxide they need to convert sunlight into energy, said Price.

That’s important to seaweed’s potential to remediate ocean acidification. It means they are extremely sensitive to the amount of carbon dioxide in their immediate environment and pull it directly from the water or convert it from calcium carbonate, said Price.

They are an incredibly diverse group of organisms and there are entire books covering the diversity among seaweed species, said Adam St. Gelais, a research scientist at the University of New England Marine Science Center in Biddeford, Maine, who built one of the handful of nurseries providing seed to the industry.

“Many of those things are tasty for people to eat,” he said.

In Maine, 10 seaweed species are wild-harvested or cultivated. While the name “seaweed” may carry an image problem, the common species names have a much more pleasant ring. Of these, the kelps are the most commonly farmed with some work being done in the reds and greens as well. In particular, said St. Gelais, the most common are sugar kelp (Saccharina lattisma), skinny kelp (Saccharina lattisma forma angustissima) and winged kelp (Alaria esculenta).

It’s an incredibly fast-growing organism and it does this at a time of year when everything else in the ocean is not doing much or growing very little.

Four years ago, the only source of juvenile seaweed for growers was a University of Maine nursery in Franklin, Maine. St. Gelais and UNE, working with the University of Maine on a five-year project to help develop seaweed farming in the state, spearheaded building a new nursery in summer 2015 within UNE’s Arthur P. Girard Marine Science Center. He harvested wild seaweed and kelp and used techniques to raise seed from sugar kelp, winged kelp and dulse, a red species.

In the nursery, seaweed seed is grown on nylon twine wound around a PVC pipe that serves as a spool. At four to five weeks, the young seaweeds are transplanted to a coastal farm. The twine unspools around a main rope – sort of like seed tape in a garden row – and the seaweed then grows into and around the main rope.

“Kelp is nice,” said St. Gelais, “because it remediates both nitrogen and carbon dioxide at the same time.”

The most surprising thing St. Gelais has learned about seaweed is just how prolific it can be.

“I never cease to be blown away by its sheer potential to create biomass,” said St. Gelais. “It’s an incredibly fast-growing organism and it does this at a time of year when everything else in the ocean is not doing much or growing very little.”

In Maine, seaweed farmers put out a 2-millimeter long, juvenile in mid-September, although seaweed can be “sown” as late as mid-December. Within four to five months, that teensy organism becomes a 3- to 4-meter blade. Harvest is mid- to late March and into early June.

This timing happens to complement the down-times of lobster fishing almost perfectly.

Visionaries

“The industry in Maine was really driven from within,” recalled St. Gelais. The visionaries and pioneers were Ocean Approved founder Tollef Olson and Paul Dobbins. “Their success drove a lot of interest.”

Several other Maine entities that work toward economic and environmental sustainability have been proponents, from academic marine scientists to Maine Sea Grant, the Island Institute and the Hurricane Island Foundation. They all seem to have put their collective oars in the water and rowed hard these last few years.

“There’s been a reasonable expansion of people who are really interested in being growers and a lot of entities in the state that have jumped into the fray and are trying to move the industry forward in a meaningful way,” said St. Gelais.

Warner, the incoming CEO of Ocean Approved, most recently held the post of senior community development officer at the Island Institute, which works to sustain Maine’s island and coastal communities. She co-authored the Island Institute’s sea vegetable report with James Griffin. The Island Institute invested in Ocean Approved as a way to build processing of a Maine seaweed crop.

“It became very clear to me that the opportunities for seaweed were abounding and Ocean Approved was providing a diversified income source for coastal fishermen. [It was] working toward sustainable growth of an industry that would provide positive ripple effects throughout the coast,” said Warner.

Steady, predicted growth

That seaweed farming is catching on is no surprise to Dobbins. About a decade ago, he and Olson studied the industry and market opportunities for seaweed farming in the United States and created a strategic plan.

“This is exactly how Ocean Approved thought this would roll out in the market, which is slow, steady growth and very pragmatic expansion of the industry,” said Dobbins. “What we’re experiencing is not a boom but planned, very rational growth of a nascent industry in the United States – but one practiced around the world since before the written record. I think we’re doing it in a very sustainable and pragmatic way.”

Ocean Approved operates two farms in Casco Bay to help facilitate innovation and research into seaweed farming, two nurseries in Southern Maine, and a processing facility in Saco, Maine.

“We are as green as can be,” said Dobbins.

Increasingly familiar

Dobbins and Warner both see big market potential for seaweed at retail. One reason is that Ocean Approved’s three frozen seaweed products – kelp slaw, kelp salad (Seaweed salad) and kelp cubes that can be added to smoothies for a nutritional boost – are doing well in foodservice, which makes up 99.5 percent of its sales. Through distributors, the products are sold to individual restaurants and small restaurant chains, colleges and prep schools and the retail dining side of medical facilities, primarily along the East Coast and in the Pacific Northwest.

Phillips Exeter Academy in New Hampshire uses kelp cubes in its “Flu Fighter” smoothies and serves 500 in a lunch period, noted Dobbins. The organic salad at the Flatbread Company, a 16-location New England pizza chain, includes Maine sea kelp.

Warner in 2013 founded Maine Pie Line, a company that produced sweet/savory pies from recipes she acquired while living around the world as a diplomat with the U.S. Foreign Service, and employed refugees newly settled in Maine. She sold the pie company in 2015.

She was encouraged when she saw her 12-year-old niece enjoying seaweed snacks on a recent visit to central Pennsylvania. In three to five years, Warner expects to see her niece enjoying fresh seaweed – or kelp or sea vegetables – in many other ways.

“If you make it taste good you can call it whatever people want,” said Warner. “If it tastes good, it will speak for itself.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lisa Duchene

Lisa Duchene has reported on the marine environment for two decades. She is a business-environment writer and communications consultant in central Pennsylvania. Lisaduchene.com.

Tagged With

Related Posts

Responsibility

Can sustainable mariculture match agriculture’s output?

Global, sustainable mariculture production, developed on a massive, sustainable scale and using just a small fraction of the world’s oceanic areas, could eventually match the output of land-based agriculture production. Scale and international law considerations require the involvement of many stakeholders, including national governments and international organizations.

Responsibility

Can aquaculture flourish in a more symbiotic sea?

The 18-month Maribe project has uncovered some promising ideas for promoting growth and jobs within the blue economy. Aquaculture, fingered as one of five key areas for growth, could benefit from collaboration with renewable energies.

Responsibility

Can ranching ‘zombie urchins’ boost uni, save kelp forests?

With Norwegian knowledge and a partnership with Mitsubishi, Urchinomics aims to turn worthless empty urchins into valuable seafood while restoring kelp forests and creating jobs.

Responsibility

Lease, seed and repeat: GreenWave’s replicable aquaculture

Don’t call it integrated multi-trophic aquaculture: Former commercial fisherman Bren Smith says polyculture of non-fed species is the future of aquaculture.