In RAS, feed conversion, growth rates not impacted

In recent years, interest in the production of largemouth bass (Micropterus salmoides) has steadily increased in the United States. However, the current production systems utilized by the commercial aquaculture industry in Arkansas, the top U.S. bass-farming state, create an extended culture period of two to three years, which tends to limit the economic feasibility of food fish production of largemouth bass.

Spawning techniques and pond culture practices for largemouth bass have been well established since the 1960s. Farmers typically rely on natural spawning in the early spring, rearing fry in nursery ponds, feed training small fingerlings in indoor tanks and restocking larger feed-trained fingerlings to ponds. While this method can be effective, it has some drawbacks. One key issue involves the reintroduction of feed-trained fingerlings to growout ponds in the middle of the summer, which can result in poor survival due to factors such as water quality, disease and bird predation.

Alternative: Recirculation systems

Researchers in Florida recently reported the successful production of advanced bass fingerlings in the fall and early winter months using controlled spawning techniques. Utilizing these in Arkansas, which has much lower winter temperatures, could be problematic for commercial producers.

To sustainably produce largemouth bass and shorten the overall culture period for the food fish market, commercial producers will need to rely on new culture techniques. The use of a recirculating system would allow control of culture temperature during the winter months, making year-round production of largemouth bass feasible.

Biomass control

Biomass density is a critical husbandry factor in closed or semi-closed recirculating systems. Existing aquaculture production strategies often manipulate biomass density by harvesting, grading and transferring to increase production.

The effects of biomass density can be species-specific and also depend on social interactions at very low and/or very high biomass densities. In predatory fish such as largemouth bass, biomass density may need to be adjusted for cannibalism. While there is some data in the literature on pond production techniques, little research has been conducted on biomass densities of largemouth bass raised in recirculating systems.

RAS study

The authors designed a study to evaluate a culture paradigm for producing advanced largemouth bass during the winter using feed-trained bass fingerlings in a semi-closed recirculating system. This trial examined the effects of biomass density on the size variability and growth performance of the fingerlings.

During the winter of 2013, feed-trained largemouth bass fingerlings of 9.04 g initial weight were secured from Dunn’s Fish Farm in Brinkley, Ark., and transported to the Aquaculture Research Station at the University of Arkansas at Pine Bluff. The semi-recirculating experimental system, which had a total water volume of 3,500 L, consisted of 18 square plastic tanks, a radial flow settler, a sump, a moving-bed filter, a centrifugal pump, a sand filter, a down-flow oxygen saturator and an ultraviolet sterilizer. The daily water exchange rate was 30 to 50 percent.

The fingerlings were stocked at experimental biomass densities of 15, 20, 25, 30, 35 and 40 kg/m3 (treatments T1, T2, T3, T4, T5 and T6) with three replicate tanks per density. Water temperature was maintained using submersible heaters. Gentle aeration was installed in the middle of each tank for mixing water and efficient solids removal toward the center drain.

The fish were fed a formulated diet with 42 percent protein and 16 percent lipid, distributed by automatic feeders from 9 a.m. to 9 p.m. The daily feed ration was initially set at 5 percent of total body weight and readjusted to the initial body weight weekly. Mortality was checked twice daily.

After 60 days, feed-conversion ratios, specific growth rates and survival rates were determined. Ten percent of the total population in each tank was randomly sampled to measure individual body weight and length. Based on individual measurements, coefficients of variation (C.V.) were calculated to evaluate the effects of biomass density on size variability.

| Treatment | 15 kg/m3 | 20 kg/m3 | 25 kg/m3 | 30 kg/m3 | 35 kg/m3 | 40 kg/m3 |

|---|---|---|---|---|---|---|

| Final weight (kg) | 8.6 d | 11.6 c | 13.1 c | 16.9 b | 17.9 b | 20.9 a |

| Gross yield (kg/m3) | 51.2 d | 70.0 c | 78.8 c | 101.5 b | 107.6 b | 125.6 a |

| Feed-conversion ratio | 0.96 | 0.94 | 1.08 | 0.99 | 1.13 | 1.10 |

| Specific growth rate (%/day) | 2.03 | 2.07 | 1.90 | 2.01 | 1.85 | 1.89 |

| Survival (%) | 95.0 b | 96.1 ab | 96.4 ab | 96.2 ab | 97.4 a | 96.8 a |

Results

The water temperature was stable at 25.4 ± 1.6° C, and dissolved-oxygen concentrations remained above saturation for all treatments. pH and alkalinity were 6.93 ± 0.26 and 53.3 ± 8.7 mg calcium carbonate/L, respectively. The average total ammonia nitrogen (TAN) and nitrite-nitrogen concentrations were 1.88 ± 0.62 and 0.67 ± 0.48 mg/L, respectively. The TAN concentrations in the T4, T5 and T6 treatments were significantly higher than those in T1 and T2.

Survival ranged between 95.0 and 97.4 percent across all treatments (Table 1). The survival rates in the two highest biomass densities (35 and 40 kg/m3) were significantly higher than at the 15 kg/m3 density, but were not different from the rates under the 20, 25 and 30 kg/m3 treatments. Biomass density did not appear to affect the feed conversion and specific growth rates of the largemouth bass fingerlings. Biomass density significantly affected production rates, with production ranging 51.2-125.6 kg/m3.

| Treatment | 15 kg/m3 | 20 kg/m3 | 25 kg/m3 | 30 kg/m3 | 35 kg/m3 | 40 kg/m3 |

|---|---|---|---|---|---|---|

| Final individual length (cm) | 13.1 | 13.2 | 12.8 | 13.0 | 12.6 | 12.8 |

| Final individual weight (g) | 28.7 | 29.8 | 27.3 | 28.6 | 26.9 | 28.1 |

| Condition factor | 1.24 | 1.26 | 1.25 | 1.24 | 1.28 | 1.31 |

| C.V. -- total body length (%) | 8.7 | 10.0 | 11.4 | 10.9 | 11.2 | 11.1 |

| C.V. -- body weight (%) | 26.9 | 32.4 | 36.1 | 36.6 | 36.2 | 34.4 |

| C.V. -- condition factor (%) | 8.5 | 8.3 | 8.9 | 8.2 | 8.1 | 9.2 |

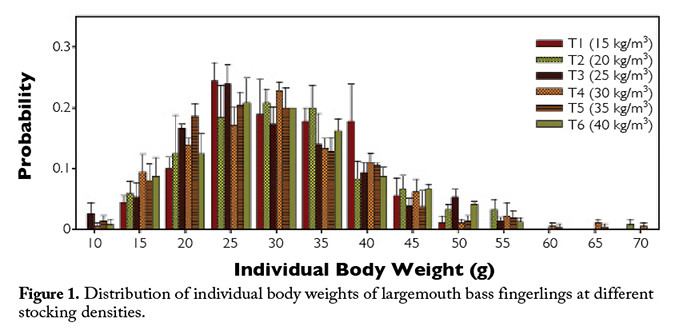

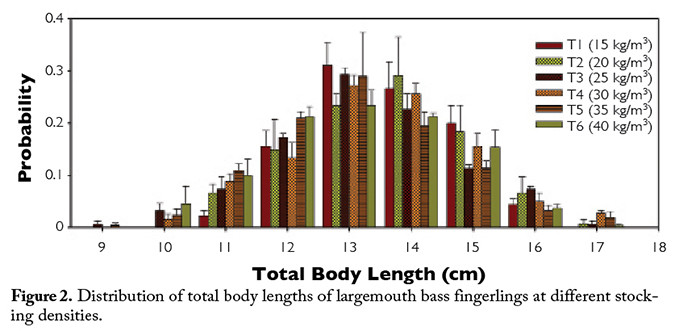

Coefficients of variation in total body length, individual weight and condition factor at the end of the experiment did not show any differences among treatments, but uniformities for those parameters tended to be lower in the highest biomass density (Table 2). Distributions of total body weight and total length by treatment are shown in Figures 1 and 2.

Perspectives

Intensification is vital for maximizing fish production within a given culture system. However, in some cases, high biomass density can result in profit loss due to growth reduction, high mortality, impaired feed conversion or a high level of size variability. To avoid such problems, the level of intensification for largemouth bass should consider the production phase.

In an intensive system, determining optimal biomass density is a compromise process that maximizes yield, minimizes individual growth reduction and maintains an adequate culture environment. In fingerling production, size variability is likely another important factor, since greater size variation can reduce the efficiency of nursery management and ultimately extend the culture period.

A biomass density of 100-125 kg/m3 from the initial biomass density of 30-40 kg/m3 may be attainable for largemouth bass up to 30 g in weight reared in a semi-closed recirculating system.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Jeonghwan Park, Ph.D.

Department of Aquaculture and Fisheries

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff, AR 71601[109,111,99,46,101,118,105,108,64,48,57,107,114,97,112,106]

-

Nilima Renukdas, Ph.D.; Trevor Luna; Luke A. Roy, Ph.D.

Department of Aquaculture and Fisheries

University of Arkansas at Pine Bluff -

David Heikes

Dunn’s Fish Farms, Inc.

Brinkley, Arkansas, USA

Tagged With

Related Posts

Aquafeeds

Increased density improves grouper feeding response, growth

A growth trial using hatchery-reared grouper was carried out to study the effects of stocking density on feed intake and subsequent growth. Contrary to common perceptions, fish stocked at the highest density had higher feed intake and body weights.

Aquafeeds

Maximizing nutrition for adult marine fish

Since fish consume more feed in the final stages of growout, the development of ecologically efficient and nutritionally adequate diets for adult fish should be a priority. Digestible protein-digestible energy ratios are important for optimizing feeding efficiency in feed formulation and aquaculture production.

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Intelligence

Adding flavor complexity to farmed barramundi

Organoleptic attributes such as flavor and aroma are among the most important factors that influence consumer acceptability and demand for fish products. Consumers have identified farmed fish as less complex and lacking “sealike” or “sea-fresh” flavors and aromas.